BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

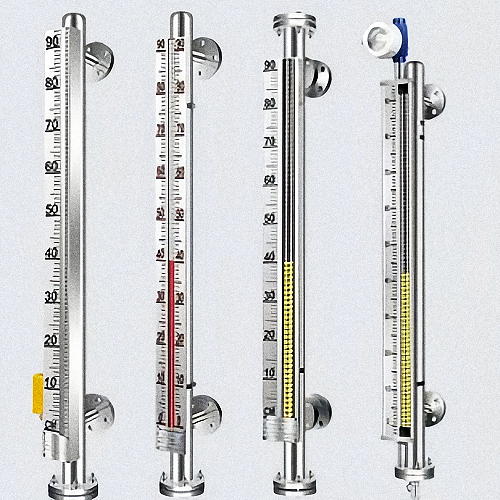

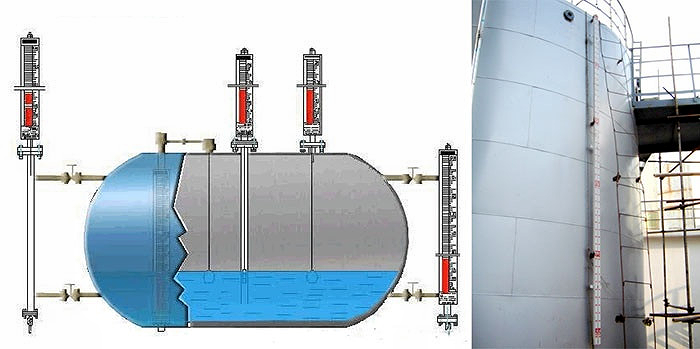

Instrumentation installed near the measured and controlled objects, generally outdoors, and no transmitter, no remote signal, this type of instrumentation is called in situ instrumentation, such as pressure gauges, glass plate level gauge, bimetal thermometer, etc. And the development of the use of liquid level gauge has been increasingly ignored. And the development of the use of remote instrumentation, so that the in situ level gauge is more and more neglected.SH 3136 "Liquefied hydrocarbon spherical storage tank safety design code" Article 5.3.1 requires that liquefied hydrocarbon spherical tanks should be equipped with remote and in situ level gauges, mandatory provisions in boldface; SH_T 3007-2014 "Petrochemical storage and transportation system tank design code" Article 6.3.1 provides that pressure storage tanks should be equipped with in situ level gauges.

What exactly is the role of in situ level meter? Imagine a scenario, the production of pressure storage tanks on two remote level meter, two level meter indication deviation is relatively large, need to calibrate the instrument, if there is no on-site in situ magnetic float level gauge as a reference, immediately silly eyes. This is perhaps the most direct role of in situ instrumentation.

General remote instrumentation calibration, is a two-point calibration, there is no in situ level meter, for pressure storage tanks simply can not be completed. Radar level meter or, magnetostrictive level meter also, need to be calibrated to use, atmospheric storage tanks, can check the ruler, pressure storage tanks and what to take as a reference.

In addition, if the power outage, no in situ liquid level meter, how to know the liquid level in the tank. For the management of standardized enterprises, the requirements of every two hours or so outside the operation of the inspection staff to use walkie-talkies and the main control room to check the level, the inspection staff to see the in situ level meter and the control room display data to check, not only to ensure that the level of precision, but also to the main control room to convey the information of the personal safety of the inspection staff. So critical and basic things, some places do not pay attention to.

For the "petrochemical tank automation system design specifications" SH_T 3184 in the volume greater than 100 cubic meters of the tank requirements for the configuration of the tank side indicator, but also "should", the recommended standards. In addition, for GB 17681 "flammable and explosive tank safety monitoring and control early warning system requirements," Article 5.5 requirements of a tank should be equipped with different measuring principles of the level meter. Technically no one absolute authority, do not engage in instrumentation maintenance, not squatting in the field all year round, simply can not experience process changes, environmental changes, equipment changes caused by a variety of instrumentation and equipment indication of deviation from the scene, paper. However, if the site is installed with in situ level meter, it is also considered to be different from other measurement principles of liquid level meter.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist