BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Various process instruments in industrial production vary widely, but one thing remains the same, all instrumentation products are manufactured according to relevant scientific principles.

For example, electromagnetic flowmeters use the principle of electromagnetic action, and ultrasonic level meters are developed using the characteristics of ultrasonic waves. About the magnetic flap level gauge, as the name suggests, it uses the magnetic principle of metal to measure the liquid level.

Specifically, the structure principle of the magnetic flap liquid level gauge is developed based on the principle of buoyancy and magnetic coupling. When the liquid level in the measured container rises and falls, the magnetic float in the body tube of the liquid level gauge also rises and falls, and the float The permanent magnet inside is transmitted to the magnetic flip column indicator through magnetic coupling, which drives the red and white flip columns to flip 180°. When the liquid level drops, the flip column changes from red to white, and when the liquid level rises, the flip column changes from white to white. Red, the junction point of the red and white magnetic flap on the panel is the actual height of the internal liquid level.

We know that the magnetism of the magnetic flap level gauge is due to the fact that part of the tiny circuit inside the object is arranged in a certain direction for some reason (such as placing a non-magnetic iron block in a constant magnetic field for a long time), in one direction The total magnetic field strength is greater than in other directions, so it exhibits magnetism. High temperature will intensify the movement of the molecules inside the magnet, disrupt the arrangement of the internal molecules, and make the magnet lose its magnetism, which was discovered by Marie Curie, so the high temperature demagnetization point of the magnet is called the Curie temperature of the magnet.

This demagnetization point is a very important concept in the production and use of magnetic flaps. Because of the existence of the demagnetization point, for all magnetic materials, magnetism does not always exist, and it is closely related to temperature.

Generally, magnetic materials have a critical temperature Tc, above which, due to the violent thermal motion of atoms at high temperature, the arrangement of atomic magnetic moments is disordered. Below this temperature, the atomic magnetic moments are aligned, resulting in spontaneous magnetization, and the object becomes ferromagnetic.

If the temperature is too high, it will cause the magnetic force in the float or flip column to demagnetize. For users, when purchasing a product, it is necessary to provide a clear medium temperature to the instrument manufacturer to determine the high temperature float to be used.

How should we deal with the degaussing phenomenon of the magnetic flap level gauge, we can pay attention to the following aspects:

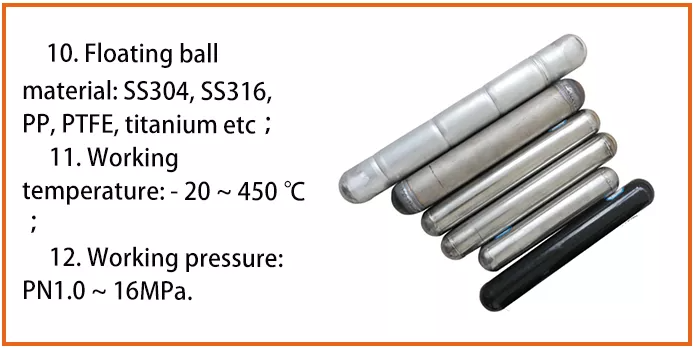

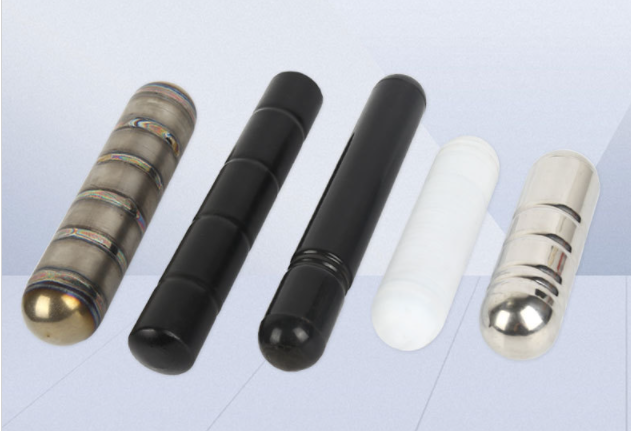

* First of all, the magnetic float of the high temperature magnetic flap level gauge will be demagnetized during use, which will cause the magnetic flap level gauge to fail. The operating temperature of high temperature magnetic flap level gauges (especially high temperature and high pressure magnetic flap level gauges) generally exceeds 180 degrees Celsius. Therefore, from the design point of view, it is necessary to select the appropriate hard magnetic material.

For example, choose a magnetic material whose Curie temperature is more than 20% higher than the operating temperature and ensure that the remanence exceeds the critical value after five years (the magnetic flap level gauge designed and produced by our company requires the coupling critical value to be around 1400 gauss);

Secondly. From the point of view of production, the following points should be paid attention to when processing the magnetic float:

1. During the production and processing stage of the product, it is necessary to take cooling measures during welding (argon arc welding) to prevent the temperature of the magnetic material of the magnetic float from exceeding the Curie temperature of the magnetic material.

2. Fill inert gas (such as argon) in the magnetic float in the measuring tube of the instrument;

Third, from the user's point of view, the following points need to be done:

1. Select the appropriate model when ordering, so that the operating temperature does not exceed the nominal temperature of the magnetic flap level gauge;

2. In use, it is necessary to observe the use of the level gauge at any time (whether it can be used normally), and to record the actual temperature of the medium (I have seen such a situation, the actual use temperature is often higher than the temperature on the parameter table, The person who designed the parameter table may have overlooked certain factors).

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist