BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

We all know that in the conveying system, the operating condition of the belt conveyor protection devices is directly related to the safety of the equipment and personnel in the production process. Therefore, how to make the belt conveyor protection device stable and reliable in the production operation to give full play to the role of safety protection, has a very important practical significance. It is very easy to cause the belt to break and even affect the safety of the personnel, so it is necessary to install these protection devices on the conveyor. Commonly, there are two kinds of devices to prevent conveyor runout and slippage.

There are two kinds of devices to prevent conveyor runout and slip: runout switch and slip switch, here we explain their selection and installation respectively, as well as some matters to be noted. Here we will explain the selection and installation of these devices, as well as some points to note, to facilitate users' understanding and selection.

The runout switch is a protection device used to detect the degree of belt runout during the operation of the belt conveyor and alarm. It is also used to automatically trigger an emergency stop when the belt is seriously deviated. The runout switch is fixed on both sides of the speed switch for belt conveyor at a certain interval (about 50m). The roller part of the deflection switch deflects when it is squeezed by the edge of the conveyor belt running away from the center, and triggers the switch contact when the roller deflects to a certain angle. When the roller deflects to a certain angle, it triggers the switch contact action.

Selection principles and precautions.

(1) Try to choose two-stage or multi-stage runout switches, which can detect different degrees of belt runout and provide more information for the control system.

(2) Give priority to products with action memory and action status indication on the switch body. As the stainless steel belt conveyor is running dynamically, having this function can facilitate the determination of the belt runout.

It is easy to determine the specific location of belt deviation and analyze the cause of deviation, and also easy to debug and maintain the equipment.

(3) Non-contact runout switch can be selected if necessary. The non-contact runout switch is a photoelectric proximity switch instead of a roller to detect whether the belt is running out of alignment. The advantages are long life and easy maintenance, but the disadvantage is that it is expensive.

(4) The products corresponding to the measurement range should be selected according to the actual movement speed of the belt conveyor being detected. Usually the belt speed is about 2.5-4m/s and the drum speed is about 50-300rpm during the normal operation of the conveyor. in addition to the comparative slip switch which detects the drum speed and the belt speed separately and compares them, it is better to use the product which can automatically avoid the low speed when the belt conveyor starts.

(5) Since the slip alarm of the coal belt is actually a low speed alarm, the slip alarm should be shielded during the start of the conveyor, which can be detected by delaying the start of the conveyor (i.e. delaying the start for a - time, and then turning on the power of the slip switch after the belt conveyor reaches normal speed), but it is troublesome to realize.

(6) Some products can automatically avoid the low speed state when the conveyor starts: the conveyor starts while giving power to the slip switch, and the slip switch is powered on and then delayed for a period of time before it starts to detect the belt speed normally. Try to choose the product with actual speed display and can transmit speed signal remotely.

Installation method and precautions .

(1) Choose a reasonable installation spacing. Belt runout mostly occurs at the head and tail ends, so the runout switch should be installed within 15m from the head and tail of the conveyor, and the installation distance of the runout switch in the middle of the sway switch belt conveyor should generally be controlled within 50m as far as possible.

(2) Select a reasonable runout range according to the process requirements of the conveyor equipment. Generally, the runout displacement of the belt should not be allowed to exceed 1/5 of the belt width, and the belt should not be allowed to runout and touch the side fixing mechanism. The allowable runout range at the head and tail ends of the belt should be controlled at least between the support mechanisms on both sides of the roller jenny.

(3) The mounting bracket of the runout switch should be made in such a way that the position of the runout switch can be adjusted laterally along the belt. This is to adjust the allowable runout range in a small range according to the actual situation on site.

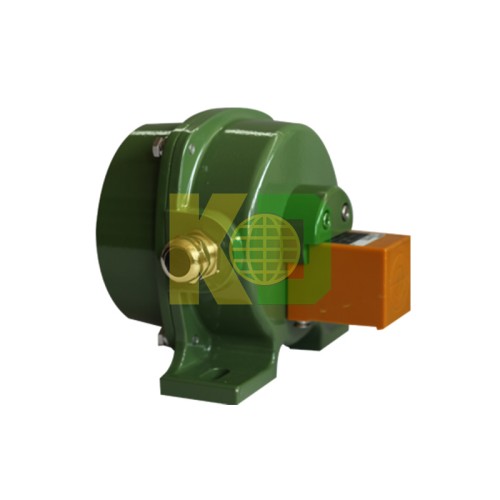

A slip switch is a protection device that detects slippage between the belt and the drive pulley and provides an alarm, which can be used to automatically trigger an emergency stop when a belt conveyor slips. There are many different types of slip switches, with different working principles and detection methods. For example, according to the detection method, there is a contact wheel type slip switch that directly detects the conveyor belt speed and compares it with the set standard speed; there is a slip switch that detects the driven wheel speed and compares it with the set standard speed; there is a contrast type slip switch that simultaneously detects the roller speed and the conveyor belt speed and compares them separately; according to the internal working principle, there is a magneto-resistive type, magneto-electric type, photosensitive type and so on. Many slip switch devices can also provide real-time signal display and output of conveyor belt line speed or drum speed.

Choose the appropriate installation method according to different product types. Non-contact slip switches should be installed as far away from strong electromagnetic field interference as possible. and covered with a metal cover. The setting of the slip alarm should be set after the field measurement. The speed parameters of each stainless steel belt conveyors are generally different. The actual belt speed is also influenced by the way the conveyor is installed and its structure, so the slip switch must be set one by one for each conveyor. Therefore, the alarm value of the slip switch must be set for each conveyor individually.

By installing two types of protection devices for belt conveyors by belt conveyor factory, namely runout switches and slip switches, the chance of conveyor failure can be effectively reduced. The installation of runout switches and slip switches can effectively reduce the chance of conveyor failure, reduce downtime, and better protect the conveyor and personnel.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist