BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

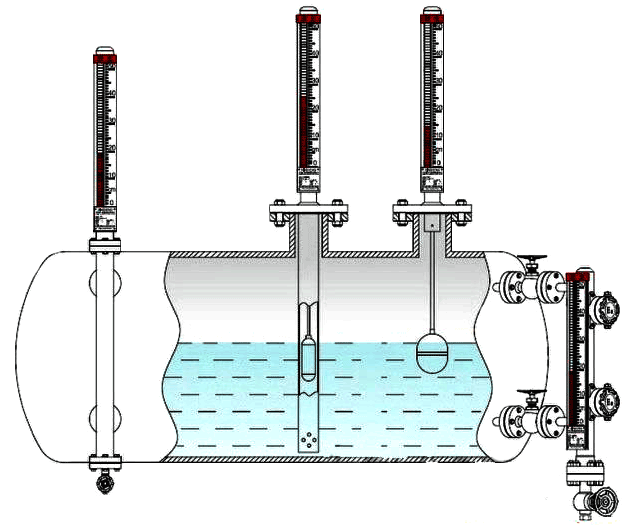

Magnetic Flap Level Gauge works according to the principle of buoyancy and magnetic coupling.

When the liquid level in the vessel under test rises and falls, the magnetic float in the measuring conduit of the liquid level meter also rises and falls, and the magnets in the float are transferred to the magnetic flip-flop indicator through the magnetic coupling, and the magnetic flip-flop indicator drives the red and white flip-flop to turn over 180°, and the flip-flop turns from white to red when the level rises, and the flip-flop turns from red to white when the level drops, and the red/white junction of the magnetic flip-flop indicator is the actual height of the liquid level.

Magnetic flap level meter is usually installed according to the user's environment selected, there are side-mounted, top-mounted, hanging the three ways to install. Magnetic flap level meter has a variety of names, such as magnetic float level meter, magnetic flip column level meter, the principle of similar, an amount of instrumentation according to custom collectively referred to as the magnetic flaps. Magnetic flap level meter fault repair must first inquire about the working principle, the basic knowledge of the product as well as the characteristics, in order to better deal with the fault in a timely manner. An amount of instrumentation combined with many years of experience summed up the magnetic flip-plate level meter fault repair examples to share with users fault checking and processing the following eight kinds of fault phenomena common in the use of magnetic flip-plate level meter, this site for these fault phenomena at the same time given the corresponding programme description, the content is summarized below:

1、Top-mounted magnetic flip-flop level gauge only indicates red at the gas-liquid level demarcation place, and indicates white below the liquid level. Troubleshooting: When the magnetic steel was brushed outside the site, the flap turned over normally; disassembling and checking found that the float and the connecting rod were detached.

Troubleshooting: Re-install the connecting rod and float connection, the liquid level indication is normal.

Maintenance Summary: top mounted flip-flop level meter magnet is not in the float, the float is only connected to the connecting rod, the connecting rod and the upper measuring conduit magnet into one, when the level changes, the float drives the connecting rod to make the magnet up and down in the measuring conduit to drive the indication of the surface of the red, white magnetic plate flip. When the float and the connecting rod off instantly, the connecting rod under the action of self-weight quickly fall, the magnetic flip-flop has not had time to flip from red to white, the magnet has left the flip-flop, the flip-flop and back to white. This is the reason why all the indication below the liquid level is white.

2、Top-mounted magnetic flip-flop level gauge indication and the actual level deviation is very large, and the change is slow. Failure to check: with a magnet in the level meter plexiglass cover up and down brush, the flip-flop can be converted normally, suspect that the float has a problem. Contact with the customer after parking for inspection and processing.

Troubleshooting (a): inspection found that the float and the connecting rod with a lot of dirt, after cleaning the instrument back to normal.

Maintenance Summary: Check the vertical level meter up 50cm, under normal circumstances, the indication of the magnetic flap should be down 50cm, but the indication is basically unchanged. Check again only to find dirt attached to the connecting rod and float, resulting in slow float action, resulting in slow display failure.

Troubleshooting (b): After cleaning the measurement conduit and float, the display returns to normal.

Maintenance Summary: magnetic flap level meter display is not allowed, the level jump, DCS trend curve straight line and other phenomena, a lot of dirty float, the measured medium viscous and crystalline; to stop before disassembly to check, clean or deal with.

3, magnetic flap level meter remote display is not normal, in the paperless recorder on the phenomenon of jumping or drawing a straight line. Failure to check: with a magnet in the flip-flop level meter up and down brush, the flip-flop can be converted to normal, but the display of changes in the instrument is not sensitive, no change after the sewage. Calibration is the problem of the float, disassembly and inspection found that the measurement of the inner wall of the conduit and the float with a lot of black dirt.

4, the liquid level changes, the magnetic flap level meter will not act first observe the indication of the liquid level meter, the magnetic flap level gauge display does not match, to determine the process liquid level is normal, the flap level meter can be flushed with sewage, sewage should be the first to close the upper part of the sampling valve, sewage process, open, close the valve must be slow, sewage failure remains, the magnet can be used to magnetism from the bottom up to the flip flop, the flip flop can be a normal change, there is no problem with the flip flop. There is no problem with the flap. In the magnetic attraction of the flap can not change with, should check the glass or plastic guard plate there is no deformation, guard plate deformation will cause the flap axis is not concentric and can not be flipped. Float in the magnetic steel used for too long, magnetic weakening, float in the magnetic steel and the flip-flop between the loss of magnetic connection between the small magnet, there will be a flip-flop will not act on the fault.

5, the magnetic flap indication confusion that is usually referred to as "chaotic magnetic" phenomenon. Magnetic flip-flop indication of the reasons for confusion: the flip-flop surface of the small magnetic steel magnetism is weakened, will produce varying degrees of "chaotic magnetic" phenomenon; with the improvement of the quality of the instrument with the magnetic steel, magnetic stability can be improved, compared with the past the probability of this type of failure is also greatly reduced.

Measurement of easy to vaporise media level, stable working conditions when the measured media gas phase and liquid phase conversion to reach equilibrium, then the level measurement value is normal. However, when the liquid is pumped out of the tank, the space above the liquid surface increases, the gas phase pressure decreases, there will be a piece of liquid vaporization, there will be a large number of bubbles, small bubbles rise in the process of convergence into large bubbles, large bubbles into the level meter measurement conduit, it may form a rising gas phase section, the gas phase section meets the floats in the process of rising, the gas will be from the floats around the passage, so that the floats are moving too fast, and the measurement of the conduit outside the Magnetic flip-flop loses its magnetic connection, which will cause the phenomenon of "chaotic magnetism", and the level indication will be chaotic. If the phenomenon of "chaotic magnetism" occurs, a magnet can be used to magnetically attract the flap, so that the flap can change normally.

6, the magnetic flap level meter level display deviation In the production due to various reasons will be mixed with many bubbles in the liquid phase, the liquid with gas phenomenon will change with the changes in production when the liquid with gas medium into the level meter measurement conduit, the measurement of the density of the medium inside the conduit will change, the buoyancy of the floats will change, the float will change the position, the flip-flop indicator will produce the level indicated by high or low error, reflected through the magnetic flap level gauge will also be high or low on the DCS display. The level indicated by the flip-flop indicator will have the error of high or low, which will be reflected in the display on DCS through the magnetic flip-flop transmitter. At this time, only contact with the process, improve the operating conditions to eliminate or reduce the phenomenon of liquid with gas.

7, the flip-flop remote signal and in situ indication of the level is not consistent First check the magnetic flip-flop transmitter, power supply voltage, signal line is normal; should also check the reed switch and resistance components whether there is poor contact, short circuit, open-circuit faults; interference by other magnetic fields will make the reed switch inaccurate, leading to changes in the nominal resistance value of the level of liquid level display deviation faults. Reed switch sticking and not releasing is also a common fault, just gently tap the measurement conduit ordinary can eliminate this fault.

Intelligent magnetic flip-flop transmitter output current more than 20mA or less than 4mA, there may be alarm signal output value, you can check the fault with the help of self-diagnostic function, according to the prompt information on the symptoms of the treatment.

8, the valve accessories fault checking and handling Magnetic flip-flop level meter is prone to blockage, measuring conduit dirt impurities in excess, will make the float jams and inflexible phenomenon, reflected in the display instrument that is the level of change is slow or across the change, can be flushed through the sewage to solve the block, if it is too dirty or excessive oil can be accessed through the upper venting valves of water or steam, gasoline to clean the float and measuring conduit.

Installation of the level meter flange connection bolts must be tightened, to diagonally tighten the bolts, in order to avoid uneven tightening of the flange gasket leakage. Spool packing should be appropriate, not only can not appear leakage but also to switch flexible. Used in high temperature, corrosive media place of the valve is prone to problems, should strengthen the inspection or regular replacement of the valve.

When the level meter is put into operation, the upper sampling valve should be opened first, and then slowly open the lower sampling valve, so that the medium smoothly into the measuring conduit, should avoid rapid impact of the medium when put into operation float, caused by the float violent bumps affect the correctness of the display. Drainage should first close the lower sampling valve, and then open the drain valve, so that the level in the measuring conduit down, and then open the lower sampling valve. For erosive, toxic and other special liquid discharge should be strictly in accordance with the operating procedures.

There is a venting valve on the upper part of the measuring conduit of the magnetic flip-flop level gauge, which is used for venting in order to prevent long time working, the measuring conduit contains gas, and the float can not work normally. Some products do not have a venting valve, but a silk plug, but the role is similar.

Magnetic flap level meter also belongs to a kind of level meter, for the field of magnetic flap level gauge failure also need to be familiar with the principle of the product junction and performance based on carry out, flap level meter in practice may be due to a single component or multiple components at the same time out of the problem caused by the flap level meter failure, so users must be in-depth inquiring about the product knowledge of the magnetic flip flop level meter for better application.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist