BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Magnetostrictive level meter and magnetic flap level meter in a number of aspects there are significant differences, these differences are mainly reflected in the working principle, product structure, data display, measurement accuracy, measurement range and application occasions and so on. The following is a detailed analysis of these differences:

Differences in operating principles

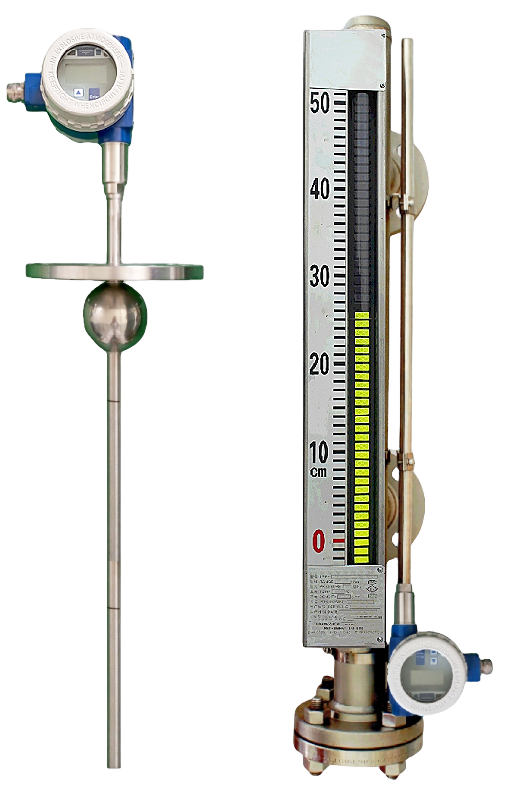

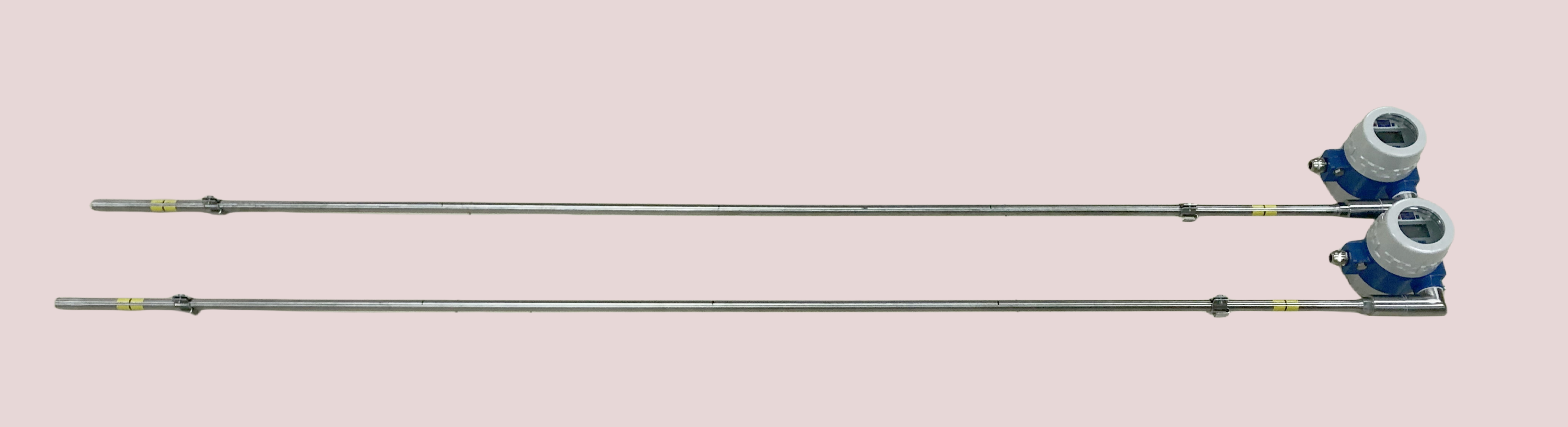

Magnetostrictive level gauges work on the basis of the magnetostrictive principle for liquid level measurement. The sensor of the magnetostrictive level transmitter is equipped with a float outside the measuring rod, which can be moved up and down along the measuring rod as the liquid level changes. Inside the float there is a set of permanent magnetic rings. When the magnetic field of the pulse current meets the magnetic field of the magnetic ring generated by the float, the magnetic field around the float changes so that the waveguide filament made of magnetostrictive material generates a torsion wave pulse at the position of the float, which is transmitted back along the waveguide filament at a fixed speed and detected by the detection circuit. By measuring the time difference between the pulse current and the torsion wave, the position of the float, i.e. the liquid level, can be precisely determined. Technical Advantages of Magnetostrictive Level Gauge: Magnetostrictive Level Gauge is suitable for level measurement of clean liquid level with high accuracy requirement, the accuracy is up to 1mm, and the accuracy of the latest products can reach 0.1mm. Magnetostrictive Level Gauge can also be applied to the boundary level measurement between two different liquids. Explosion-proof design, suitable for hazardous occasions, intelligent electronic circuit design can calculate the volume amount; the only movable part is the float, very low maintenance.

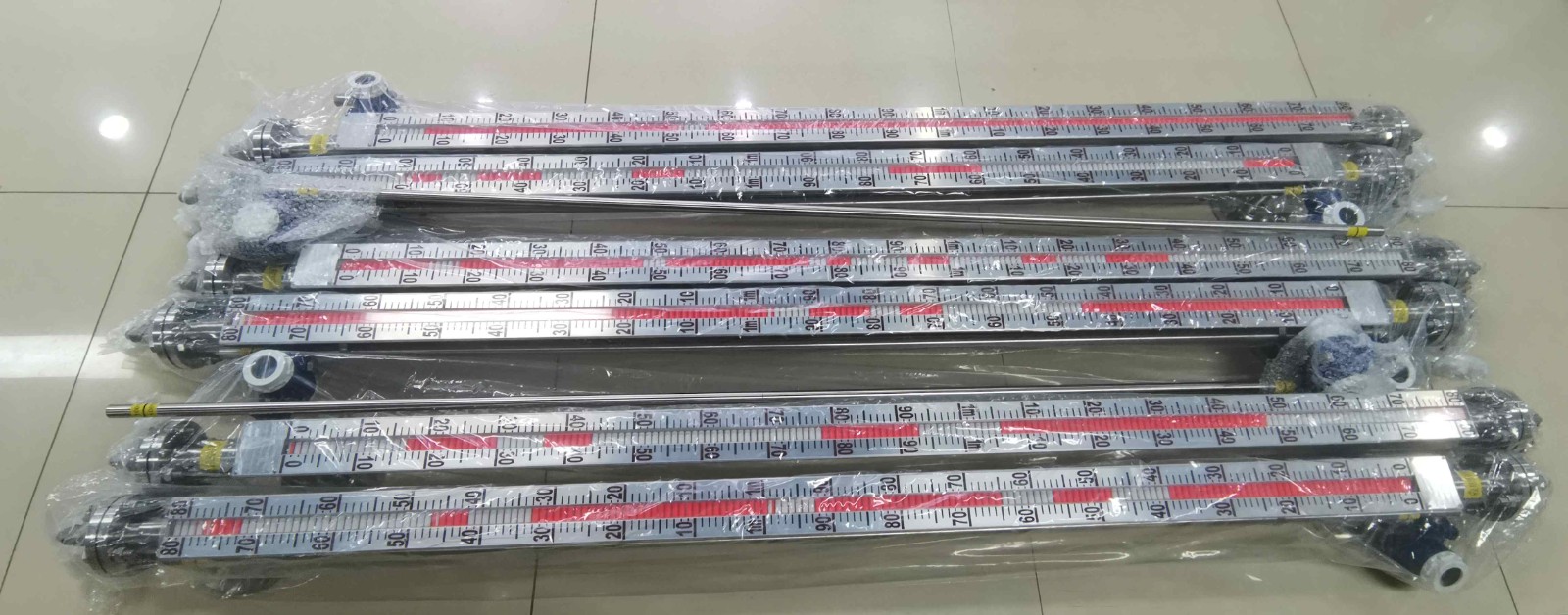

Magnetic Flap Level Meter

Magnetic Flap Level Gauge works on the principle of connectors and magnetic coupling. It uses a magnetic flap to indicate the liquid level, which consists of a fixed magnetic flap and a float equipped with floats. The magnetic float in the float rises and falls with the change of liquid level in the container, and the level is displayed by magnetically driving the external flip-flop or flip-column to rotate. Flip-flop indication accuracy is generally ±5 ~ 10mm, suitable for liquid storage tanks, storage tanks, underground storage tanks, etc., the level of on-site indication, but also can be equipped with a remote transmitter for long-distance display and monitoring, its installation is simple, easy to maintain, reliable, and is widely used in petrochemical, pharmaceutical production and other fields.

Magnetostrictive Level Transmitter

Different product mix

Magnetostrictive level gauge is mainly composed of the following parts:

Outer tube: used to protect the internal components and as a guide rod for the float to move up and down, it is required to be corrosion and pressure resistant;

Waveguide: located inside the outer conduit, composed of magnetostrictive material, is the core part of the level gauge, which is responsible for transmitting the magnetic field and strain pulse;

Floabuilt-in permanent magnet, moving up and down with the liquid level change. When the magnetic field of the permanent magnet inside the float intersects the magnetic field of the interrogation pulse on

the waveguide, a strain pulse is generated;

Electronic unit: generates low-current interrogation pulses and receives the returned strain pulses. By measuring the time interval between the interrogation pulse and the return pulse, the level value is accurately calculated.

Magnetic Flap Level Gauges, on the other hand, are mainly composed of the following parts:

Measuring Main Float Tube: The chamber used to hold the float, forming a connector structure with the vessel to be measured through a flange or other interface to ensure that the liquid level inside the main tube is at the same height as that inside the vessel to be measured.

Float Sensing Element: The float, which has been placed into the main measuring tube beforehand, follows the liquid level in the vessel as it rises or falls. There is a set of magnetic units fixed inside the float, the height of which is the same as the height of the corresponding liquid level.

Magnetic Panel Indicator: Usually bundled on the outer surface of the main body tube for real-time indication of liquid level. Under the magnetic coupling of the permanent magnets of the magnetic floats, the flip-flops inside the indicator are flipped to show the liquid level change in different colours (usually red and white).

Process connecting flange component: used for installation and docking with the vessel under test to ensure that the magnetic flip-flop level gauge can be installed and work correctly.

Drainage and venting components: mainly used for discharging the liquid in the main tube or air in the upper end of the venting tube during maintenance, and discharging sewage during cleaning.

Outer surface of main pipe

Different application characteristics

Applications of Magnetostrictive Level Sensors:

I. Magnetostrictive level sensor is suitable for level measurement of clean liquid level with high accuracy requirement, the accuracy can reach 0.1mm, so it is widely used in occasions requiring high accuracy measurement;

II. Suitable for petroleum, chemical raw material storage, industrial processes, biochemical, pharmaceutical, food and beverage, irrigation management and petrol station underground inventory and other kinds of liquid tank level industrial measurement and control;

III.Can work in high temperature, high pressure, corrosive liquids and other special conditions, showing a strong environmental adaptability.

magnetostriction

Magnetic Flip Plate Level Gauge applications:

I. Magnetic flap level gauge is suitable for general liquid level measurement needs;

II.Its structure is simple, easy to install and low maintenance, so it is widely used in the level measurement of various liquid containers;

III. Magnetic flap level gauge set on-site indication, remote transmission and transmission, alarm control open on one, fully functional;

IV.Continuous intuitive, eye-catching, large measurement range, the observation direction can be arbitrarily changed.

summaries

Magnetostrictive level gauges perform better in terms of accuracy and special environmental adaptability, and are suitable for high precision and special conditions of liquid level measurement. Magnetic flap level gauge is more suitable for general level measurement needs, its structure is simple, low cost, is a more cost-effective choice. When choosing a level meter, you need to consider the specific application requirements, environmental conditions and budget to ensure that you choose the most appropriate level measurement solution.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist