BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

In the grain processing and feed production industries, storage management of finished product silos is a critical factor in ensuring production continuity and quality stability. Accurate knowledge of feed volume, mass, and distribution within silos is vital for inventory control, production planning, and cost management. However, traditional measurement methods often suffer from low efficiency, significant errors, and poor safety. With technological advancements, intelligent measurement solutions based on radar scanning are increasingly being adopted in this field. Among these, the 3DPro2300Easy radar scanning robot introduced by Guangdong Kaidi Energy Technology Co., Ltd. leverages advanced three-dimensional radar scanning technology to provide a novel intelligent solution for feed finished product silo storage management. This innovation effectively enables precise sensing and efficient management of inventory data.

Traditional measurement methods face multiple challenges.

Storage measurement in finished feed silos has long faced numerous challenges:

● Insufficient accuracy: Manual tape measurements or weight-based methods are prone to errors due to material pile configurations and human factors;

● High safety risks: Personnel must climb silo roofs or enter confined spaces, exposing them to fall hazards and dust inhalation risks;

● Severe environmental interference: Dust-filled silo interiors disrupt optical equipment, causing measurement interruptions or data distortion;

● Structural interference: Screw conveyors occupy internal space, making traditional methods ineffective for volume calculation. These pain points not only increase management costs but also pose safety hazards for enterprises.

3D Radar Scanning Robot: Intelligent Measurement, Precision Without Worry

For the specific operating conditions of finished feed storage silos, the 3DPro2300Easy radar scanning robot demonstrates significant technical advantages:

True 3D modeling with comprehensive and precise data

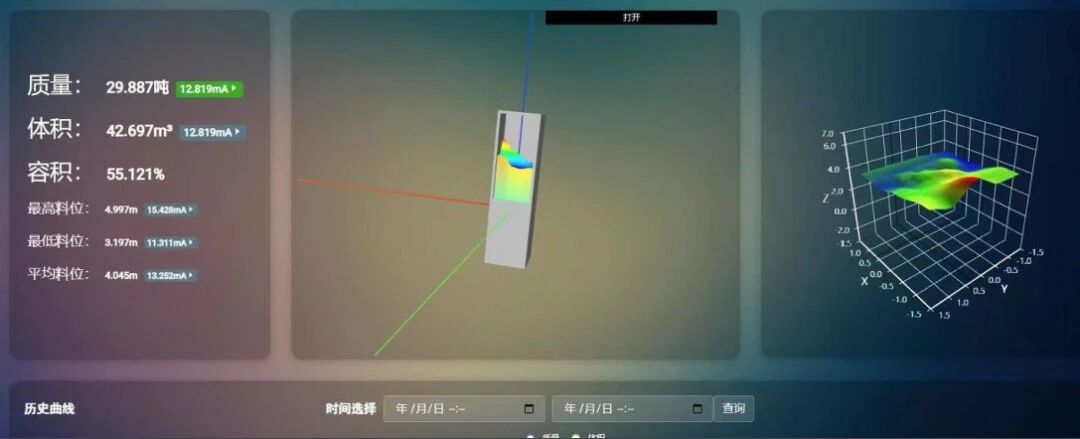

The device employs high-frequency radar rotation scanning to efficiently collect thousands of point cloud data points from the feed surface within the silo, generating a high-precision 3D model. Utilizing advanced algorithms, the system automatically identifies and excludes interference from fixed structures such as screw feeders, accurately calculating the actual volume and mass of the feed. Users can clearly visualize material distribution patterns through an intuitive interface, effectively preventing issues like overload or empty silos.

Highly resistant to dust, stable and reliable

Due to the strong penetrating power of radar waves, the equipment can operate stably even in high-dust environments without interference from dust, ensuring data continuity and accuracy.

Unmanned operation, safe and efficient

The 3D radar scanning robot can be permanently installed on warehouse roofs to perform fully automated periodic scans without manual intervention, effectively reducing risks associated with working at heights. Measurement data is synchronized in real time to the management backend, enabling enterprises to achieve dynamic inventory monitoring and lean management.

Comprehensive functionality, one-stop solution for all your warehousing needs

The system not only provides volume, mass, and capacity data but also supports multi-bin comparisons, trend analysis, and report generation, offering reliable support for enterprise production planning and logistics scheduling.

Guangdong Kaidi Energy Technology Co., Ltd.'s 3DPro2300Easy radar scanning robot has become the preferred solution in feed storage measurement due to its exceptional environmental adaptability, precise data output, and highly automated operation. It not only enhances enterprise management efficiency and reduces operational risks but also provides a practical pathway for the industry's intelligent upgrade.

The company specializes in automated measurement and control products such as radar level gauges and 3D vision imaging systems, addressing diverse industrial measurement requirements. Leveraging innovative technologies from its R&D center, it delivers customized solutions tailored to client needs, positioning itself as a technological innovator in China's industrial automation measurement and control sector.

Its products and solutions are extensively deployed across mining, coal, oil and gas, power generation, metallurgy, chemical processing, building materials, grain storage, animal feed, food and beverage, pharmaceuticals, environmental protection, and cement industries.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist