BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

I. What exactly is migration?

Simply put, migration is to adjust the measuring range of the level transmitter, so that it can accurately display the actual level. For example, if the level transmitter is installed in the wrong position, the medium is special, or the isolation fluid is used, the measured value may deviate from the real level, and then it needs to be ‘migrated’ to calibrate.

Migration is divided into three cases:

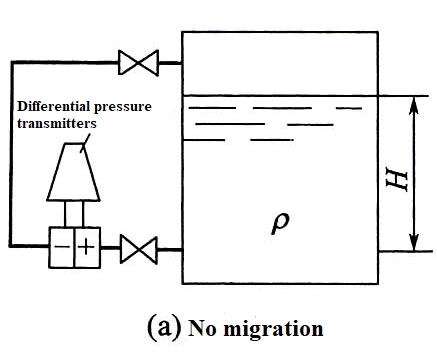

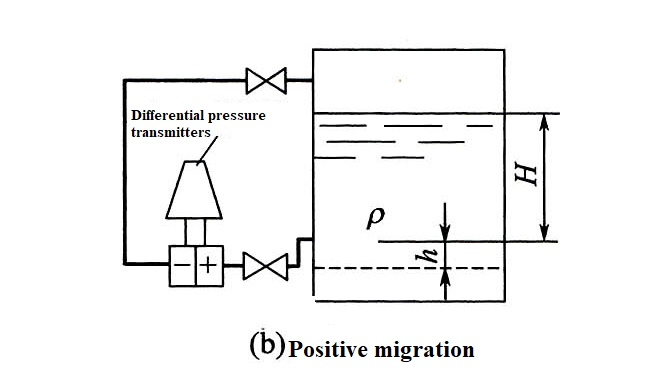

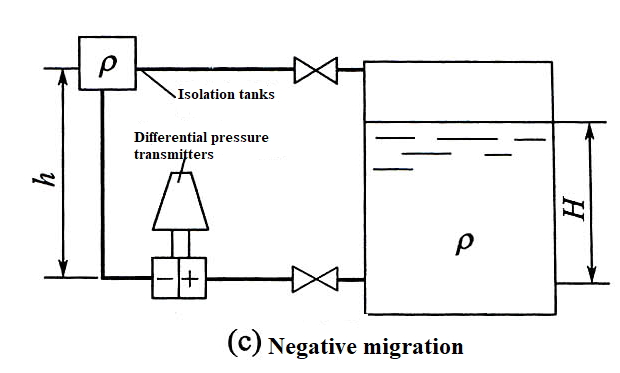

No migration:Measurement starts at 0, normal condition.

Positive migration:The starting point of the measurement is higher than 0 (e.g. the transmitter is already under pressure when the level is at its lowest).

Negative Migration:The starting point of the measurement is lower than 0 (e.g. the transmitter measures negative pressure when the level is at its lowest).

Caution! Migration is not the same as zeroing!

Zeroing: When the transmitter has no pressure (△p=0), adjust the output to 0.

Migration: When the transmitter has pressure (△p≠0), adjust the output to 0 (e.g., when the level is at its lowest, it shows 0, but there is actually pressure).

The amount of migration is usually expressed as a percentage of the pressure value or range.

For example, when we correspond the lower limit of the output of the transmitter (yₘᵢₙ) to the lower value of the actual measuring range (xₘᵢₙ):

If x ₘᵢₙ = 0, this is a zero adjustment;

If xₘᵢₙ ≠ 0, this is migration.

Depending on the direction of migration, this can be further subdivided as follows:

Positive migration: moving the starting point of the measurement above the ‘reference point 0’;

Negative migration: moving the starting point of the measurement below the ‘reference point 0’.

II. When do I need to migrate?

In practice, the following situations are basically migrations:

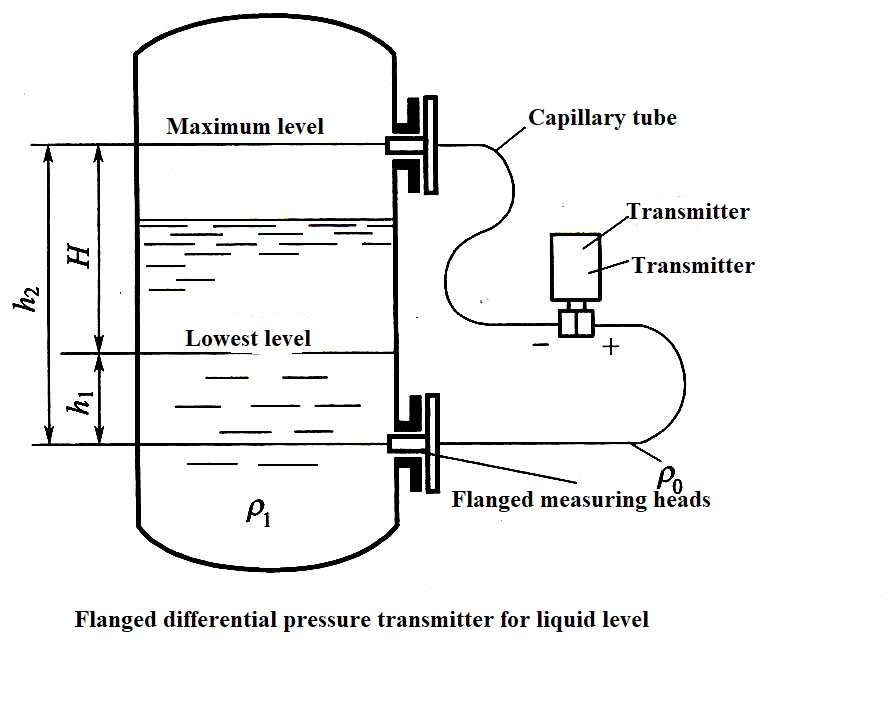

1.Double flange level transmitter

Scenario: sealed container, measuring high viscosity, easy to crystallise, strong corrosive media (such as chemical industry reactor).

Why migrate? The upper and lower flanges are installed at different heights, resulting in pressure difference, and the level display is not allowed if it is not relocated.

2. Monoflange level transmitter with capillary tube

Scenario: open tank or closed vessel.

Why relocate? If the transmitter is mounted higher or lower than the minimum level, the measured pressure will deviate.

3. Differential pressure transmitter with isolation tank

Scenario: Measurement of highly corrosive or viscous media (e.g. sulphuric acid, heavy oil).

Why relocate? The isolation fluid itself has a column pressure that affects the readings and must be calibrated.

III. Sharing of on-site experience

1. Quick Calibration of Double Flange Transmitter

Close the valve once and let both the upper and lower flanges ventilate (to air).

The PV value of the transmitter is the lower range limit (zero migration value).

Calculate the upper range limit according to the actual liquid level, and set it in directly.

2. The essence of migration

is actually to make the output signal (4~20mA) of the transmitter and the actual liquid level correspond to each other.

If the output is 4mA (0%) when the level is lowest, it is no migration.

If the output at the lowest level is >4mA (e.g. 8mA), it is positive migration; if <4mA (e.g. 0mA), it is negative migration.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist