BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

The raw materials, semi-finished products and finished products used in the cement production process are generally granular or powdered solid materials, and the level measurement covers various occasions in cement plants, such as raw materials, pulverized coal, cement, mixed material storage, and process links such as grate cooler discharging and vertical kiln unloading. The material level switch is more widely used in cement plants, but due to inaccurate design selection, it cannot be well used in cement plants. Especially in cement enterprises with a low degree of automation, the owners may have the misconception that the level switch is useless, and even cancel the level switch to save investment costs, and finally rely on the most primitive manual measurement method of post inspectors in production, frequently inspecting to prevent full bins and consuming a lot of manpower. So, what is the role of material level switch in cement plant? How to correctly select the type in order to make it better to be applied?

I. The role of the material level switch

In the material storage of modern cement plant, the level meter is used to measure the actual height of the material in the reservoir (silo), while the level switch is used to detect the high material level in the reservoir (silo). In this regard, the level switch is an essential field instrument that effectively prevents the material from appearing full when the level meter fluctuates inaccurately and malfunctions. However, in the modern cement manufacturing process, which requires higher and higher automation control, only reasonable selection and application of the level switch can ensure the safety and reliability of material storage and ensure continuous and stable production.

Second, the selection of material level switch

According to the production process requirements, there are many kinds of material level measuring devices, one is the material level switch, generally there are two detection points of upper and lower limits, once the material surface reaches the pre-set material level, that is to send a control signal, so that the feeding or discharging equipment to carry out the corresponding action; the second is continuous material level measurement, there are several working methods of timing measurement and measurement when needed, for more accurate grasp of the material surface height occasions. There are several types of material level switches, such as tuning fork type, RF conductivity type, resistance rotary type and capacitance type, which are introduced as follows:

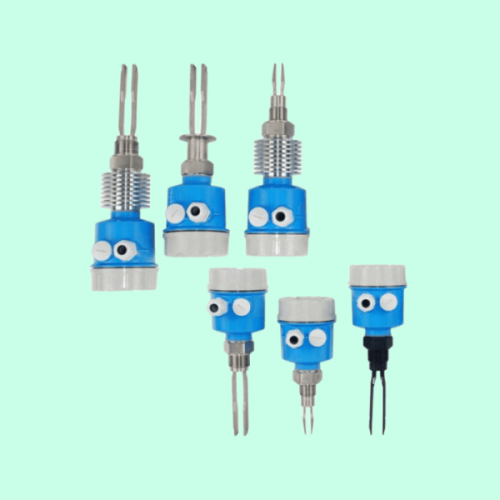

1、Tuning fork level switch

Tuning fork level switch is widely used in industrial sites, with high resistance to hanging material, strong sensitivity, and not afraid of material impact. Tuning fork level switch consists of piezoelectric crystal (oscillator), electronic circuit and detecting tuning fork. The tuning fork consists of a pole plate with two groups of piezoelectric crystals pressed at the end, one group is the driving element which drives the tuning fork to produce vibration, and the other group is the detecting element which transforms the vibration of the fork into voltage, and the two are connected to the input and output of the amplifier to form an oscillation circuit. When the fork body is damped by the solid material, the oscillator stops vibrating and the relay outputs a switch signal for the relevant action of the material level. If large particles accumulate between the two plates, it will affect the measurement accuracy, so the level switch is more suitable for the measurement of powder and small particles, so the tuning fork level switch is very suitable for the production of solid materials in cement plants.

2、Radio frequency conductivity level switch

RF conductor level switch uses high frequency technology to generate a low power RF signal on the probe by electronic circuit. When the measured medium covers the measuring pole of the probe, it will cause the change of reactance between the measuring pole of the probe and the tank causing the bridge circuit to be unbalanced and stop generating the oscillation signal, and the back stage circuit detects this change and outputs the alarm signal. The oscillation signal is applied to the measuring pole of the probe as RF signal, and at the same time, it is also sent to the protection pole of the probe after 1:1 voltage follower, the RF signal of the measuring pole and the protection pole has equal potential, same phase, same frequency and isolated from each other. RF level switch is developed on the basis of capacitance measurement, which has the advantages of better anti-hanging performance, more reliable work and more accurate measurement. Usually, RF conductor level switches can be used in various storage depots, grate cooler hoppers, bucket bottom and other equipment in cement plants.

3、Rotary level switch

It is composed of synchronous motor, disconnector, blade and overload detection mechanism. When the level of the material to be measured rises so that the rotation of the blade is obstructed, the detection mechanism generates a rotational displacement around the main shaft. This displacement will firstly cause a micro-switch to act to signal the presence of material and turn on the power to the motor to make it rotate; subsequently, another micro-switch will act to signal the absence of material and this state will remain as long as there is no material blocking the rotation of the detecting blade. The rotary level switch has the characteristics of simple structure, reliable operation and easy installation and use. The simple structure, low price, reliable operation and easy maintenance of the resistive level switch are generally used in cement plants for applications such as dust collector ash hoppers and the bottom of bucket elevators, and are also commonly used for high material level detection in powder material silos.

4、Capacitance type material level switch

The principle of capacitive level switch is that the electrode inserted into the silo and the silo wall form a capacitor, and when the change of material level in the silo causes the change of electric capacity, the corresponding control signal is obtained through the conversion circuit. Since the capacitance changes continuously, the level switch can be used as a continuous level measurement or as a level switch as an alarm or input signal for feeding and discharging equipment. The level switch has the features of low cost, no mechanical wear and tear, easy installation and maintenance, etc. Capacitive level switch is used for high material level monitoring in raw material storage, raw material storage, clinker storage and cement storage of cement plant, which can effectively prevent the occurrence of full bins when the material level switch but due to malfunction. Viscous materials are easy to stick to the probe and cause false operation, so for this kind of viscous materials then capacitive level switch is not applicable.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist