BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Installation steps and precautions of magnetic flap level gauge

1: You must first understand the operating situation of your equipment and what the measuring medium is. Even if you do not know what material you need, our company can determine the material of the equipment according to the medium.

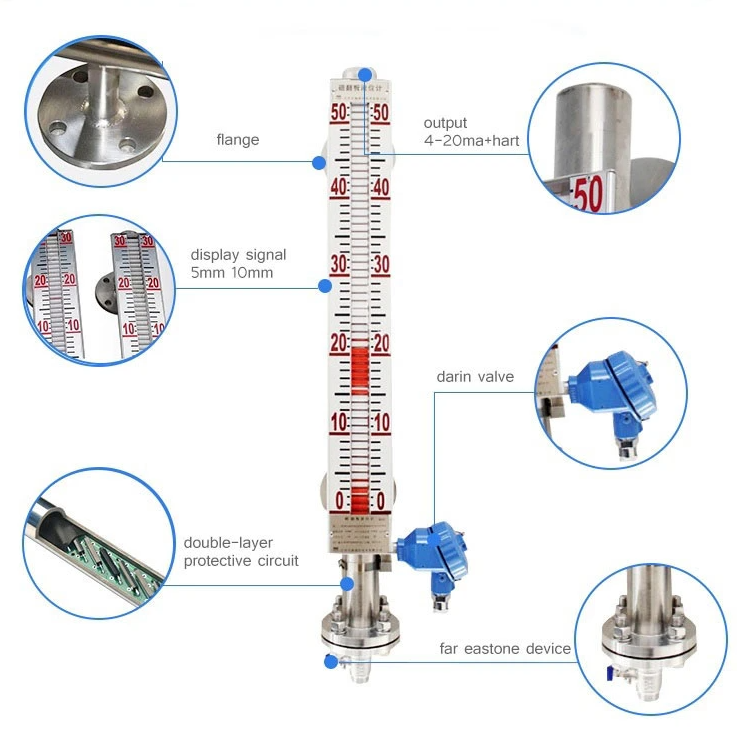

2: When equipped with remote transmission supporting instruments, the following requirements shall be met:

The remote transmission supporting instrument shall be close to the main pipe of the level gauge and fixed with stainless steel hoop (iron is prohibited);

The upper sensing surface of the remote transmission supporting instrument shall face and be close to the main pipe;

The zero position of the remote transmission supporting instrument shall be on the same horizontal line as the zero position indication of the liquid level gauge;

The wiring between the remote transmission supporting instrument and the display instrument or the industrial computer should be laid separately through the protective tube or with a shielded two-core cable;

After the wiring inlet hole of the junction box is laid, it is required to be well sealed to avoid the intrusion of rain, moisture, etc. which may cause the remote transmission supporting instrument to fail to work normally. The junction box shall be timely covered after maintenance or commissioning.

3: The main pipe shall be cleaned irregularly to remove impurities according to the medium conditions;

4: For the liquid level gauge exceeding a certain length (ordinary type > 3m, anti-corrosion type > 2m), it is necessary to add a middle reinforcing flange or ear plate as a fixed support to increase the strength and overcome its own weight;

5: The installation position of the magnetic flap level gauge shall be kept away from or away from the inlet and outlet of the material medium to avoid the rapid change of the local area of the material fluid, which will affect the accuracy of the liquid level measurement;

6: During the commissioning of the magnetic flap level gauge: first open the upper lead pipe valve, then slowly open the lower valve to allow the medium to enter the main pipe smoothly (during the operation, the medium shall not impact the float rapidly, causing the float to fluctuate dramatically, affecting the display accuracy), observe whether the magnetic red and white ball turns over normally, then close the lower lead pipe valve, open the drain valve, let the liquid level in the main pipe drop, operate according to this method for three times, which is normal, It can be put into operation (except for corrosive and other special liquids);

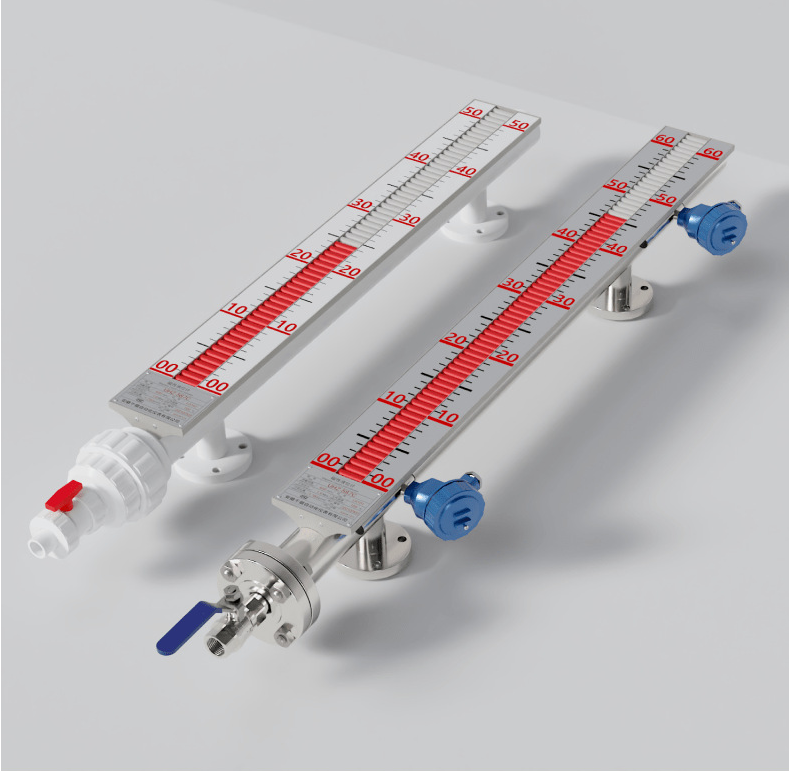

Magnetic flap level gauge is also called magnetic flap level gauge, magnetic column level gauge, magnetic float level gauge, etc. However, the parameters they need to know when ordering are certain. For example, corrosive media need anti-corrosion materials, and the anti-corrosion grade varies equally according to the corrosive grade of the media.

For another example, the special conditions of our own equipment determine the installation method of the magnetic flap level gauge, because some occasions are not suitable or are not suitable for a certain installation method at all.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist