BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

1. Preparation

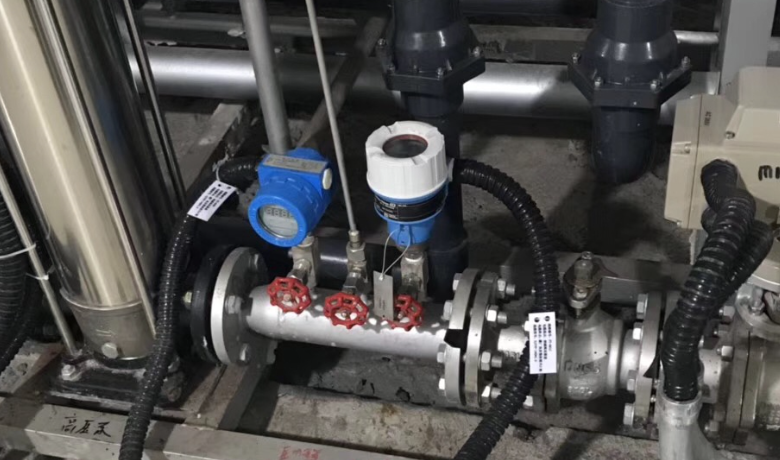

The pressure source is connected with the self-made joint through the rubber tube, the balance valve is closed, and the gas path seal is checked, and then the ammeter (voltmeter) and the hand operator are connected to the output circuit of the transmitter, and the calibration begins after the power is preheated. We know that no matter what type of china pressure transmitter, its positive and negative pressure chambers have exhaust, drain valve or cock; This makes it convenient for us to calibrate the differential pressure transmitter on site, which means that the differential pressure transmitter can be calibrated without removing the pressure guide tube. When calibrating the differential pressure transmitter, first close the positive and negative valves of the three valve groups, open the balance valve, and then loosen the exhaust, drain valve or cock to empty, and then use the self-made joint to replace the exhaust, drain valve or cock connected to the positive pressure chamber; The negative pressure chamber is kept loose to make it open to the atmosphere.

2. Calibration of conventional differential pressure transmitter

First, the damping is adjusted to zero state, first adjust the zero point, and then add the full degree pressure to adjust the full range, so that the output is 20mA. The field adjustment is fast, and the rapid adjustment method of zero point and range is introduced here. When the zero is adjusted, it has almost no effect on the full degree, but when the full degree is adjusted, it has an effect on the zero point, which is about 1/5 of the range adjustment without migration, that is, when the range is adjusted upward by 1mA, the zero point will move upward by about 0.2mA, and vice versa.

3. Calibration of intelligent differential pressure transmitter

It is not possible to calibrate the smart transmitter using the above conventional methods, because this is determined by the HART transmitter structure principle. Because the intelligent transmitter is between the input pressure source and the generated 4-20mA current signal, in addition to the machinery and the circuit, there is also the calculation work of the microprocessor chip on the input data. Therefore, the adjustment is different from the conventional method.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist