BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

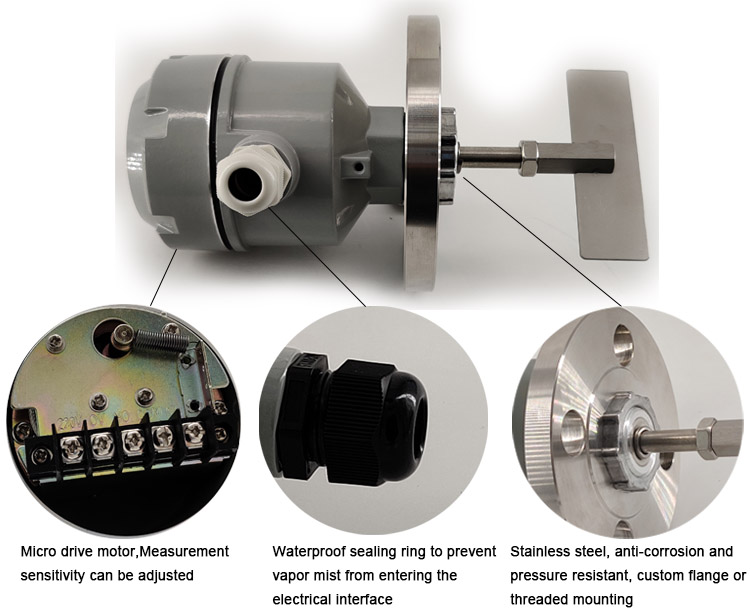

It is used in metallurgy, chemical industry, petroleum, electric power, food, papermaking, coal, building materials, medicine and other fields of material level monitoring and control, detection and control of powder, granular, lumpy materials in open silo and closed silo, mechanical instrumentation, simple structure, temperature resistance, no complicated electrical wiring, accurate detection, reliable control of dust, shock resistance for long-term operation, stable and reliable.

Common faults of resistive level switch.

1、Motor failure

The main performance is the spindle does not turn or spindle idle motor noise. The motor is an important part of the resistance level switch, its importance to the resistance level switch is as important as the heart for people. When the motor fails, the solution is to replace the motor with a new one. Therefore, the reliability of the motor is directly related to the rotary level switch. When choosing a rotary level switch, it is important to choose a motor and core material with excellent configuration, reliability and long service life.

2、Spindle jamming

The spindle and the spindle parts with unqualified size will lead to spindle jam. In the spindle jam, there will be spindle idle accompanied by strange noise, or tension spring due to resistance stretching, which can easily lead to false alarms and even reduce the service life of the product. To solve the problem of blocking the spindle of the rotary paddle level switch, on the one hand, the processing size of the parts should be qualified, and the raw materials should be strictly controlled; on the other hand, the assembly should be in strict accordance with the requirements of the process documents to ensure adequate lubrication of the parts.

3、Microswitch failure

There are two micro-switches in the resistive level switch, one is normally open and one is normally closed. Micro switch failure will lead to the blade touch the material after the motor does not stop turning or switching signal output error. If the micro switch fails, it can only be replaced by a new micro switch. As the micro switch is also a very important part of the rotary paddle type level switch.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist