BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

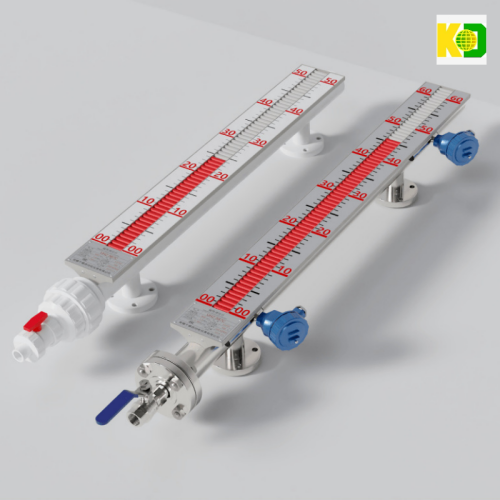

As a kind of common liquid level measuring instrument, magnetic flap level gauge, because the measuring tube body is connected with the measured vessel, directly contact with the medium, therefore, the material of the tube body is good or bad for the service life of the magnetic flap level gauge has a direct impact.If you use stainless steel directly to measure some corrosive media, it is easy to be corroded and leakage, resulting in production accidents. This is usually used in the tube lined with a layer of corrosion-resistant materials, will be measured and corrosive liquid isolation, to achieve anti-corrosion effect, so that the magnetic flip-flop level gauge can work stably and safely. However, due to the different corrosion strength of different media, the requirements for the lining material within the tube of the magnetic flap level gauge are also different.

1. Stainless steel lined with PP

Stainless steel lined PP magnetic flip-flop level meter is mainly used for the measurement of weak corrosive media such as weak acid and weak alkali, and is not suitable for use in strong corrosive liquids such as concentrated nitric acid, acid mixtures, chlorinated solvents, aliphatic and aromatic hydrocarbons, etc. The magnetic flip-flop level meter is mainly used for the measurement of weak corrosive media such as weak acid and weak alkali. Because PP pipe adopts steel lining structure, so its temperature and pressure resistance is higher compared with the use of polypropylene pipe (PP) or polyvinyl chloride pipe (PVC) alone.

2. stainless steel lined with PTFE

PTFE, also known as polytetrafluoroethylene, commonly known as "Plastic King", is one of the best materials for corrosion resistance in the world today. Stainless steel lined with PTFE production method is to push the PTFE pipe into the stainless steel body pipe, and then the two ends of the flange sealing surface and tightly attached to the flange. PTFE has a high degree of chemical stability and excellent chemical corrosion resistance, long-term use of the temperature of -200 ~ +250 ° C, more used as a corrosion-resistant lining materials. Using stainless steel lining of the magnetic flap level meter, mainly for strong acid, alkali, strong oxidizing agents and other corrosive media, but can not be used in liquid chlorine, liquid bromine and other highly permeable liquid media.

3.Stainless steel lined with FEP

FEP, that is, polyperfluoroethylene propylene, its anti-corrosion properties similar to PTFE, with a high degree of chemical stability and chemical corrosion resistance, the use of its temperature is slightly lower than PTFE, the maximum use temperature of 200 ℃, but also more for the lining of corrosion-resistant materials, but the price is higher than PTFE.

Similar to the lining method with PTFE lining, stainless steel lining FEP will be FEP pipe pushed into the stainless steel body pipe, flanging at both ends and tightly attached to the flange sealing surface. Due to the difference between FEP and PTFE forming process, it can be used not only in strong corrosive media such as strong acids, strong alkalis, strong oxidizers, but also in liquid chlorine, liquid bromine and other highly permeable liquids for a wider range of applications.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist