BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

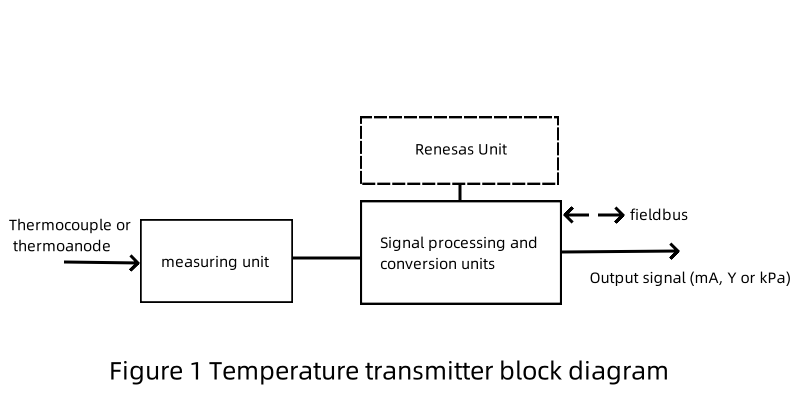

Temperature transmitter adopts thermocouple, RTD as the temperature measuring element, the output signal from the temperature measuring element is sent to the transmitter module, and then converted into the standard current or voltage signal which is linearly related to the temperature after processing by the circuits of regulator and filtering, arithmetic amplification, nonlinear correction, V/I conversion, constant current and inverse protection, and so on. It is mainly used for the measurement and control of industrial process temperature parameters.

Temperature transmitters usually consist of two parts: a measuring unit and a signal processing and conversion unit. Some transmitters add a display unit, and some also have a fieldbus function. As shown in Figure 1.

First, the temperature transmitter inspection, test methods

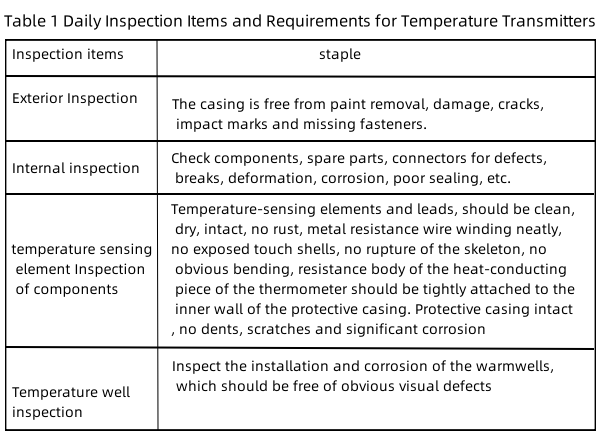

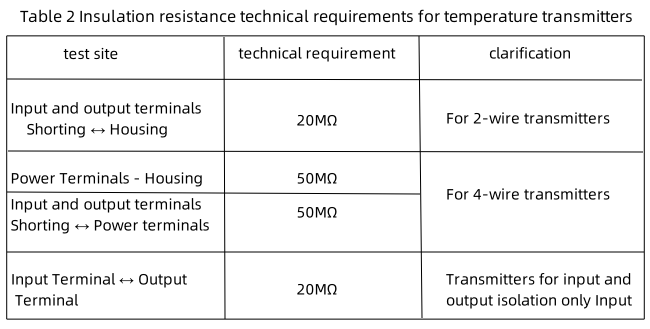

In the use of temperature transmitters should be regularly on the transmitter inspection and performance testing, temperature transmitter daily inspection items mainly include the contents shown in Table 1. In the daily inspection of the temperature transmitter at the same time, the temperature transmitter should also be measured performance and insulation performance for periodic testing, usually requires a test cycle of no more than 1 year. Temperature transmitter is insulation performance test should be carried out in the case of power failure. Remove the wiring with a 500V megohmmeter to test the transmitter terminals and shell insulation resistance between the resistance should be in line with the requirements of Table 2

Temperature transmitter measurement performance inspection can be used in two ways: with sensor test, without sensor test.

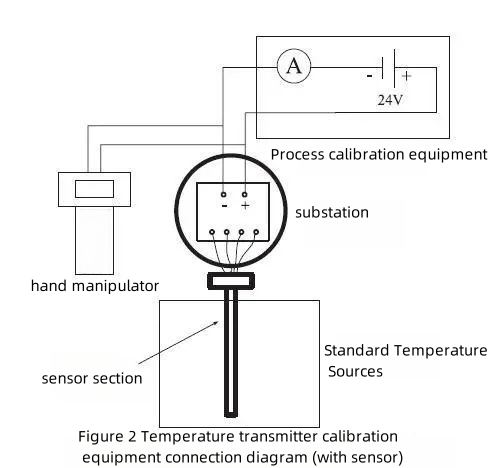

(1) with sensor test: the transmitter sensing part inserted into the standard temperature source, by changing the standard temperature input, calibration transmitter output current.

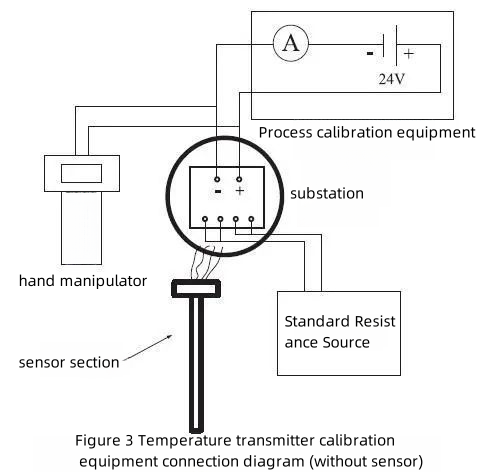

(2) Without sensor test: Disconnect the transmitter sensing element (RTD, thermocouple), use the standard resistance source and process test equipment, calibrate the signal conversion part of the transmitter alone.

Resistance temperature transmitter as an example, such as Figure 2, Figure 3 for the two inspection methods under the calibration equipment connection diagram.

In actual use, the temperature transmitter RTDs, thermocouples and other sensing elements of the failure and deviation of the chances of relatively low, the introduction of error is not large, usually can be used without a sensor for temperature transmitter inspection. In demanding places, or the performance of the sensing element and accuracy of the existence of doubt, it is necessary to use the way with the sensor for temperature transmitter inspection. Temperature transmitter measurement performance inspection is for the transmitter measurement error calibration [2], to determine whether to meet the accuracy requirements.

(1) Calibration point selection: the choice of calibration points should be based on the range of the basic uniform distribution, generally should include the upper limit value, lower limit value and range near 50%, including no less than five points.

(2) pre-calibration adjustment: in the case of disconnecting the sensor, the input signal with a change in the corresponding output of the lower limit value and the upper limit value of the adjustment, so that it is consistent with the theoretical lower limit value and the upper limit value.

(3) Calibration method: when calibrating the transmitter with a sensor, the measurement sequence can start from the lower limit temperature of the measurement range, and then measure sequentially from bottom up, and at each test point, the temperature within the temperature source should be stable enough to be measured; when calibrating the transmitter without a sensor, it should be started from the lower limit by smoothly inputting the signal value corresponding to each calibrated point, reading and recording the output value up to the upper limit, and then reversing the direction. Then change the input signal smoothly to each calibrated point, read and record the output value until the lower limit.

(4) Data processing: the principle of data processing in the process of measurement results and error calculation: the number of digits to be retained after the decimal point should be less than 1/10~1/20 of the maximum permissible error of the transmitter for the limit (equivalent to more than the maximum permissible error to take a decimal).

Second, the temperature transmitter tuning

In the process of temperature transmitter inspection, if the transmitter is found to exist zero drift, range drift, measurement error over the phenomenon, etc., the transmitter can be adjusted. Intelligent transmitter can use HART hand manipulator for tuning. Temperature transmitter tuning includes: sensor fine-tuning: adjust the factory characteristic curve, so that the transmitter has the best performance in a specific temperature range; analogue output fine-tuning: adjust the analogue output, so that it matches the factory standard or control loop.

First, connect the temperature source (analogue RTD, thermocouple source), the hand operated device and digital readout to the transmitter to enable communication between the transmitter and the hand operated device; select a calibration point to apply a standard temperature (RTD, thermocouple) signal; compare the applied temperature with the "Process Variable (PV)" on the Online menu of the hand operated device. Compare the applied temperature with the "Process Variable (PV)" on the operator's Online menu; if the PV reading on the operator does not match the applied standard temperature, fine-tune the sensor; compare the "Analogue Output (AO)" on the operator's Online menu with the reading on the digital readout. If the AO reading on the hand operated device does not match the reading on the digital readout device, the output should be fine tuned.

Third, the use and maintenance of the temperature transmitter

3.1 Installation of temperature transmitter

Temperature transmitter should be installed to ensure that the ambient temperature around: -25 ℃ ~ +70 ℃, try to be installed in the vibration or vibration of small places, the probe inserted into the depth of the best for the medium pipeline diameter of 1/2 ~ 2 / 3. Different types of temperature transmitters should be wired according to their respective instructions, such as two-wire, three-wire and four-wire system, for the safety of explosion-proof requirements for the instrumentation, the wiring of special attention should not be short-circuited. In the intrinsically safe explosion-proof system when using temperature transmitter with display, pay special attention to the use of matching isolated safety barriers.

3.2 Temperature transmitter maintenance and troubleshooting

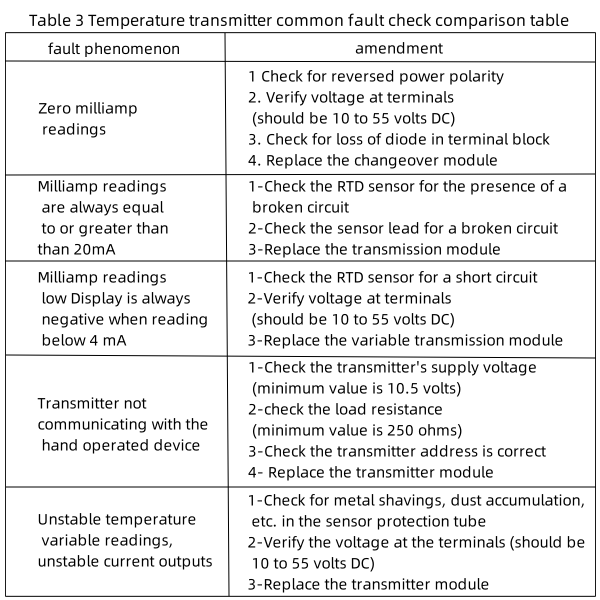

Transmitter in operation should be kept clean, parts and components intact. In principle, it is not allowed to dismantle the transmitter or instrument wiring with electricity, when it needs to be replaced or dismantled, it should be carried out after power failure according to the explosion-proof requirements. Regular checks should be made to verify whether the technical indicators meet the requirements. Typical faults and corrective measures of the temperature transmitter, as shown in Table 3.

IV. Concluding remarks

Temperature transmitter as the most commonly used temperature measurement instrumentation, its measurement performance not only depends on the temperature transmitter factory manufacturing level of the device, at the same time, the use of inspection and testing, effective routine maintenance and reasonable troubleshooting is also an important means to ensure that the equipment long-term precision, effective.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist