BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Introduction

Magnetic Flip Flop Level Gauges (Magnetic Level Indicators) have become an indispensable tool in many industries for accurately measuring liquid levels in tanks and vessels. Their reliable performance and extremely low maintenance requirements make them ideal for use in challenging environments. In this article, we will discuss the importance, working principle, and advantages of magnetic flip-plate level indicators, and how kaidi magnetic flip-plate level indicators meet the high demands of industrial liquid level measurement.

What is a Magnetic Level Gauge?

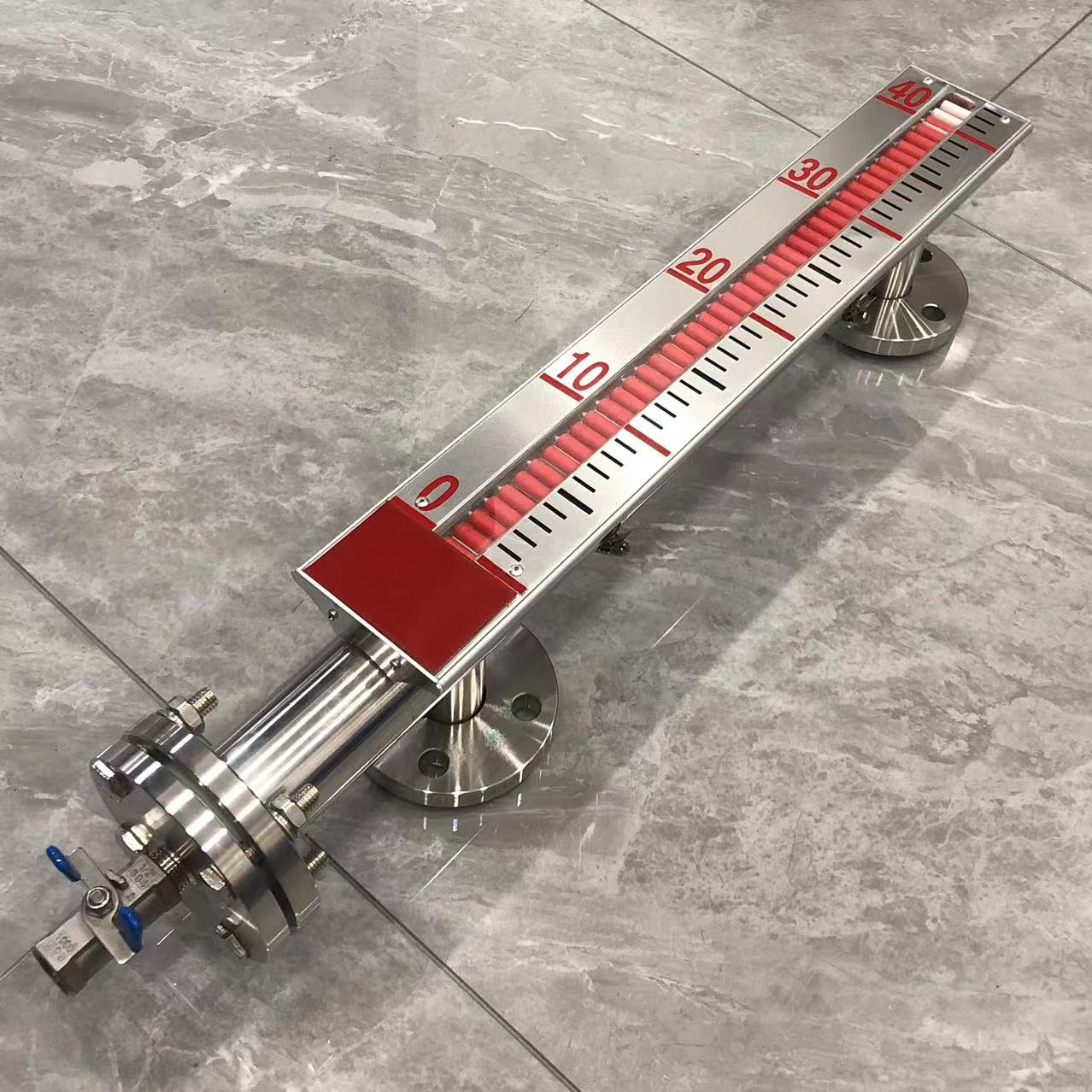

A Magnetic Flap Level Gauge, also commonly referred to as a Magnetic Level Indicator (MLI), is a device used to visually display the level of liquid in a storage tank or vessel. Unlike traditional sight glass level gauges, magnetic flip flop level gauges utilize a magnetic float system where the float is enclosed in a sealed chamber, ensuring that the liquid never comes into contact with the external environment. These devices provide a safe, accurate and maintenance-free solution for level measurement in a variety of industrial processes.

Operating Principle of Magnetic Flap Level Gauges

The core operating principle of a magnetic flap level gauge is based on magnetic coupling. The device is equipped with a float containing a magnetic element, which moves up and down as the liquid level rises and falls. The movement of the float drives the flap in the external indicator to flip through the magnetic force, so as to visually display the current liquid level height.

Compared with the traditional sight glass level meter, the magnetic flip-flop level meter adopts the fully enclosed design, the measuring medium is completely isolated inside the cavity, which completely solves the problem of leakage and pollution. This unique structure makes it especially suitable for measuring corrosive, high temperature or high pressure media.

Unlike sight glass level gauges, which are prone to breakage and require frequent maintenance, magnetic flap level gauges increase safety by preventing the liquid from being exposed to the external environment. Additionally, flip-flop level gauges are suitable for measuring corrosive, high-temperature, or high-pressure liquids, environments that are often difficult for conventional level measurement tools to handle.

Why choose kaidi magnetic flap level meter?

The kaidi Magnetic Flip Flop Level Gauge takes magnetic level measurement technology to a new level. Designed for a wide range of applications, the instruments provide high visibility level indication and have a rugged design to ensure long term reliability. kaidi Magnetic Flip Flop Level Gauges key features include:

•High visibility: the magnetic indicator provides a clear, easy-to-read indication of liquid level from a distance for real-time monitoring.

•Maintenance-free operation: Thanks to its simple and durable design, the kaidi magnetic flap level gauge requires less maintenance than other liquid level measurement solutions such as traditional sight glass level gauges.

•Wide range of applications: Whether in the chemical, oil and gas, or food and beverage industries, the instrument is able to meet the challenges of corrosive liquids and extreme temperatures without compromising on measurement accuracy.

Advantage

1. Non-Contact Measurement: A key advantage of magnetic level indicators is the ability to measure level without direct contact with the liquid. This is particularly important when measuring hazardous, corrosive or high temperature liquids and avoids the safety risks that can be associated with other measurement techniques.

2. Durability: The sealing system of a magnetic flap level gauge ensures that it is much less susceptible to wear and tear than traditional sight glass level gauges, which are prone to failure due to rupture or damage. This makes the flipper level gauge ideal for use in harsh environments and provides longer stable performance.

3. Low Maintenance Requirements: Since there are no moving parts exposed to the liquid, magnetic flip chart level gauges experience less wear and tear, which reduces the need for regular maintenance, lowers the total cost of ownership, and ensures a longer service life. 6.

4. High Accuracy and Reliability: Magnetic Flip Flop Level Gauges provide highly accurate level measurement, ideal for applications requiring precise measurements. In addition, external factors such as temperature fluctuations, foam and condensation have less impact on the magnetic flip-flop level gauge, which allows it to maintain excellent stability in a wide range of applications.

5. HART PROTOCOL COMPATIBILITY: It can be equipped with the HART protocol for digital communication for remote diagnostics and configuration. This optional feature provides additional flexibility, ensures easy integration with control systems, provides real-time data transfer and enhances operational efficiency.

Application Areas

Magnetic Flap Level Gauges have a wide range of application scenarios for a number of industries, including:

Chemical Industry: Handling corrosive liquids or chemicals that require accurate and reliable level measurement.

Oil and gas: Ensuring safe and accurate level measurement of crude oil, petroleum and other hydrocarbons.

Water treatment: monitoring liquid levels in water and wastewater treatment plants.

Food and Beverage: Ensuring that raw material levels in process tanks meet sanitary standards.

Conclusion

magnetic flap level kaidi provides a reliable low-maintenance liquid level measurement solution for industrial applications requiring high accuracy and reliability. Their durability, accuracy and safety make them ideal for handling corrosive, hazardous or high temperature liquids. By investing in kaidi's advanced flip-flop level indicator technology, industries are able to achieve more accurate level measurements while reducing operational risks and costs.

For more information on kaidi's magnetic flip-plate level indicators and other innovative level measurement solutions, feel free to contact us to learn how our products can enhance your industrial operations.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist