BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

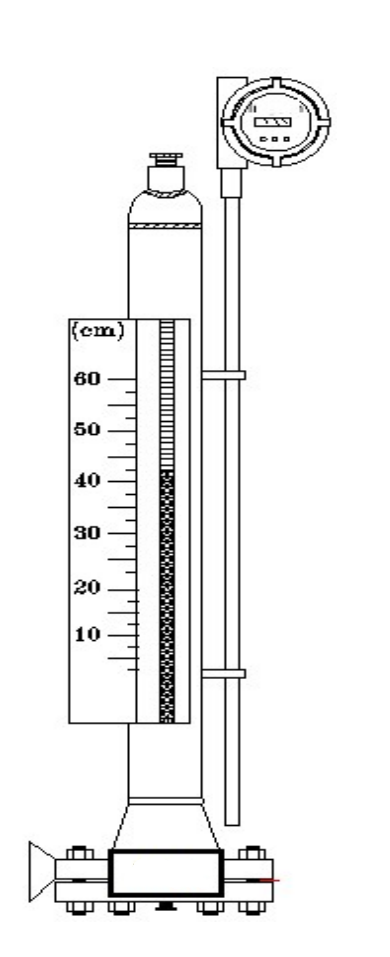

Accurate Measurement - Magnetostrictive Level GaugeIn the field of industrial automation, accurate level measurement is the core of production safety and efficiency.UCZ Magnetostrictive Level Gauge redefines the standard of liquid level monitoring with cutting-edge technology, providing reliable solutions for tanks, reactors and other scenarios.

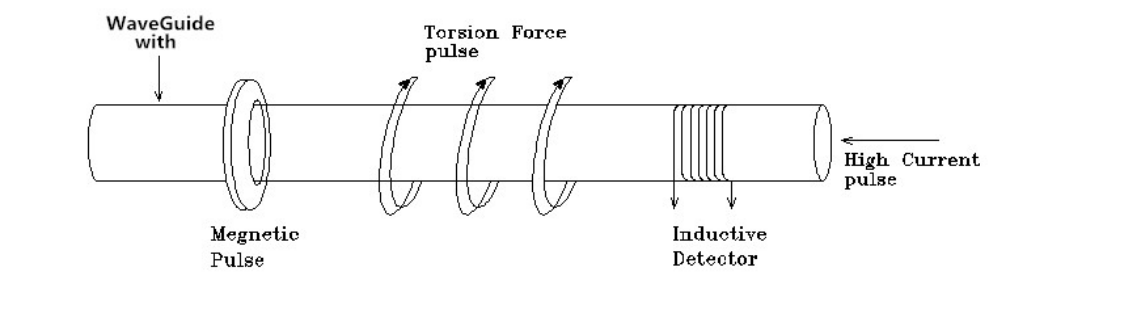

Working Principle

Magnetostrictive Level Transmitter is designed using a physical phenomenon - the magnetostrictive principle.

The working principle is as follows: a fine magnetostrictive wire is installed inside a non-magnetic sensing tube, and a pressure

magnetic sensor is connected to one end of the wire. The pressure magnetic sensor sends out 10 current pulses to the magnetostrictive wire every second and times them, which are transmitted along the wire and down to

, generating a downward-moving toroidal magnetic field, which interacts with the magnetic field of the magnetic float, and generates a torsional stress wave on the magnetostrictive wire. The magnetic field interacts with the magnetic field of the magnetic float, generating a

torsional stress wave on the magnetostrictive line, which travels up and down the magnetostrictive line at a known speed from the float's position until the piezomagnetic transducer receives a

signal of this torsional stress wave. The time interval between the starting current pulse and the returning torsional stress wave can be known through the timing circuit, and the position of the float can be judged according to the size of the time interval

. Since the float always floats on the liquid surface, the position of the liquid surface can be judged accurately.

Core Advantages

1.High precision measurement: adopting magnetostrictive principle, the resolution reaches ±0.5mm, real-time feedback of liquid level, interface and temperature data to meet the needs of severe working conditions.

2. Strong environmental adaptability: fully enclosed structure design, resistant to extreme temperatures from -196℃C to +200℃C and 40MPa high pressure, fearless of corrosive media and complex working conditions.

3. Zero maintenance: no mechanical moving parts, anti-vibration, calibration-free service life of more than 10 years, significantly reducing operation and maintenance costs.

Application Scenario:

Petrochemical, LNG storage and transportation, pharmaceutical, food, water treatment and other industries, suitable for all kinds of liquids, slurries and interface measurement. Magnetostrictive level gauge, military grade quality escort industrial safety, intelligent output 4-20mA/RS485 signal, seamless connection to DCS system, help enterprises to achieve digital upgrade.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist