A bin level indicator (also referred to as a bin level sensor) is a device or system used to measure and monitor the level of a stored powder or bulk solid material in a bin, silo, hopper, or other container used as part of a bulk material handling process.

Working principle of grain bin indicator

The grain bin indicator operates on a sophisticated principle that combines both mechanical and electronic components to provide real-time monitoring of grain levels within storage bins. At its core, the grain bin indicators employs sensors—often ultrasonic or capacitive—to accurately measure the distance between the sensor and the surface of the stored grain. This measurement is then translated into data that reflects not only the current level of grain but also trends over time, allowing for efficient inventory management. Additionally, many modern indicators are equipped with wireless communication technology that transmits this information to a central system or mobile application, ensuring that farmers can monitor their storage conditions remotely. The integration of temperature and moisture sensors further enhances functionality by providing insights into potential spoilage risks, making the grain gauge bin level indicator an indispensable tool in optimizing agricultural operations and safeguarding harvests against losses.

Benefits of grain bin level indicator

A grain bin level indicator plays a pivotal role in enhancing the efficiency and safety of grain storage operations. By providing real-time measurements of grain levels within silos, this advanced monitoring technology minimizes the risk of overflow or underutilization, allowing operators to make informed decisions about when to harvest or sell their stored commodities. Moreover, a grain bin level indicator facilitates better inventory management by accurately tracking stock levels, which can lead to improved cash flow through timely sales and reduced spoilage risks. Additionally, integrating these indicators with automated systems allows for remote monitoring capabilities; this not only saves valuable time but also reduces labor costs associated with manual checks. The enhanced data visibility provided by a grain bin level indicator empowers farmers and agribusinesses to optimize their operations while maintaining compliance with industry standards for quality control and food safety.

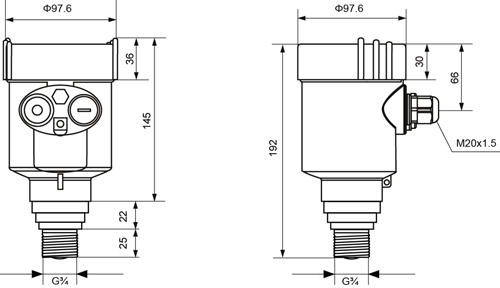

KD-FMW series silo level sensors are 80G FM radar type level measuring instruments with a measuring distance of up to 150 meters. The antenna is further optimized for processing and the new fast microprocessor allows for higher speed signal analysis and processing, making the instrument available for measurement of high temperature and high pressure and other environmental solids.

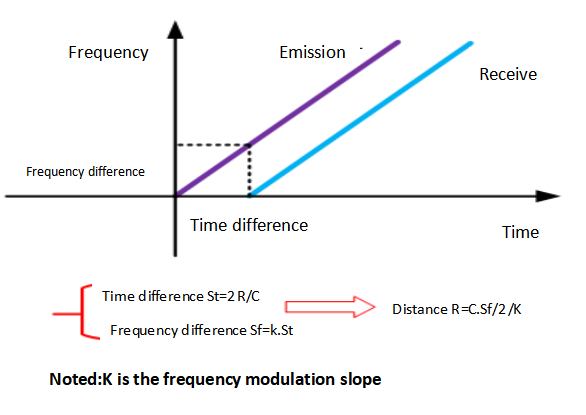

The general principle of frequency modulated continuous wave radar level meter is that the radar emits electromagnetic waves at the top of the tank, and the electromagnetic waves are received by the radar after hitting the medium and reflected. Because the speed of light C and FM slope K are known, so the frequency difference δ f is estimated, and the distance R of the material surface at the radar installation position can be obtained, and then the height of the material level is obtained by subtracting the spatial distance from the radar to the material surface (referred to as the empty height) from the known total height of the tank.

This instrument fully meets the requirements of protection class IP66/67.

This instrument fully meets the requirements of protection class IP66/67.

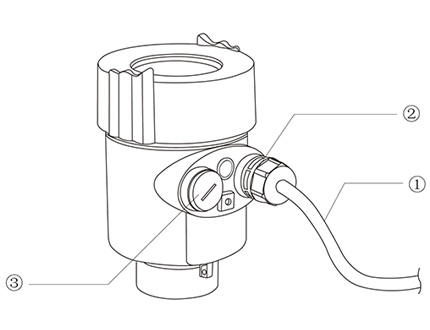

Please make sure that the cable sealing head is waterproof. As shown

How to ensure that the installation meets the requirements of IP67:

Please make sure that the sealing head is not damaged.

Please ensure that the cable is not damaged.

Please ensure that the cable used meets the requirements of the electrical

connection specification.

Before entering the electrical connection, bend the cable downwards to

ensure that water does not flow into the housing, see ①

Please tighten the cable sealing head, see ②

Please plug the unused electrical connections with blind plugs, see ③

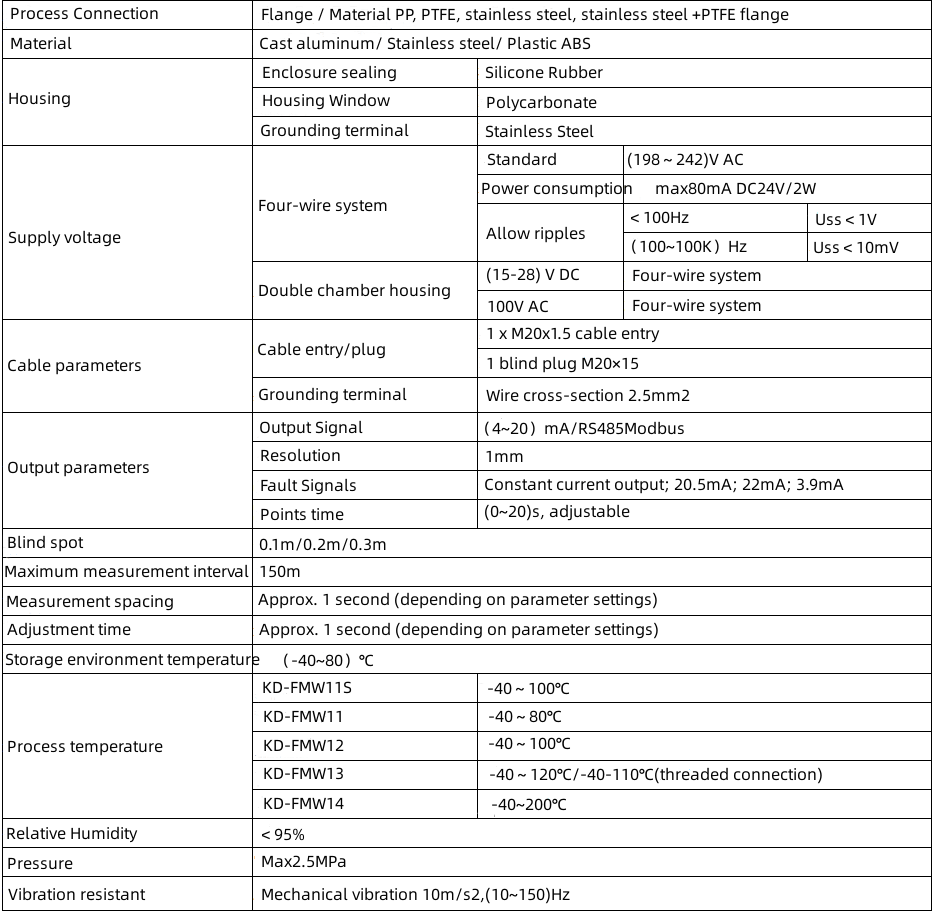

Measuring medium: liquid

Measuring medium: liquid

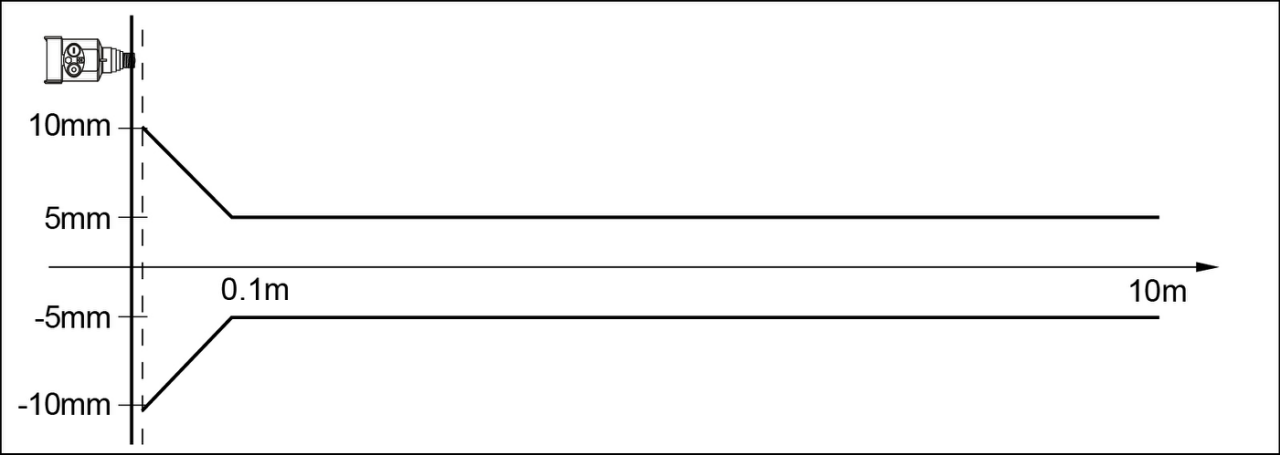

Measuring range: 0.1m~10m

Process connection: G¾A / ¾NPT thread / flange ≥DN 25

Process temperature: -40~ 100℃

Process pressure: -0.1 ~ 1.6 MPa

Accuracy: ±5mm

Protection class: IP67

Center frequency: 80GHz

Power supply: two-wire (DC24V) / four-wire (AC220V) / six-wire (DC12V~24V)

Housing: aluminum/plastic/stainless steel

Signal output: 2-wire 4.... .20mA / HART protocol / 4-wire 4.... .20mA /RS485 Modbus

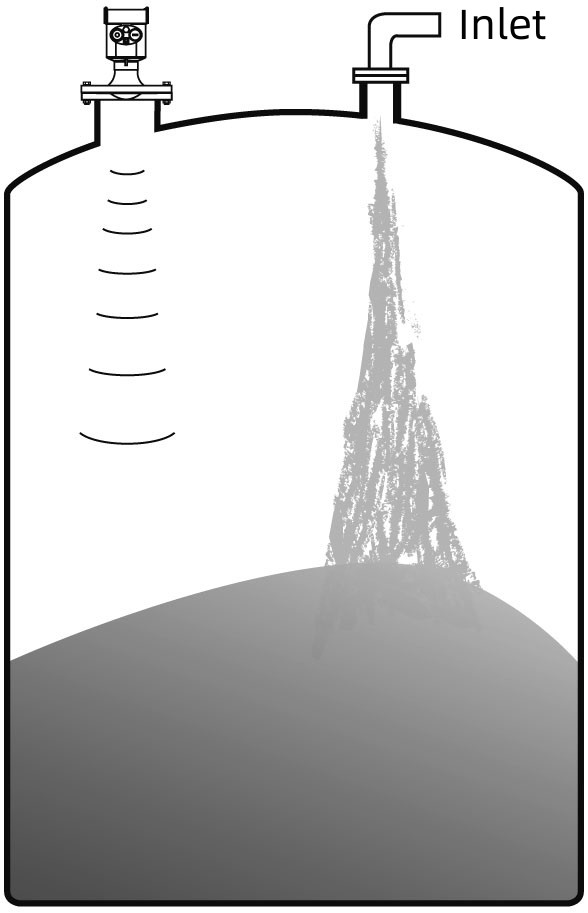

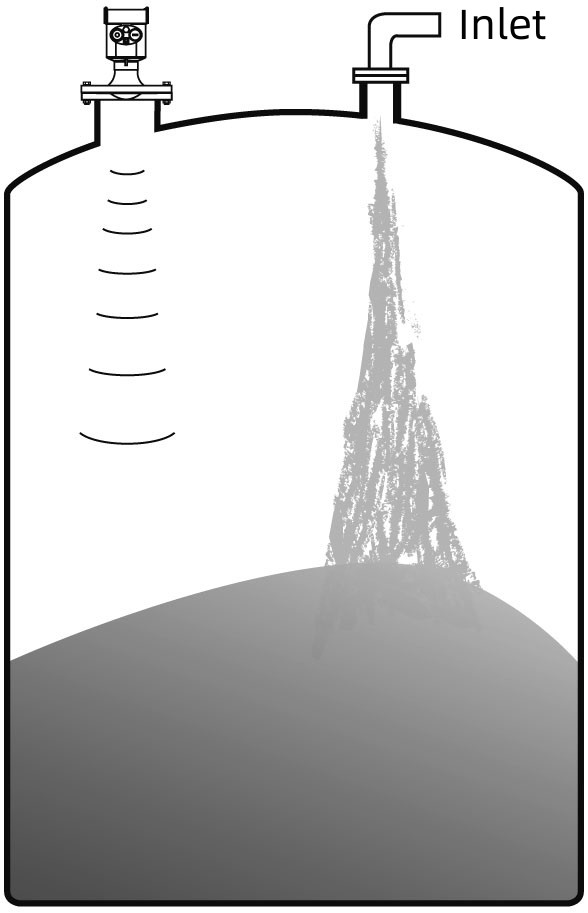

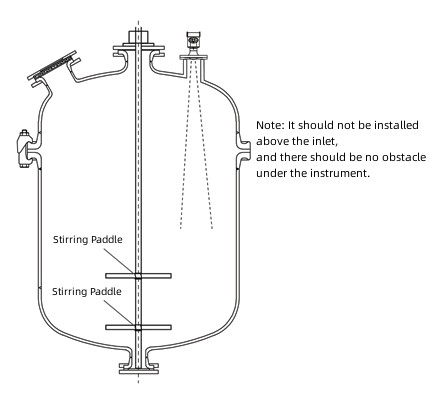

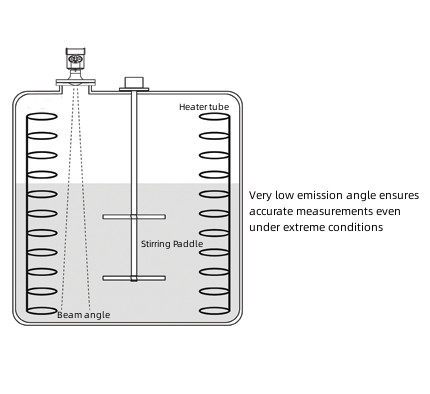

When installing the instrument, avoid installing it above the inlet, and try to avoid various objects that affect the signal, such as stirring paddles, etc.

● Under extremely complex working conditions, the instrument can work normally without any obstacle in the area of 20cm radius centered on the radar installation point.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist