BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Level switch types are diverse, such as float level switch, tuning fork level switch, etc., that we need to understand their respective advantages and disadvantages before choosing. Today Kaidi Sensors will give you an introduction.

First, tuning fork level switch

Advantages:

1, vibration tuning fork level switch can be truly free from the flow, bubbles, turbulence, foam, vibration, solid content, staining, liquid characteristics and product changes.

2、No calibration required, easy to install.

3、No moving parts or gaps truly maintenance-free.

4、Powerful self-checking and diagnostic function ensures high reliability of high and low level measurement.

Disadvantages: tuning fork switch is not suitable for very viscous media. The material buildup between the forks that cause the forks to be connected together will interfere with the level detection.

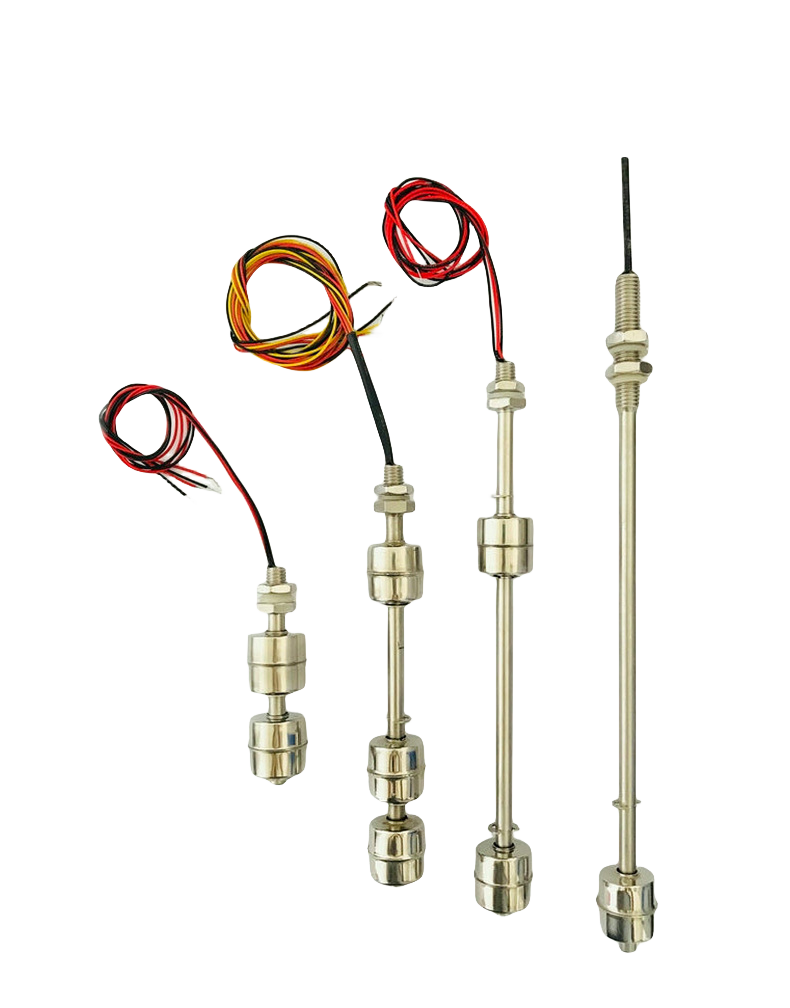

Second, float level switch

Advantages:

1, it is a simple structure, easy to use, safe and reliable level controller.

2, it is faster than the general mechanical switch, long working life; compared with the electronic switch, it is characterized by strong load impact resistance.

3、Float level switch adopts straight float to drive the magnet inside the switch, and the simple lever of float switch makes the switch act instantly. The float cantilever angle limit design prevents the float from being vertical.

4、Widely used in shipbuilding, paper making, printing, generator equipment, petrochemical industry, food industry, electrician, dye industry, hydraulic machinery and so on.

Disadvantages:

1, float switch is a simple passive device, and does not have a self-checking function, so it is recommended to carry out regular inspection and maintenance.

2, Float or float level meters are moving parts, so they can get dirty when used in thicker or viscous liquids.

3、Measurement accuracy is poor, viscosity <0.8mpa*s can not work.

4、Pressure, density and dielectric constant are required in the container, and installation requires shutdown, tank cleaning, hole opening and fire.

Third, the advantages of radar level meter:

Radar level meter, also known as high-frequency radar level meter, contact radar level meter, as a kind of non-contact sensor, the main working principle is to detect the microwave information reflected from the surface of the liquid, and then calculate the position of the surface of the object.

When the antenna of the radar level meter transmits electromagnetic wave, the electromagnetic wave is reflected by the liquid surface and then received by the antenna, and the time from transmitting to receiving the electromagnetic wave is proportional to the distance between the electromagnetic wave and the liquid surface. Based on the principle of time dilation technique, the time interval between the transmitting pulse and the receiving pulse is calculated, and thus the distance between the antenna and the surface of the measured medium is calculated.

From the above principle of radar level meter, it can be seen that the main advantage of radar level meter is its fast speed, non-contact, all-weather online real-time continuous detection.

Fourth, radio frequency conductivity level switch

Advantages:

1, versatility: can measure liquid level and material level, can meet the measurement requirements of different temperatures, pressures, media, and can be applied to corrosion, impact and other harsh occasions.

2、Anti-hanging material: unique circuit design and sensor structure, so that its measurement can not be affected by the sensor hanging material, no need for regular cleaning, to avoid mismeasurement.

3、Maintenance-free:Measuring process has no moving parts, there is no mechanical parts damage, no maintenance.

4、Anti-interference: contact measurement, anti-interference ability, can overcome the steam, foam and stirring on the measurement of the impact.

5、Accurate and reliable: the measurement volume is diversified, making the measurement more accurate, Zeliang is not affected by environmental changes, high stability, long service life.

6、Applicable scope: chemical industry, oilfield, water and sewage treatment, papermaking, pharmaceutical, power plant, metallurgy, cement, grain and other industries.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist