BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

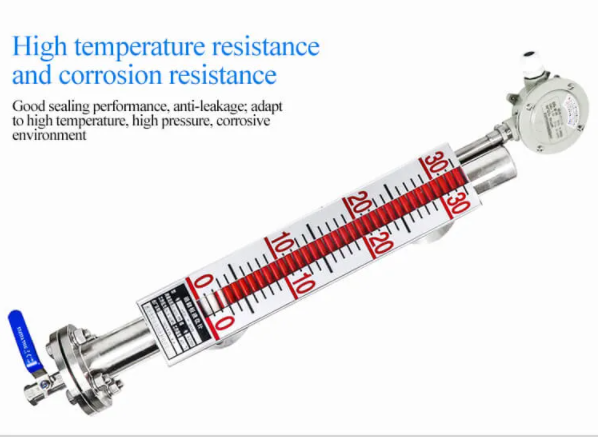

At present, liquid level measuring instruments are often used in industrial production, and magnetic level gauges are one of the commonly used ones.

In the process of using and managing the magnetic level gauge, we need the enterprise to use it in accordance with the requirements of relevant regulations, otherwise it will lead to inaccurate measurement and even damage to the level gauge.

Next, we will introduce the common sense that needs to be understood in the process of use.

First, when adjusting on-site, it is occasionally found that the float is not sensitive enough to float up and down. This is mainly caused by improper installation of the level gauge. At this time, pay attention to whether the center of the flange is on a straight line and whether it is perpendicular to the liquid surface. Generally, the angle with the liquid level is not less than 87 degrees. If it is too large, it may affect the smooth movement of the float.

2. After the magnetic level gauge is put into use, it can be found that the float will be sucked in a certain position. It is mainly caused by the fact that the liquid level device passing through the steel plate platform is too close to the steel plate. Therefore, passing through the steel platform device requires a special attention to the distance between the liquid level gauge connecting pipe wall and the platform cut edge. If the social distance is about 100mm, we can ensure that the enterprise will not affect the maglev.

3. If the output signal frequently interferes or interferes with pulses, check whether the shielding layer of the signal cable is grounded reliably and whether the working connection meets the resistance requirements. If none of the interference problems can be completely eliminated, they can be handled with a signal isolator.

4, when the liquid level gauge is put into use on site, special attention should be paid to opening the upper gate valve first, and then opening the lower gate valve. Because a thrust spring is installed at the bottom of the communication pipe of the liquid level gauge to maintain the float, otherwise, the effect of large differential pressure may cause damage to the float, resulting in the inability to use the level gauge control.

5. After the magnetic liquid level gauge is put into use for a period of time, the float is not easy to float, and the float movement is not sensitive. This is basically caused by iron filings on the magnetic float or some other fouling issue. Remove the media and then remove the float to remove iron filings or other dirt from the maglev.

6. Special attention should be paid to the use of the liquid level meter. Never use a strong magnet to pull the float up and down outside the connecting pipe to stop the inspection, otherwise it may cause the magnetic float to be magnetized, change the different polarities, and weaken the float's magnetic properties, making it more difficult achieve normal work.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist