BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

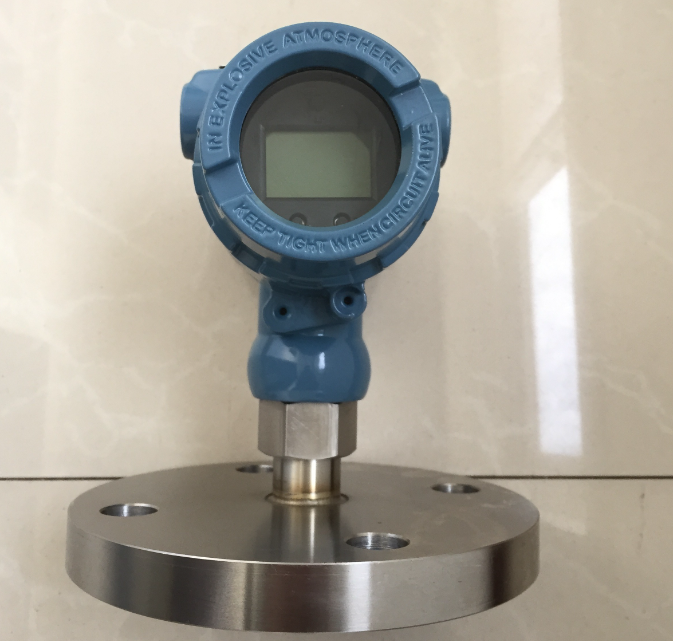

A pressure transmitter is an instrument used to measure the pressure of a liquid or gas, converting the pressure into an electrical output. Its function is to convert the pressure signal into a standard signal for easy processing and control in the automatic control system. In industrial production,china pressure transmitters are widely used in petrochemical, power, water treatment, pharmaceutical, food and other industries.

Pressure transmitters work by using piezoresistive or capacitive effects to measure pressure and then convert the pressure into a standard electrical output. Piezoresistive pressure transmitter adopts piezoresistive material. When subjected to pressure, the resistance value of piezoresistive material changes, and this change is converted into standard electrical signal output through the circuit; Capacitive pressure transmitters make use of the capacitance effect, when the pressure is applied, the capacitance value of the capacitor changes, and this change is converted into a standard electrical signal output through the circuit.

The working process of the pressure transmitter can be divided into the following steps:

1. Pressure sensor sensing pressure signal: When the liquid or gas is subjected to pressure, the pressure sensor will sense the pressure signal.

2. Signal conversion: The pressure sensor converts the pressure signal into an electrical signal, the piezoresistive pressure transmitter converts the pressure signal into an electrical signal through a change in resistance, and the capacitive pressure transmitter converts the pressure signal into an electrical signal through a change in capacitance.

3. Signal amplification: The electrical signal after signal conversion is small, and it needs to be amplified for easy processing and control.

4. Calibration: The vacuum pressure transmitter needs to be calibrated to ensure that the output electrical signal is accurate.

5. Output: After signal conditioning, the pressure transmitter outputs the standard electrical signal for the automatic control system to process and control.

When using a pressure transmitter, the following points need to be noted:

1. Installation position: The pressure transmitter should be installed on the liquid or gas pipeline in order to sense the pressure signal.

2. Selection: Appropriate pressure transmitter models and specifications should be selected according to actual needs.

3. Maintenance: Check and maintain the pressure transmitter regularly to ensure its normal operation.

In short, the pressure transmitter is an important measuring instrument, its role is to convert the pressure signal into a standard electrical signal output, in order to facilitate processing and control in the automatic control system. Pressure transmitters work by measuring pressure using piezoresistive or capacitive effects and converting it into an electrical output. When using the pressure transmitter, it is necessary to pay attention to the installation position, selection and maintenance.Want to know more, contact Kaidi Sensors, one of the best pressure transmitter manufacturers in China.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist