BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Application of Ultrasonic Level meter in Crude Oil Storage Tanks: Technical Adaptation, Solutions, and Practices

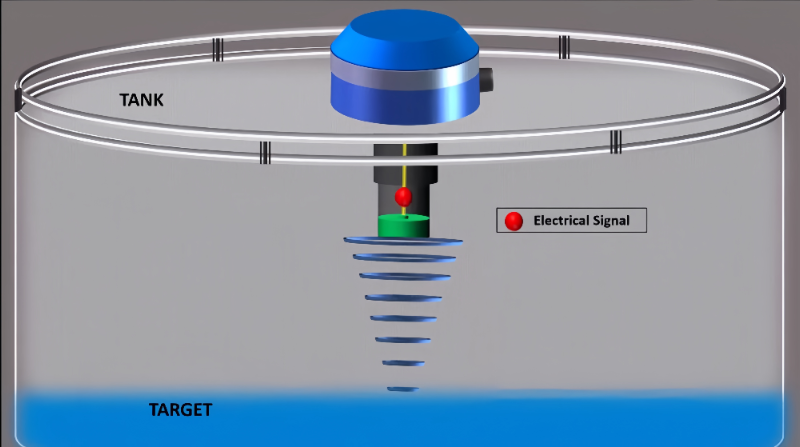

As critical storage facilities in the petrochemical industry, crude oil storage tanks require precise level monitoring to ensure operational safety, inventory management, and cost control. Conventional level measurement devices, such as float-type and servo-driven instruments, often encounter challenges including frequent maintenance, accuracy degradation, and safety risks—particularly under conditions characterized by high viscosity, volatility, impurity content, and potential flammability or explosiveness of crude oil. In contrast, ultrasonic level meter have emerged as a mainstream solution for level monitoring in crude oil storage tanks due to their non-contact measurement principle, strong anti-interference capability, and ease of installation. Their application necessitates tailored technical adaptations and systematic solution design aligned with specific operational conditions.https://www.kaidi86.com/level-ultrasonic.html

I. Operational Challenges of Crude Oil Storage Tanks: Ultrasonic Level Meter Compatibility Requirements

The specialized operating environment of crude oil storage tanks imposes stringent requirements on liquid level measurement instrumentation, presenting critical challenges that must be addressed prior to deploying ultrasonic level meter;

Complex medium characteristics: The high viscosity of crude oil (typically 50–1000 mPa·s), its adhesive properties, and the presence of solid impurities such as sand particles and waxes can cause conventional contact-based measurement devices to fail due to component adhesion and clogging;

Volatility and Flammable/Explosive Hazards: The light components of crude oil are highly volatile, forming combustible vapor-air mixtures (with typical explosion limits ranging from 1.1% to 8.7%). Equipment must possess explosion-proof certification to prevent electrical sparks from triggering safety incidents;

Multiple environmental interferences: Oil storage tanks are predominantly installed outdoors in exposed settings, subject to natural disturbances such as diurnal temperature variations ranging from -30°C to 60°C, wind, rain, and dust. Additionally, the crude oil surface is prone to foam formation and wax deposition, which impair signal reflection;

High precision and stability requirements: Large crude oil storage tanks can have capacities ranging from 10,000 to 100,000 m³. Liquid level measurement errors must be controlled within ±0.5% to ensure accurate inventory accounting and prevent economic losses;

Low maintenance demands: Oil storage tanks are often installed at elevated heights (10–30 meters). Conventional equipment requires periodic climbing for inspection and maintenance, which not only reduces efficiency but also poses safety risks associated with working at height.

To address these challenges, ultrasonic level meter offer a precisely tailored solution through technical features such as non-contact measurement (avoiding media adhesion), explosion-proof structural design (suitable for flammable and explosive environments), and environmental compensation algorithms (resisting temperature and humidity interference).

II. Core Application Advantages of Ultrasonic Level meter in Crude Oil Storage Tanks

Compared with traditional level measurement equipment, ultrasonic level meter demonstrate five irreplaceable advantages in crude oil storage tank applications:

1. Non-contact measurement: Complete elimination of media interference

Ultrasonic level meter employ high-frequency acoustic waves (20-40 kHz) emitted from a transducer to perform liquid level measurements. As the transducer operates without direct contact with the crude oil surface, it entirely eliminates issues such as probe clogging and measurement drift caused by adhesion of high-viscosity crude oil. Field data from an oilfield demonstrate that after adopting ultrasonic level meter, equipment failures due to medium adhesion were reduced from 3–5 occurrences per month to zero annually, resulting in a substantial decrease in maintenance frequency.

2. Explosion-Proof and Corrosion-Resistant Design: Adaptation to High-Ranger Environments

Explosion-Proof Performance: Mainstream industrial-grade ultrasonic level transmitters are certified with Ex d IIC T6 explosion-proof ratings (premium models can achieve Ex ia IIC T4). Both the probe and housing are integrally molded from 316L stainless steel, with a sealing class of IP68, ensuring safe operation in environments with excessive oil and gas concentrations and eliminating the risk of electrical sparks.

Corrosion Resistance: To address corrosive components such as sulfides and organic acids present in crude oil, the probe surface can be coated with polytetrafluoroethylene (PTFE) or aluminum nitride ceramic. The corrosion resistance complies with ISO 10289 standards, offering a service life of 5–8 years, which is more than three times that of ordinary carbon steel probes.

3. Anti-interference Algorithm: Ensuring Measurement Accuracy in Complex Working Conditions

Common interferences in crude oil storage tanks such as foam, wax formation, and temperature fluctuations can be effectively addressed by the dedicated algorithms of ultrasonic level meter:

Foam Filtering Algorithm: By identifying the characteristic differences between "crude oil liquid surface echo" (stable amplitude, steep rising edge) and "foam echo" (weak amplitude, long duration), the algorithm automatically filters out foam interference. Even when the foam thickness reaches 50 cm, it can still accurately capture the true liquid level.

Temperature Compensation Technology: Equipped with a high-precision PT100 platinum resistance (accuracy ±0.05℃), it continuously collects the temperature inside the tank and dynamically corrects the sound speed through the formula v = 331.4×√(1 + T/273.15). Within a temperature range of -30℃ to 60℃, the measurement error can be controlled within ±0.2% FS.

Wax Formation Adaptive Adjustment: If the signal is weakened due to wax formation on the probe surface caused by crude oil evaporation, the device will automatically increase the transmission power (from 5W to 15W) to ensure that the sound wave penetrates the wax layer and maintains measurement stability. A case study in a refinery shows that this feature has increased the measurement efficiency under wax formation conditions from 75% to 99.8%.

4. Remote Monitoring and Intelligent Capabilities: Reduction of Management Costs

Modern ultrasonic level transmitters support communication protocols such as RS485/Modbus and 4G/NB-IoT, enabling real-time transmission of level data to central control systems (e.g., SCADA, DCS) for remote monitoring and data storage. Personnel can access information on tank levels, temperature, and historical trends via computers or mobile devices without the need for on-site inspections. Following implementation at an oil depot, manual inspection costs were reduced by 60%, and data recording accuracy improved from 85% to 100%.

5. Ease of Installation: Compatibility with Diverse Tank Types

The ultrasonic level meter requires no structural modification to storage tanks for installation. It only necessitates a reserved DN50-DN100 mounting interface on the tank roof, secured via flange or threaded connection. The installation time for a single unit does not exceed two hours. Compatible with vertical cylindrical tanks, horizontal tanks, and spherical tanks alike, the device adapts to various tank configurations through probe angle adjustment (certain models support 0-15° tilt adaptation), offering significantly greater flexibility compared to traditional servo level meter.

III. Key Technical Solutions for Ultrasonic Level Transmitters in Crude Oil Storage Tanks

To ensure stable operation in crude oil storage tanks, ultrasonic level measurement systems require a comprehensive technical framework spanning three critical dimensions: hardware selection, algorithmic optimization, and installation commissioning:

1. Hardware Selection: Matching Crude Oil Storage Tank Conditions

Range and Accuracy Specification: Select models with an empty measurement range of 35-50 meters (providing 20% redundancy to mitigate signal attenuation) based on typical tank heights (10-30 meters). Accuracy must reach ±0.3% FS with a resolution of 0.1mm to meet inventory measurement requirements.

Probe Material Selection: Prioritize probes with "316L stainless steel housing + PTFE coating" for corrosion and wax deposition resistance. In environments with extremely high oil vapor concentration, explosion-proof probes (Ex d IIC T6) shall be adopted to ensure operational safety.

Power Supply and Communication Configuration: Utilize 24V DC intrinsically safe power sources (to eliminate high-voltage risks). Modbus-RTU is the preferred communication protocol due to its strong anti-interference capability and transmission distance of up to 1000 meters. For remote wellhead storage tanks, NB-IoT modules may be integrated to enable wireless data transmission.

2. Algorithm Optimization: Targeted Solutions for Crude Oil Storage Tank Interference

Multi-echo Identification Algorithm: Given that the inner wall of crude oil storage tanks often contains protrusions and support structures that generate false echoes, a dual-condition algorithm combining "echo amplitude thresholding and distance filtering" is employed. This method retains only the liquid level echoes (within the tank height range) while eliminating spurious signals from internal structures;

Dynamic Power Adjustment: The transmission power is automatically regulated according to seasonal variations. During winter (low temperatures increase wax deposition risk), power is elevated to 15–20W, while in summer (high temperatures intensify Vaporization of oil and gas), it is reduced to 8–12W. This balances measurement stability with energy consumption;

Data Smoothing Processing: To address liquid level fluctuations during feeding or discharging operations, a moving average algorithm (averaging 5 data points within a 10-second window) is applied. This prevents abrupt level data jumps caused by transient disturbances and ensures stable display readings in the central control system.

3. Installation and Commissioning: Precision Depends on Details

Location Selection: The probe shall be mounted atop the storage tank, away from the feed inlet and agitator (maintaining a distance from the tank wall ≥ 1/10 of the probe’s range to avoid interference from wall reflections). For tanks with a diameter ≥ 20 meters, it is recommended to install two sensors for redundant measurement to enhance system reliability;

Waveguide Assistance (Optional): If persistent foam thickness inside the tank exceeds 1 meter, a metal waveguide (with an inner diameter of 100–150 mm, constructed of 316L stainless steel) may be installed below the probe. Acoustic waves propagate along the waveguide, effectively eliminating foam interference. This configuration supports a measurement range of up to 30 meters without compromising accuracy;

Field Calibration: Post-installation accuracy must be verified using the “Known Height Calibration Method.” A standard reference object is suspended at a known height (e.g., 10 meters) inside the tank. The sensor’s measured value is compared against the actual value. If the error exceeds ±0.5%, compensation parameters shall be adjusted via the central control system to ensure calibrated accuracy meets specifications.

IV. Practical Application Case: Implementation Effectiveness of Ultrasonic Level Transmitters in Crude Oil Storage Tanks

Case 1: Monitoring of a 10,000m³ Vertical Crude Oil Storage Tank in an Oilfield

Operational Challenges: The tank height is 18 meters, with crude oil viscosity of 500 mPa·s. Internal temperatures range from -25°C to 10°C in winter and 30°C to 55°C in summer. Traditional float-level meters require bi-monthly disassembly and inspection due to crude oil adhesion, with a measurement error of ±1.2%, failing to meet inventory accounting requirements;

Solution: An ultrasonic level transmitter with a 30-meter no-load range and Ex d IIC T6 explosion-proof rating was selected. The probe is constructed with 316L stainless steel and a PTFE coating, integrated with temperature compensation algorithms and multi-echo recognition algorithms. Communication is established via Modbus-RTU protocol connected to the oilfield’s SCADA system;

Application Results:

Measurement accuracy stabilized at ±0.25% FS, with an error of only ±45 mm over the 18-meter range, meeting the ±0.5% requirement for inventory accounting.

Maintenance-free operation for 18 months, with no failures due to medium adhesion or wax deposition, reducing maintenance costs by 90%.

No data drift under temperature fluctuations; normal operation maintained at -25°C in winter, with a data transmission success rate of 99.9%.

Case 2: Monitoring of a 5,000m³ Horizontal Crude Oil Storage Tank in a Refinery

Operational Challenges: The horizontal tank measures 20 meters in length and 4.5 meters in diameter, equipped with an agitator (rotating at 60 rpm) that induces vortices and foam on the liquid surface. Traditional servo-level meter require replacement every six months due to mechanical wear, with measurement errors reaching ±0.8% caused by vortices.

Solution: Two ultrasonic level transmitters with a 20-meter no-load range were installed redundantly at both ends of the tank. Foam filtration algorithms and dynamic power adjustment functions were activated. Data is transmitted via a 4G module to the refinery’s DCS system, enabling dual-sensor data comparison and anomaly alarms.

Application Results:

Deviation between dual-sensor measurements ≤ ±20 mm, effectively eliminating vortex interference, with measurement accuracy reaching ±0.3%.

No mechanical wear on equipment, extending service life to 6 years and reducing replacement costs by 80%.

Automatic switching to the backup sensor in case of single-sensor failure ensures uninterrupted monitoring and significantly enhances safety redundancy.

V. Application Considerations and Future Trends

1. Application Considerations

Regular Probe Cleaning: Although ultrasonic level meters employ non-contact measurement, probe surfaces may accumulate crude oil volatiles or dust over prolonged use. It is recommended to clean the probe surface with alcohol quarterly to prevent signal attenuation;

Avoid Strong Electromagnetic Interference: Installation sites should maintain a minimum distance of 5 meters from high-power equipment such as motors or transformers near storage tanks. If unavoidable, shielded cables (e.g., RVVP shielded cables) must be used for signal transmission to mitigate electromagnetic interference;

Lightning Protection: Outdoor storage tanks require lightning protection devices (e.g., lightning rods or surge protectors) for ultrasonic level meters to prevent lightning-induced damage. For instance, a previous incident at an oil field resulted in the failure of three sensors due to lightning strikes, causing direct economic losses, attributed to the absence of lightning protection measures.

2. Future Development Trends

AI-Powered Diagnostics: Machine learning algorithms will analyze level data trends to autonomously identify anomalies such as "signal attenuation due to wax deposition" or "probe malfunction," issuing maintenance alerts up to 30 days in advance to further reduce failure rates;

Multi-Parameter Integration: Future ultrasonic level meters will integrate functions such as oil-gas concentration detection and pressure measurement, enabling synchronous monitoring of "level-temperature-concentration-pressure" parameters. This will provide comprehensive data support for enhanced safety management of crude oil storage tanks;

Low-Power Design: For remote unmanned storage tanks without power supply, solar-powered ultrasonic level meters with ultra-low standby power consumption (≤10mA) will be developed. Combined with LoRa wireless communication, this will facilitate long-term unattended monitoring.

Conclusion

Ultrasonic level meters, with their non-contact measurement, explosion-proof and corrosion-resistant design, and anti-interference algorithms, are ideally suited for the complex operational conditions of crude oil storage tanks. They effectively address the limitations of traditional equipment, such as frequent maintenance, inadequate accuracy, and safety risks. In practical applications, optimal performance—including high accuracy, stability, and low maintenance—can be achieved through hardware selection and algorithm optimization tailored to tank height, medium characteristics, and environmental conditions, along with meticulous attention to installation and commissioning details. With advancements in smart technologies, ultrasonic level meters will evolve toward multi-parameter integration, self-diagnosis, and low power consumption, solidifying their role as core devices for level monitoring in crude oil storage tanks and providing robust technical support for safety and efficiency in the petrochemical industry.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist