BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

A level meter is an instrument that measures the height of a liquid medium in a container. Liquid level meter is also called liquid level transmitter. Liquid level meter is suitable for liquid level measurement of various media in petrochemical, metallurgy, electric power, pharmaceutical, water supply and drainage, environmental protection and other systems and industries. The compact structure, simple adjustment and flexible installation provide convenience for users to use easily.4~20mA, 0~5v, 0~10mA, etc.Known as the standard signal.The output method is selected by the user as desired.

A level meter is an instrument that detects changes in the height of solid material (solid or liquid level) in a vessel in real time. Level meter is also known as material level transmitter, material level controller, material level meter, material level gauge and so on. The level meter is mainly used for measuring the surface position of solid lumps or powder in the storage silo, in order to understand the amount of material stored in the storage silo; thermal power plants need to detect the raw coal hopper and pulverized coal silo in the position of coal lumps and pulverized coal, and so on.

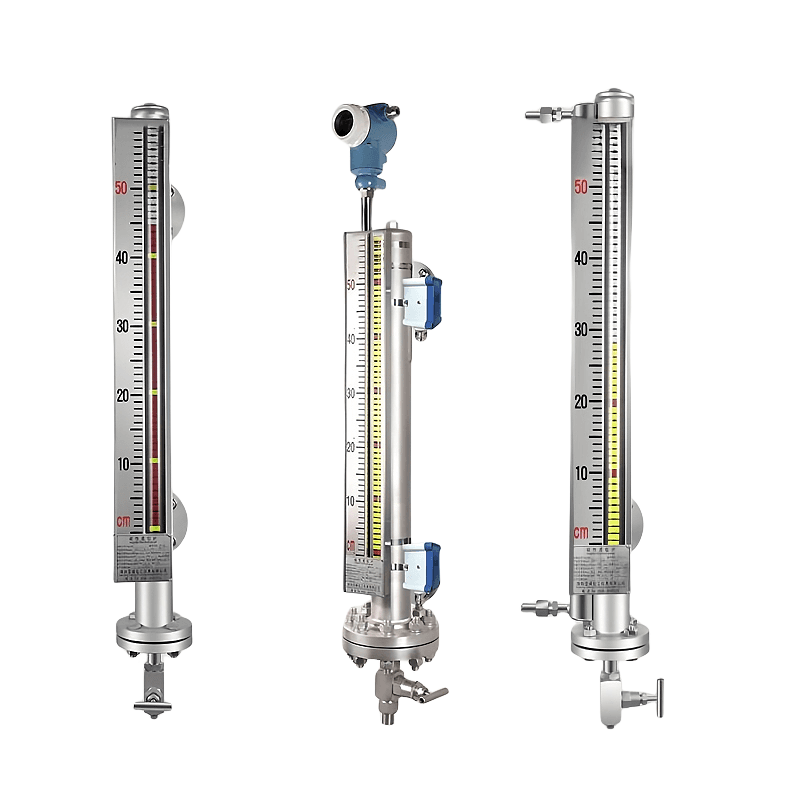

Liquid level meter is one kind of level meter, the level meter can measure the solid material, also can measure the liquid material. Liquid level meter is a kind of instrumentation specializing in measuring liquid media. The types of liquid level meter are tuning fork (tuning fork switch is based on the tuning fork resonance principle. Its core component is a pair of well-designed tuning forks, through a pair of piezoelectric crystals mounted on the tuning fork base so that the tuning fork to a specific frequency for free vibration, its vibration pattern is similar to the sound fluctuations generated by striking a tuning fork in the air. When the tuning fork is in contact with the measured medium, the density and damping properties of the medium have an effect on the vibration of the tuning fork. This effect causes a change in the frequency, amplitude or phase of the tuning fork's vibration. The sensor immediately captures this change, which is detected, processed and converted into a switching signal by an intelligent circuit.) Vibrating, magnetic float, pressure, ultrasonic, sonar wave, magnetic flap ( The structure of the magnetic flap level meter consists of float (main tube), magnetic float, magnetic flap (magnetic flip column), indicator, drain valve, connecting flange and so on) radar and so on.

In the field of industrial automation, more and more instruments are used, such as liquid level meter, level meter and other instruments have covered the industry, agriculture, transportation, science and technology, environmental protection, national defense, culture, education and health, people's life and other aspects. Since entering the 21st century, the instrumentation industry in promoting the global development of strategic new industries, industrial transformation and upgrading, promoting modern national defense construction, safeguard and improve people's living standards to play a more and more obvious role, the industry scale is also constantly improving.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist