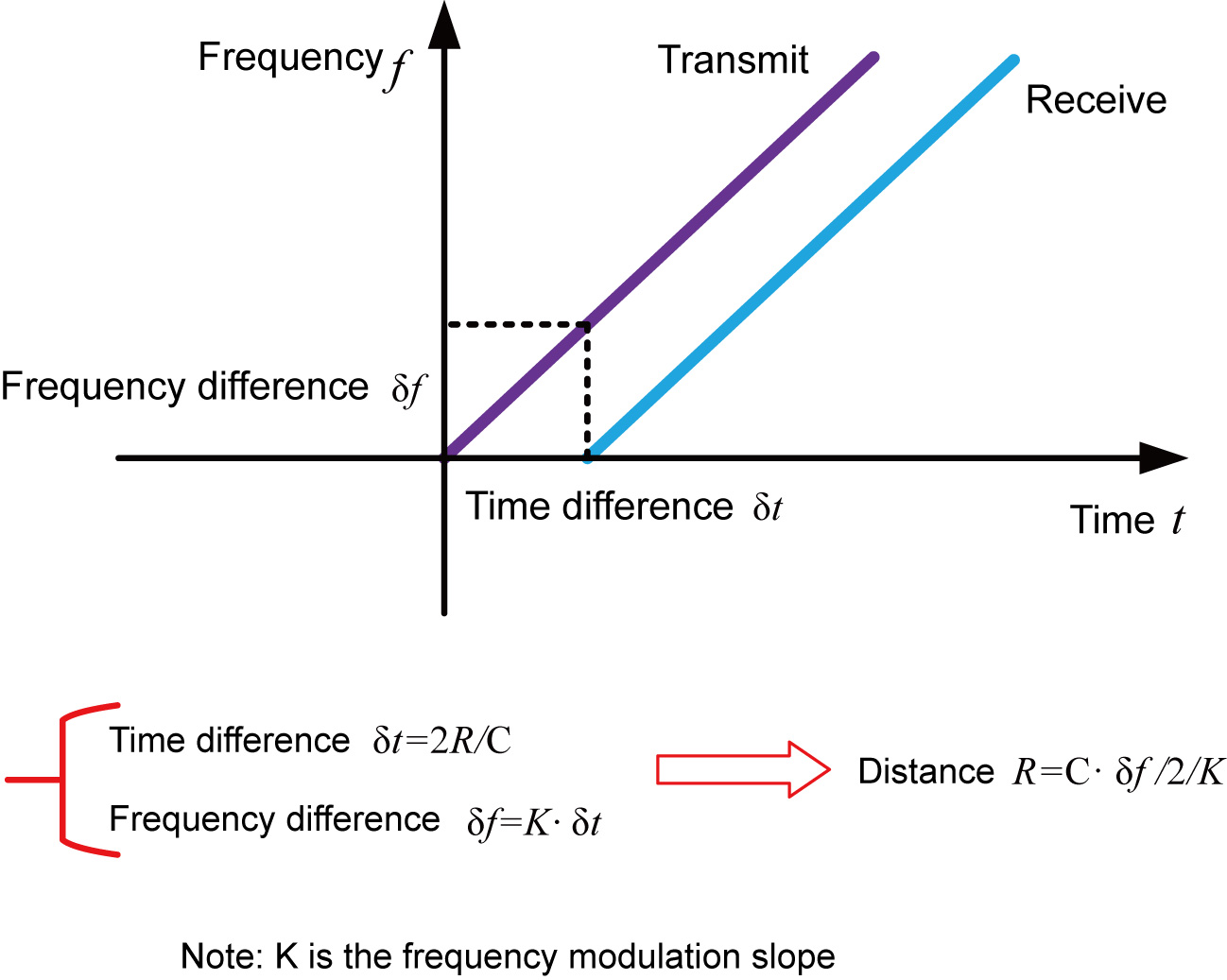

Principle

The general principle of the FM continuous wave radar level gauge is that the radar emits electromagnetic waves on the top of the tank, and the electromagnetic waves are received by the radar after being reflected by the medium. The frequency difference δf between the received signal and the transmitted signal is proportional to the distance R from the surface of the medium: R=C (speed)*δf (frequency difference)/2/K (frequency modulation slope). Because the speed of light C and the frequency modulation slope K are known, the frequency difference δf can be estimated to obtain the distance R from the radar installation position to the material surface, and then through the known total height of the tank, subtract the spatial distance from the radar to the material surface (referred to as Empty height) to get the height of the material level.

Characteristic

1. Millimeter-wave radar, with a measurement accuracy of up to ±1mm, and a minimum blind area of 0.1m.

2. The smaller antenna size satisfies the measurement of more working conditions.

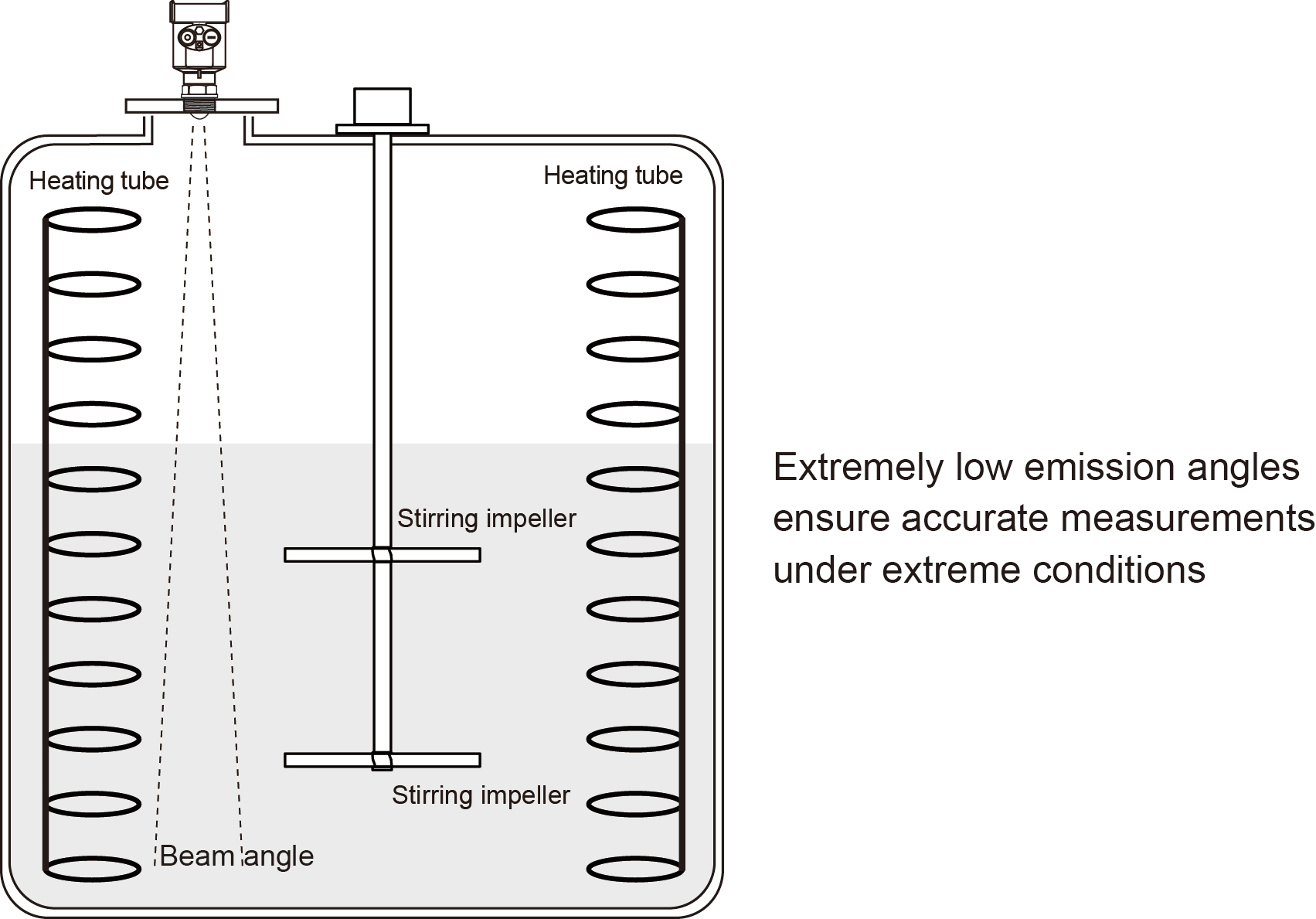

3. A variety of lens antennas, smaller launch angle, more concentrated energy, stronger echo signal, under the same industrial and mining conditions, compared to other radar products have higher reliability.

4. With stronger penetrability, it can be used normally even if there is adhesion and condensation.

5. The dynamic signal range is larger, and the measurement of low dielectric constant medium is more stable.

6. A variety of measurement modes, the radar reaction time in the fast measurement mode is less than 1S.

FMW-13 Product Introducion

Installation Requirements

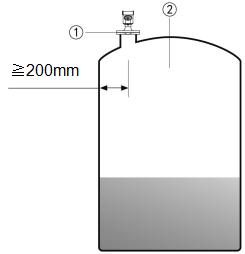

Installation method 1:Flange mounting

The meter should be installed at 1/4 or 1/6 of the diameter of the tank when using flange, and the minimum distance between the meter and the tank wall should be more than 200mm.

Note: ①Datum

②Container center or axis of symmetry

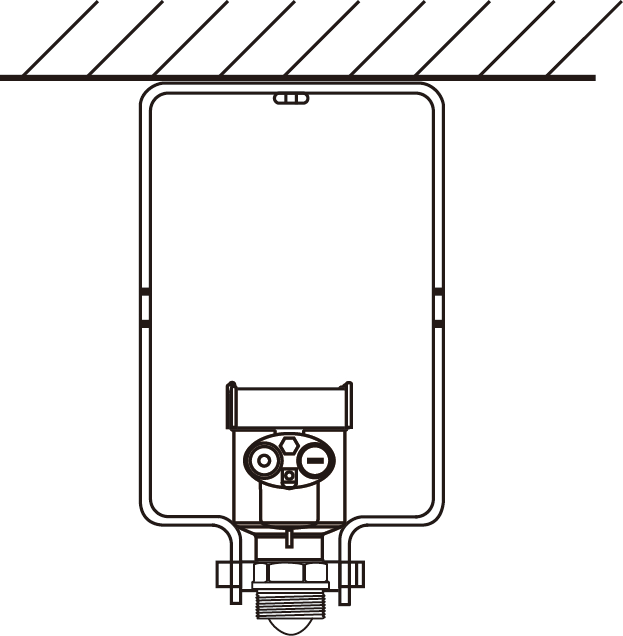

Installation method 2:Hoisting

(selected according to specific installation conditions)

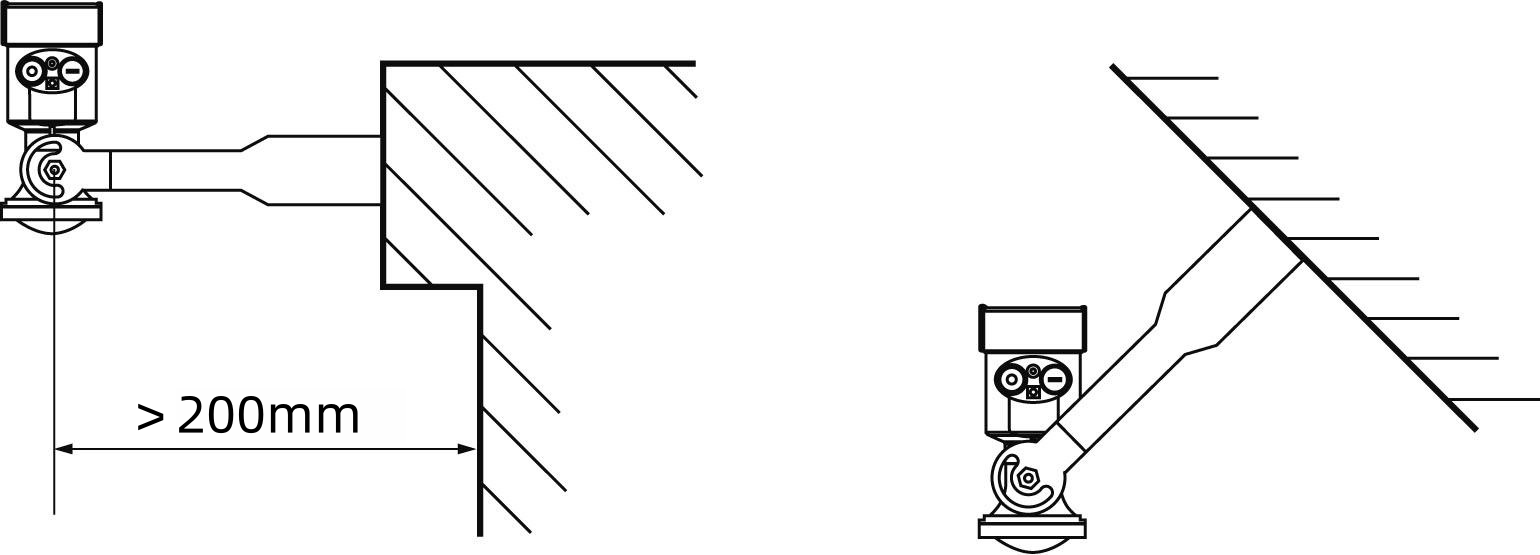

Installation requirements:

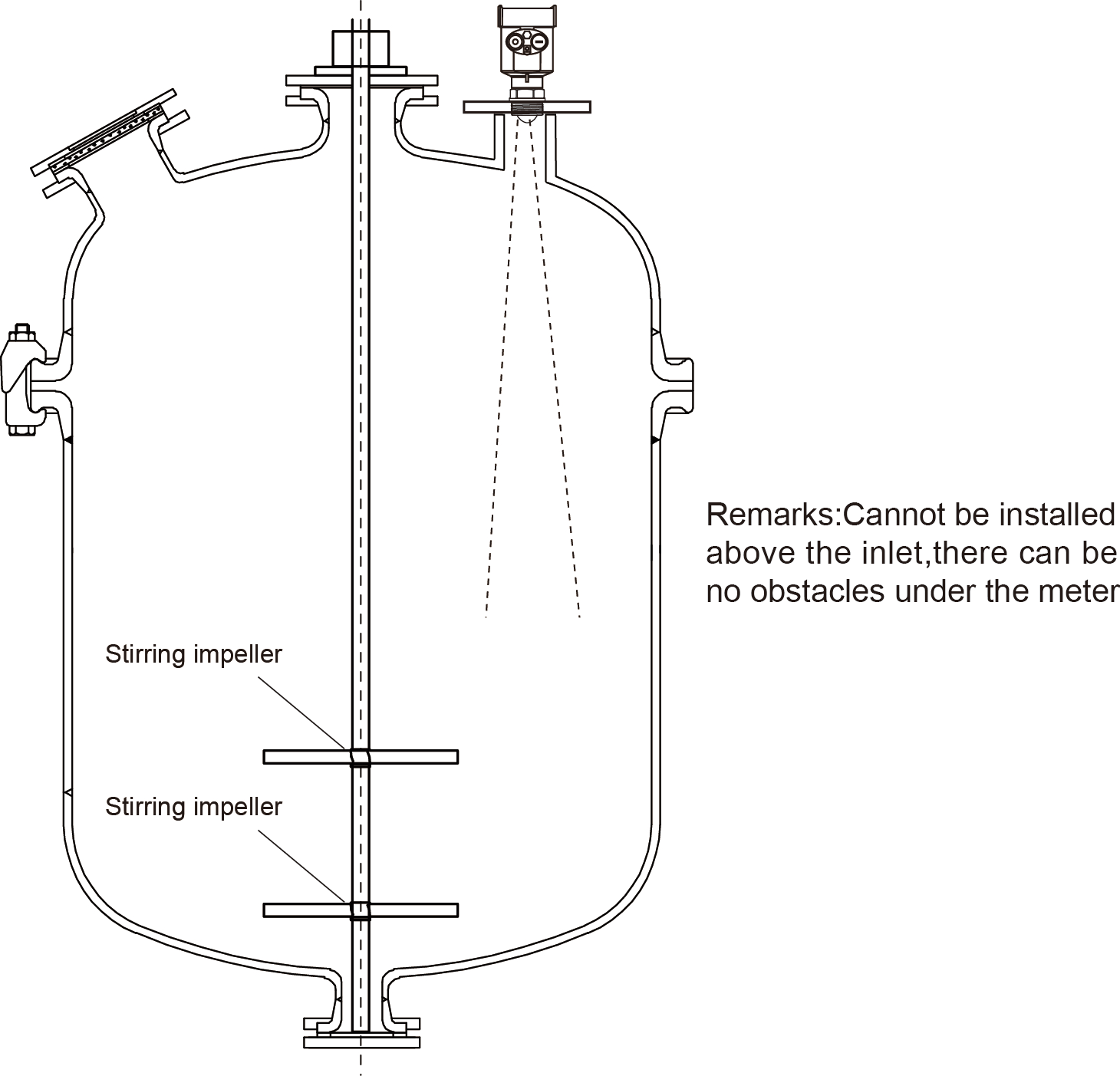

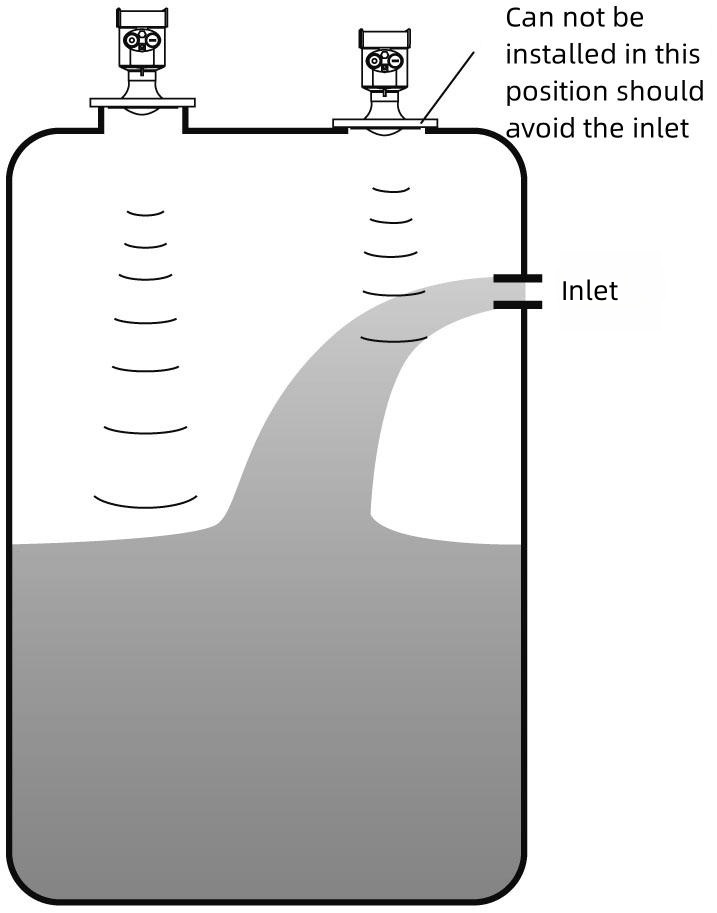

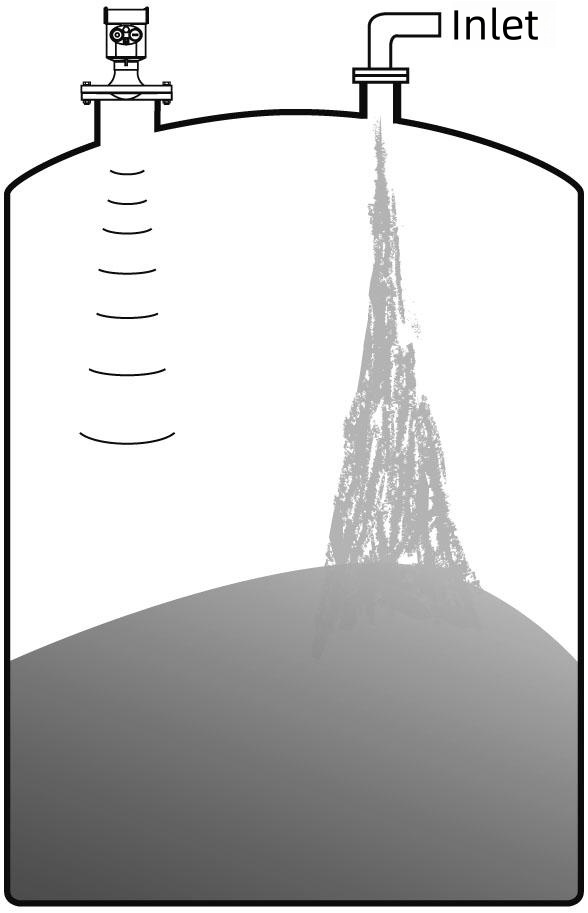

When installing the instrument, avoid installing it above the material inlet, and try to avoid various objects that affect the signal, such as stirring paddles, etc.

Under extremely complex working conditions, the instrument can work normally with the radar installation point as the center and no obstacles in the area with a radius of 20 cm.

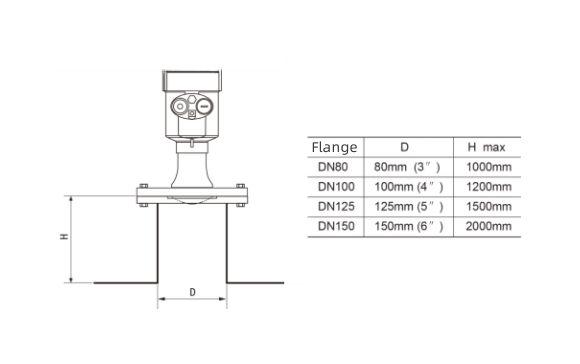

Schematic diagram of installation and takeover

The maximum installation stub height H max depends on the installation stub diameter D and the product launch angle.

Long installation and takeover will affect radar performance.

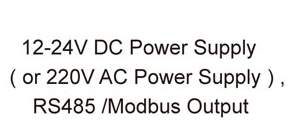

Elecitical Connections

Power Supply

| (4~20) mA(2-wire) | The power supply and the output current signal share a two-core shielded cable. See technical data for specific power supply voltage range. |

(4~20) mA(4/6-wire) | The power supply needs to be supplied separately, and the power supply and the current signal use a four-core shielded cable (the current signal and the RS485 interface can be output at the same time, and the output needs to use a six-core shielded cable). |

| Modbus-RS485 | The power supply needs to be supplied separately, and the power supply and the digital use a four-core shielded cable (the current signal and the RS485 interface can be output at the same time, and the output needs to use a six-core shielded cable). |

Connection method

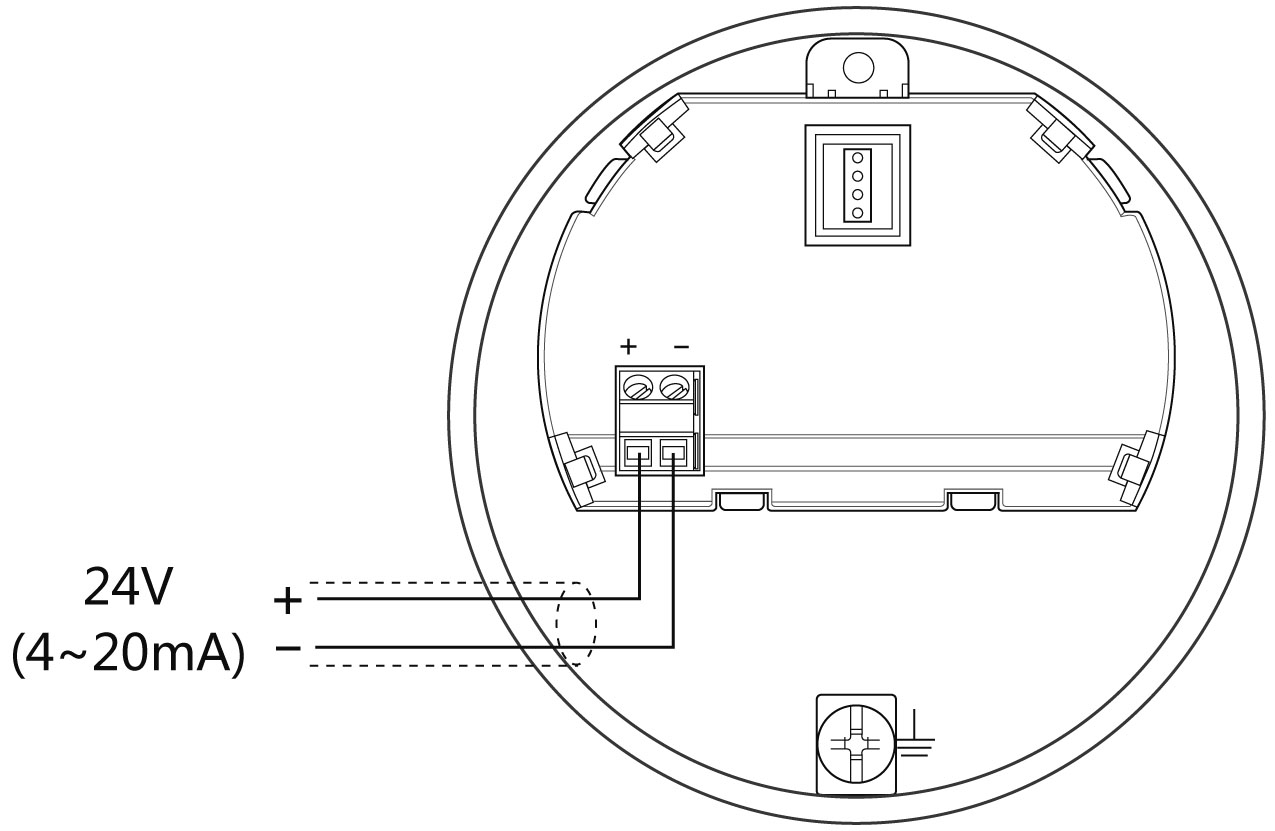

Ø 24V two-wire system wiring diagram is as follows:

Ø Two-wire and two-chamber wiring diagram shown on the side is as follows:

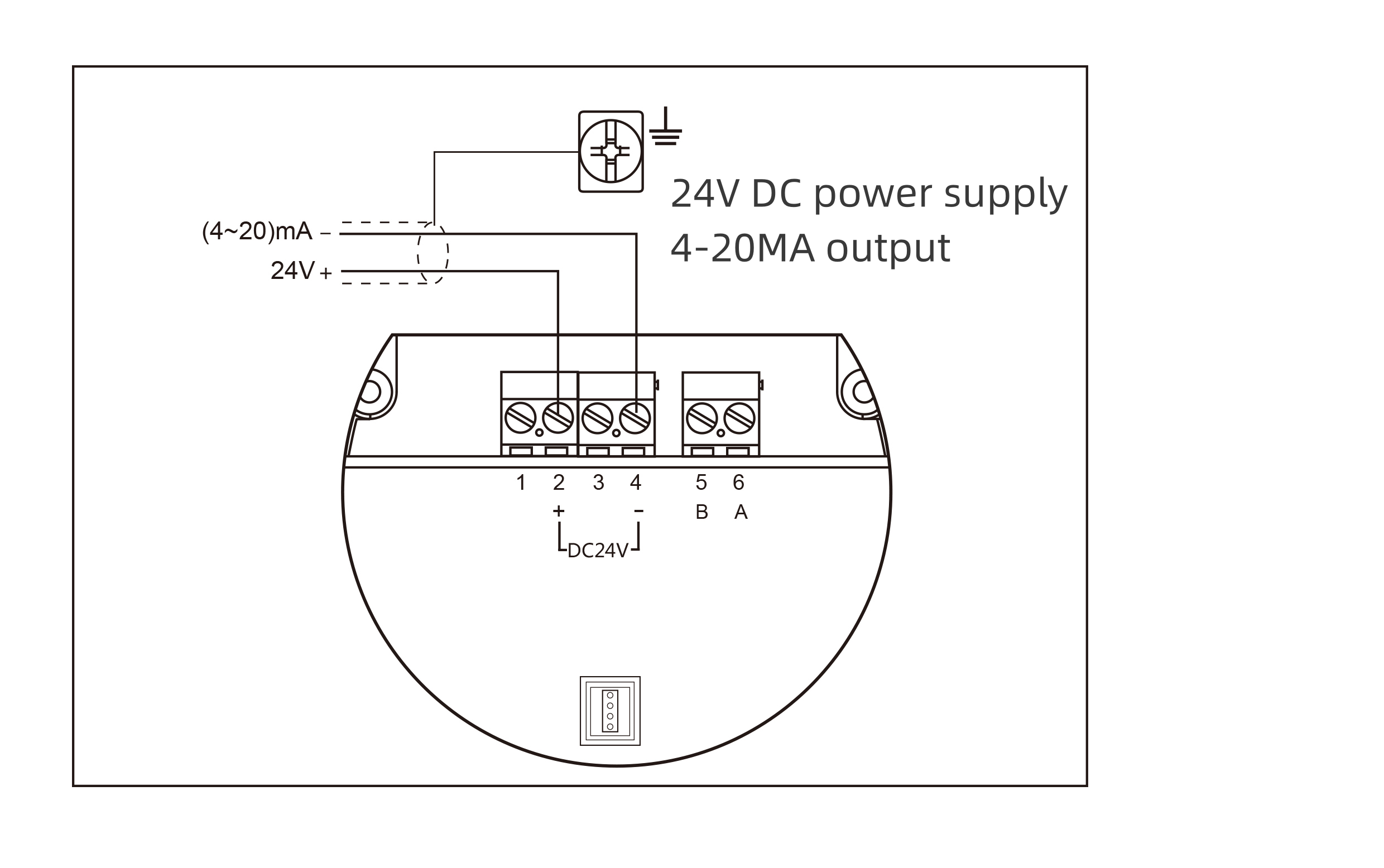

Ø Four-wire, two-room wiring diagram:

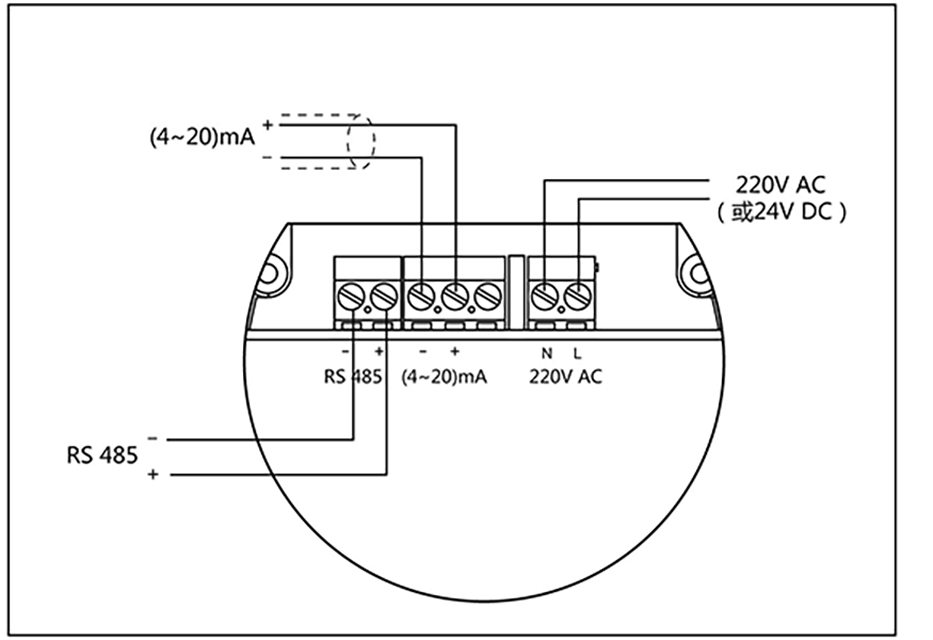

Ø six-wire wiring diagram of the four-wire system is as follows:

Safety guidance

Please observe the requirements of the local electrical installation regulations!

Please observe local regulations regarding the health and safety of personnel. All operations on the electrical components of the instrument must be performed by trained professionals.

Please check the nameplate of the instrument to ensure that the product specifications meet your requirements. Make sure that the supply voltage is the same as that on the instrument nameplate.

Protection level

This instrument fully meets the requirements of protection grade IP66/67. Please ensure the waterproof performance of thecable gland. As shown below:

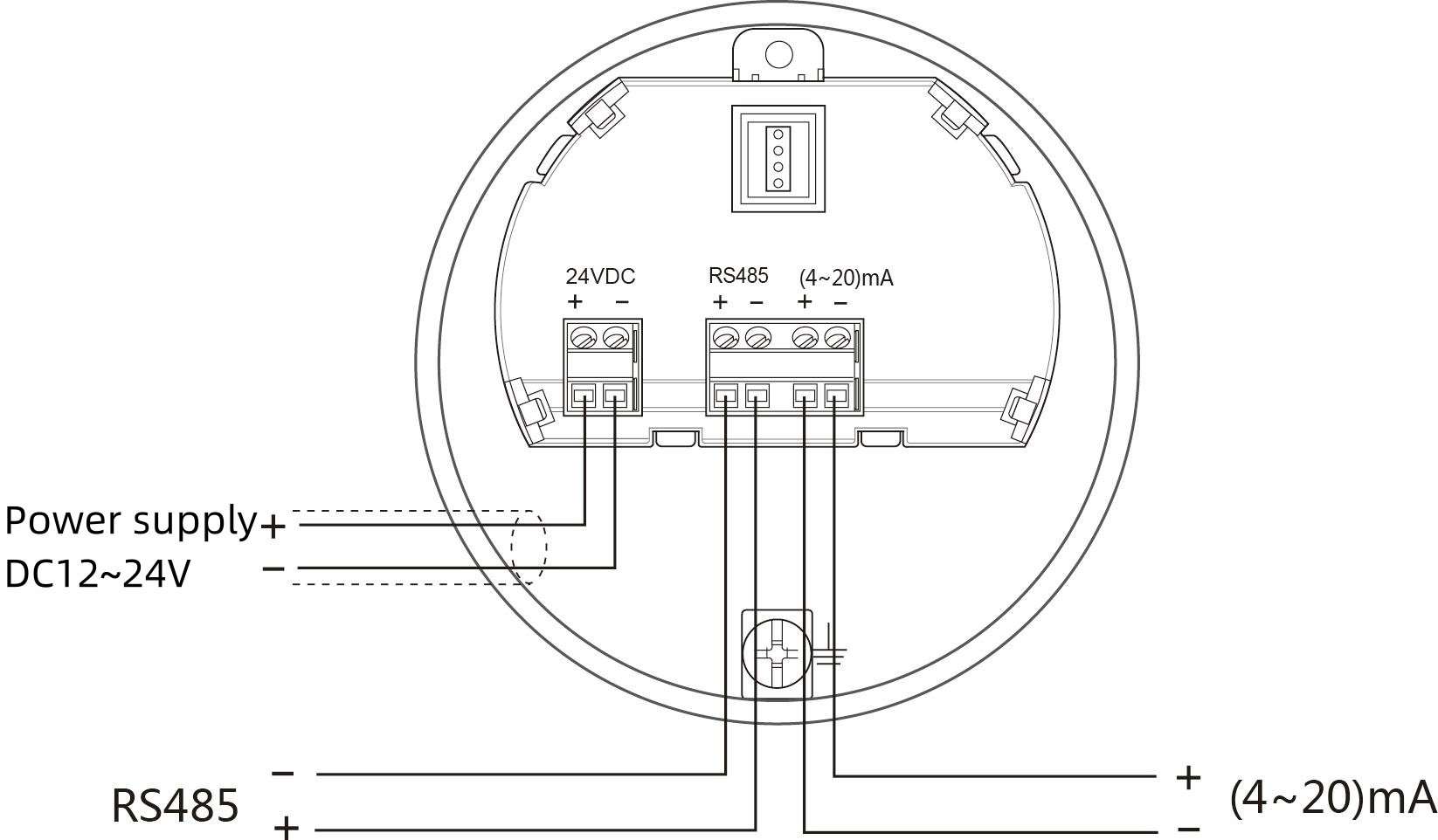

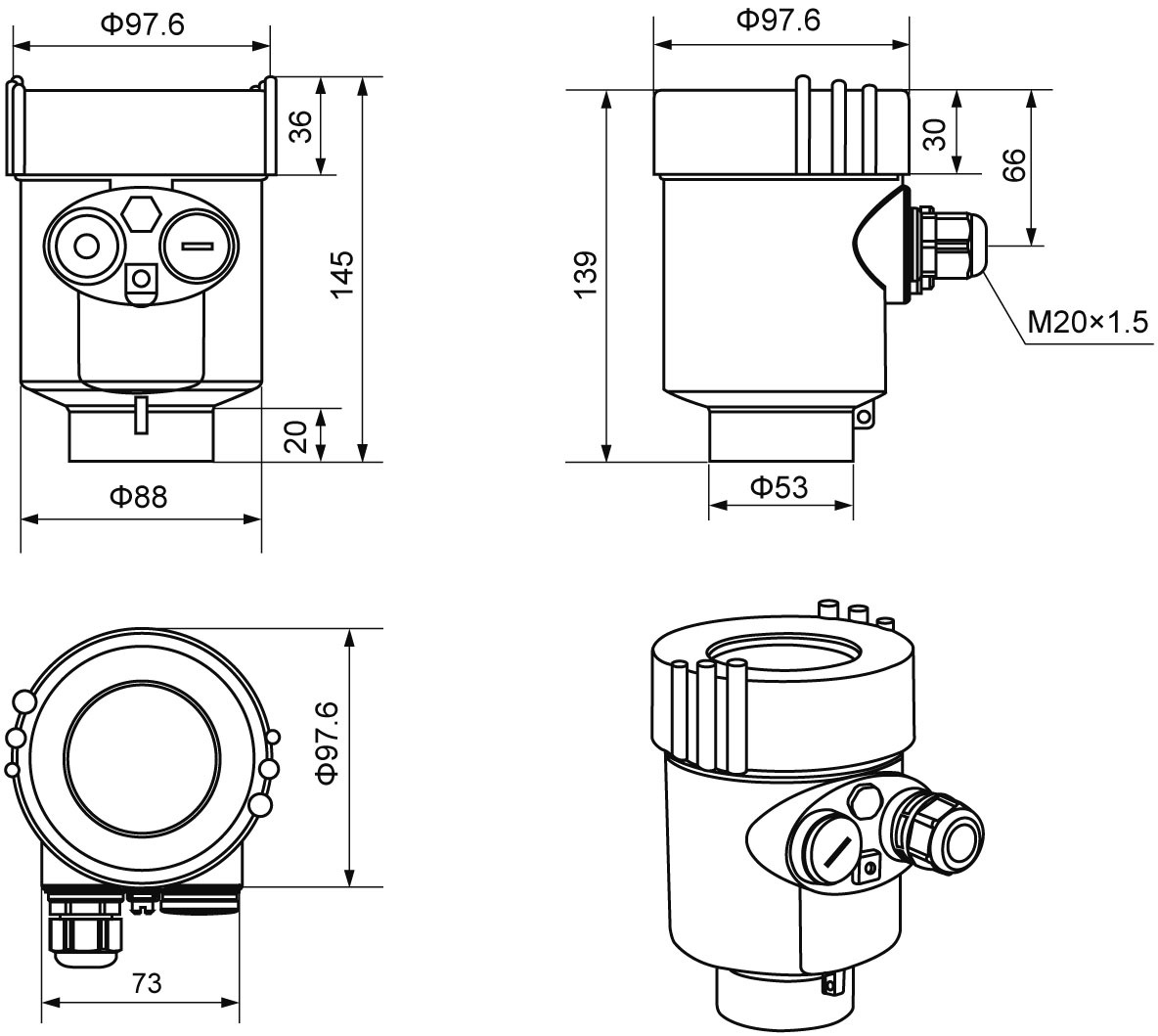

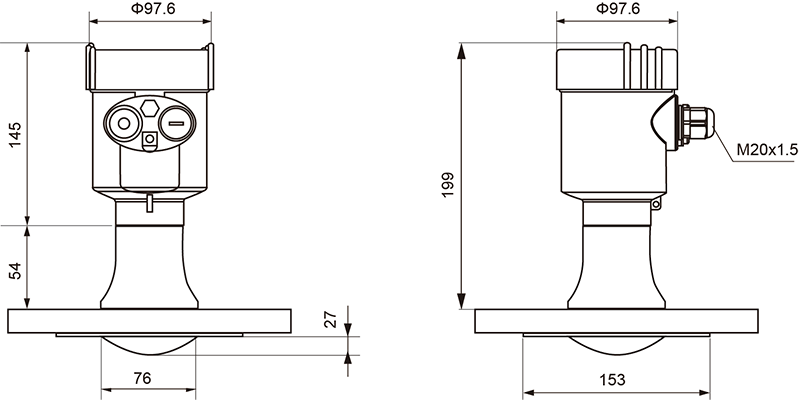

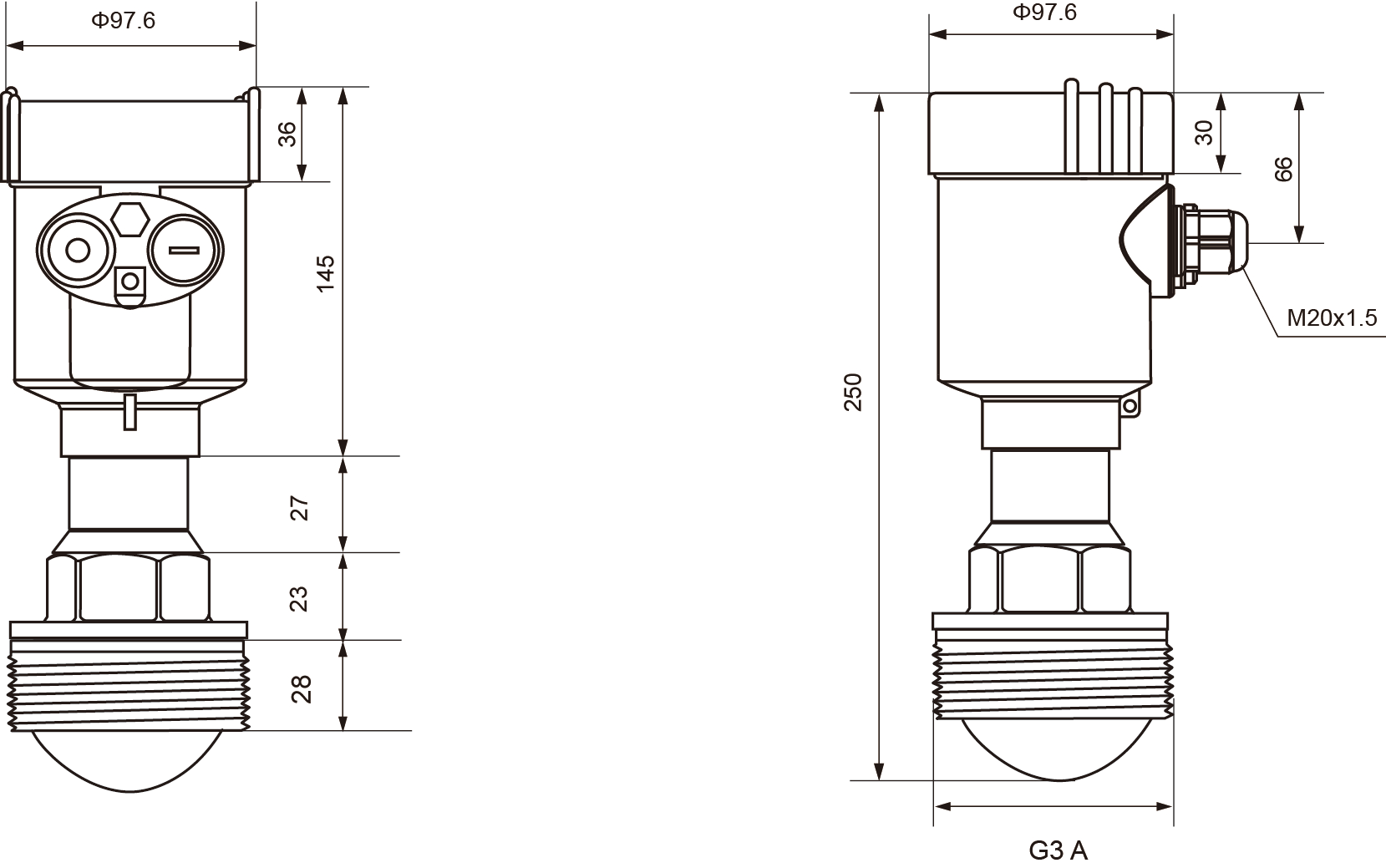

Structure Size

The outer casing size (unit: mm)

Aluminum case:

Stainless steel case:

Product Size (unit: mm)

Technical Parameters

Process Connection Flange / material PP, PTFE, stainless steel, stainless steel +PTFE flanging

Antenna Material PTFE

The outer shell Cast aluminum / stainless steel / plastic ABS

The seal between the shell and the shell cover Silicone rubber

Casing window Polycarbonate

The ground terminal Stainless steel

Power supply pressure

| 2-wire system (single cavity/double cavity) | (15-28) V DC Power dissipation max 80mA DC24V/ 2W Allowable ripple <100Hz Uss < lV (100~100K) Hz Uss < l0mV |

| Double chamber housing | (198~242)V AC 4-wire system 110V AC 4-wire system |

Cable parameter

Cable entrance / plug 1 M20×l.5 cable entrance

1 blind plug M20×l.5

Terminal Conductor cross section 2.5mm²

Output parameters

Output signal (4~20) mA /HART

Resolution 1mm

Fault signal current output unchanged;20. 5mA;22mA;3.9mA

Integration time (0~20)s, adjustable

Blind zone 0.1m/0.2m/0.3m

Maximum measuring distance 150 m

Measurement interval 1 second (depending on parameter settings)

Adjustment time about 1 second (depending on parameter settings)

Working storage and transportation temperature (-40~80) ℃

Relative humidity ˂ 95%

Pressure Max. 2.5MPa

Shockproof Vibration frequency (10~150) Hz,

Maximum vibration acceleration l0m/s²

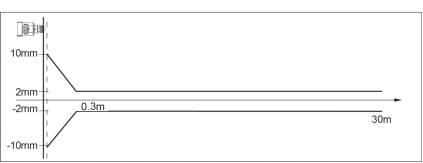

Meter Linearity

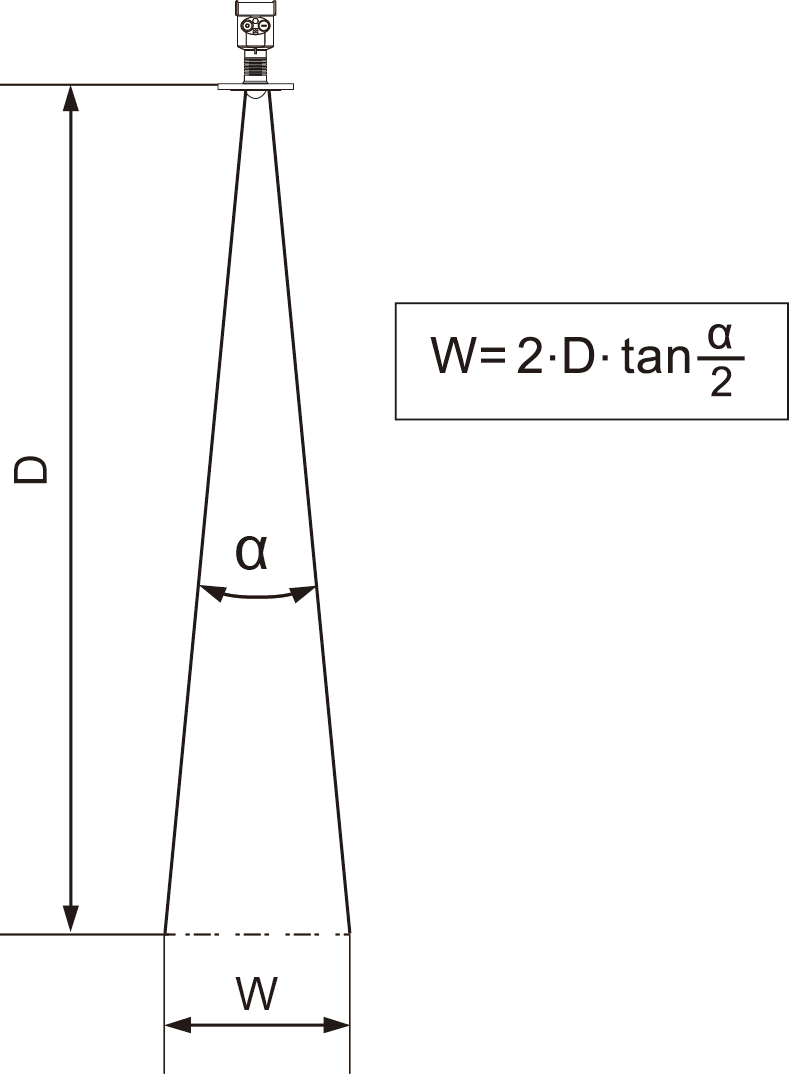

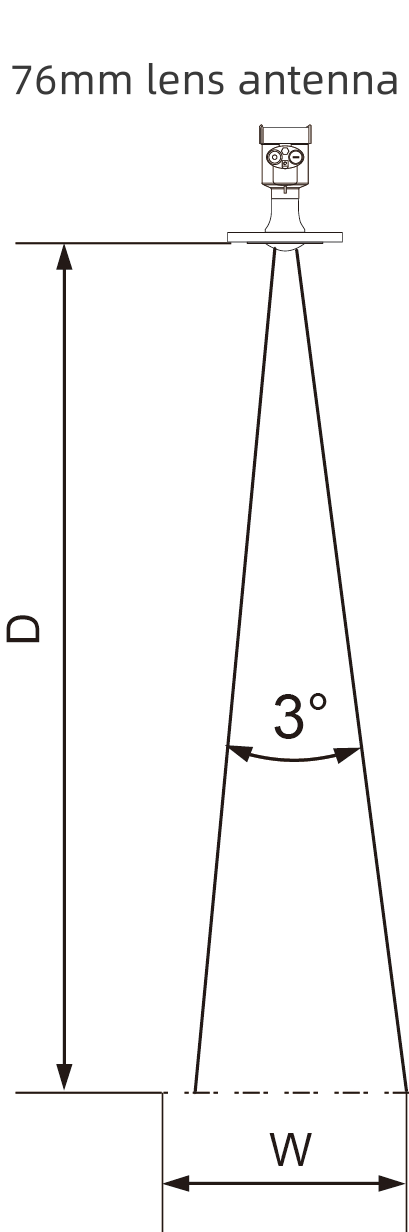

Beam angle

The beam angle is the beam angle when the radar wave energy density reaches half of its maximum value (3dB width). Microwaves emit signals outside the beam range and can be reflected by interference objects.

The larger the antenna size, the smaller the beam Angle alpha, the less the interference echo will be generated.

For more accurate measurements, avoid installing any internal devices (such as limit switches, temperature sensors, bases, vacuum rings, heating coils, baffles, etc.) within the signal beam range.

Gauge linear

Product Model Selection

FMW13 |

License | |||||||||||||||||||||||||

P Standard (Non-explosion-proof) I Intrinsically safe(Exia IIC T6 Ga) D Intrinsically safe+Flameproof(Exd ia IIC T6 Gb) | |||||||||||||||||||||||||

Process Connection / Material | |||||||||||||||||||||||||

1 G3.5A Thread 2 Flange≥DN80 (Stainless steel + PTFE) X Special customization | |||||||||||||||||||||||||

Flange option / material | |||||||||||||||||||||||||

| |||||||||||||||||||||||||

Antenna Type / Material | |||||||||||||||||||||||||

A 76mm filled lens antenna /PTFE | |||||||||||||||||||||||||

Sealing / process temperature | |||||||||||||||||||||||||

A FKM/(-40-110℃) B EPDM/(-40-110℃) Y Special customization | |||||||||||||||||||||||||

The Electronic Unit | |||||||||||||||||||||||||

1 (4~20)mA/HART protocol 24VDC 2-wire 2 (4~20)mA/HART protocol 220VAC 4-wire 3 (4~20)mA+RS485/Modbus protocol 12- 24VDC 6 wire | |||||||||||||||||||||||||

Shell material/protection grade | |||||||||||||||||||||||||

A Cast aluminum / Single chamber / IP67 B Cast aluminum / Double chamber / IP67 C Cast aluminum / Double cavity side view / IP67 D Plastic ABS / Single chamber / IP65 E Stainless steel 304 / Single chamber / IP67 | |||||||||||||||||||||||||

Cable Line | |||||||||||||||||||||||||

M M20×l. 5 N ½″ NPT X Special customization | |||||||||||||||||||||||||

Display programming | |||||||||||||||||||||||||

A Programming with display B With display programming / Bluetooth communication C Without |

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist