BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

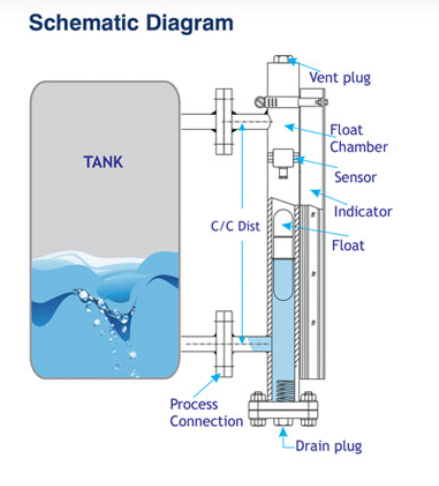

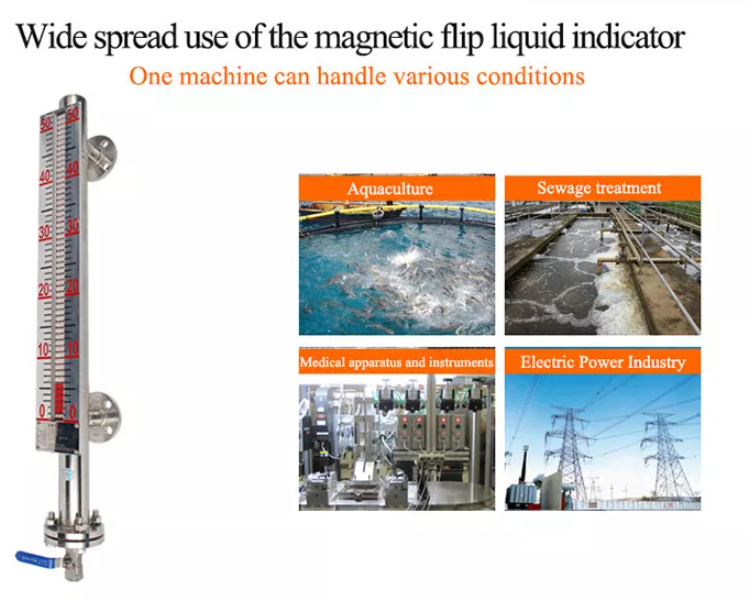

As a continuous liquid level measuring instrument, the magnetic flap level gauge is widely used in industrial production. This is inseparable from its simple structure, convenient installation, intuitive display, long visual distance, and it is very suitable for medium level measurement in storage tanks, storage tanks and other containers. However, due to the wide applicability of the magnetic flap level gauge, various working conditions are very different, which puts forward higher requirements for the purchase of the magnetic flap level gauge.

Magnetic flap level gauge

In general, the following points should be paid attention to when purchasing a magnetic flap level gauge:

1. Have a basic understanding of the medium measured by the magnetic flap level gauge

The user of the instrument should have an understanding of the working principle and basic structure of the magnetic flap level gauge, and confirm whether the viscosity of the measured medium is suitable for measurement with the magnetic flap level gauge.

1. The viscosity of the medium is usually less than 0.4Pa.s, and the density of the medium is generally 0.5-2.0g/cm³. The density of the medium is too low, and the processing of the magnetic float is more difficult.

2. If the density is too high and the liquid is thicker, the fluidity will be poor, and the resistance of the float moving up and down in the measuring tube body will increase, and the float will be easier to get stuck and cannot be measured.

3. Check whether the vibration frequency of the environment is less than 25Hz and the amplitude is less than 0.5mm, otherwise, the magnetic flap level gauge cannot work normally.

In short, when purchasing and selecting a magnetic flap level gauge, you should first determine whether the magnetic flap level gauge meets the measurement requirements of the actual working conditions, to determine whether to purchase a magnetic flap level gauge and what type of magnetic flap level gauge.

2. Determine the installation method of the magnetic flap level gauge

When selecting a model, it should first be determined whether to install it by side installation, top installation, side top installation or top and bottom installation, and the installation method is determined, which also determines the basic structure of the magnetic flap level gauge.

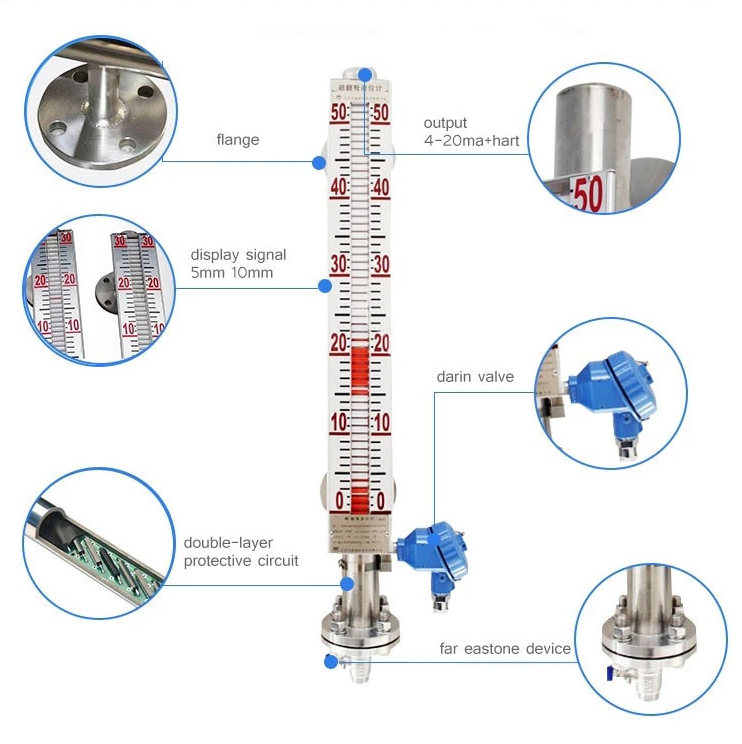

3. Determine the center distance of the process flange, that is, the measuring range of the magnetic flap level gauge

For the measurement range greater than 4m, considering the transportation problem, it is generally produced in sections; at the same time, the support flange needs to be added, and the user needs to provide the position parameters of the support flange to the manufacturer. At the same time, further determine the flange parameters such as the nominal size, pressure level, and sealing surface form of the process flange.

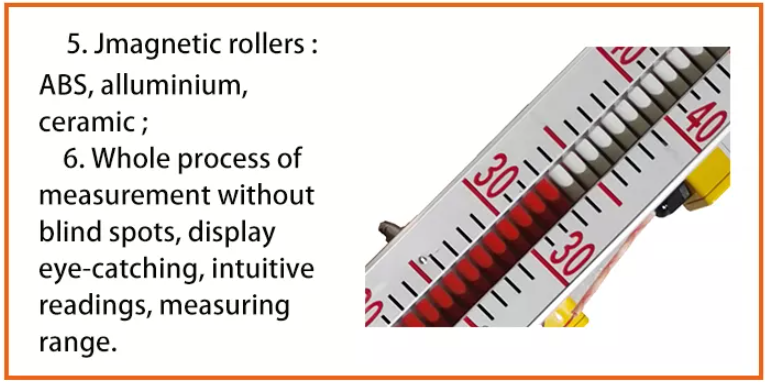

Fourth, determine the process pressure and process temperature

The size of the process pressure determines the size of the measuring tube, the wall thickness and the production requirements of the magnetic float (the pressure resistance of the float should be one level higher than the process pressure); the process temperature determines that the magnetic unit of the magnetic float adopts a high temperature It also decides whether to choose an aluminum alloy or a plastic medium for the display panel and flip, etc.; and the on-site environment determines the requirements for the protection level of the display panel.

5. Determine the type of medium being measured and whether it is corrosive

If the measured medium is weak corrosive medium, generally use 304 or 316L stainless steel magnetic flap level gauge. If the measured medium is weak acid and weak alkali wastewater discharged from industrial production, plastic type magnetic flap level gauge can also be used If the measured medium is strong acid and strong alkali, and the pressure is less than 1.6MPa and the temperature is less than 120℃, this kind of working condition generally adopts the PTFE-lined anti-corrosion magnetic flap level gauge.

6. Selection when the temperature of the measured medium is high or low and the viscosity is high

When the viscosity of the measured medium is high or the temperature is low and easy to crystallize, a steam or hot water jacket type magnetic flap level gauge can be used; when the measured medium temperature is high or the temperature is below zero and frost protection is required, it can be used Vacuum jacket type thermal insulation type magnetic flap level gauge.

7. Selection of magnetic flap level gauge when long-distance monitoring and recording are required

If you need to transmit the liquid level signal to the control center for remote monitoring and remote recording, you can choose a magnetic flap level gauge or magnetic switch with a remote transmitter, that is, a remote magnetic flap level gauge. Remote transmitters and magnetic switches are available in both explosion-proof and non-explosion-proof types according to the requirements of on-site working conditions.

In short, when purchasing a magnetic flap level gauge, users need to consider the installation method, medium name, medium corrosiveness, medium density, process pressure, process temperature, process flange connection type, flange connection type mentioned above Center distance, protection level and whether there are remote transmission and explosion-proof requirements, etc., to determine and select the magnetic flap level gauge

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist