BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Radar level meter is a more commonly used level measurement instrument, which has the characteristics and advantages of accurate measurement, easy maintenance and wide application, and is quite popular. However, in the actual application process, due to the more complex working conditions or improper use and other reasons, there are often failures. In this paper, the common problems and solutions in the application of radar level meter are introduced as follows.

Generally speaking, the failure of the radar level meter often occurs in the process of instrument commissioning and instrument use.

A, the instrument commissioning process often occurs in the fault

Radar level meter in the commissioning process often appear in the measured value is too large, the measured value frequently jump to the maximum immobile, the display value dead in the zero value and other failures. The following are a few examples of the situation.

1, improper selection of failure caused by

Radar level transmitter according to the different measurement principles, there are two types of instruments, ordinary and precision. The ordinary type uses the pulse time travel measurement principle PTO, the accuracy of this type of instrument is general, the emission angle is large, poor anti-interference echo capability, the price is low, suitable for general occasions.

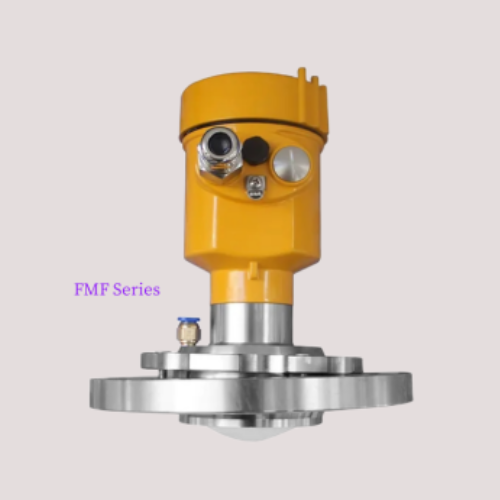

Precision type adopts frequency conversion continuous wave technology FMF, which has small emission angle, concentrated energy, strong anti-interference ability, high accuracy, and can measure certain solid materials, generally used in complex environments such as steam, turbulence, mixing, foam, etc.

If the type is not selected properly, for example, in a complex environment, the choice of poor anti-interference ability, instrument range is too small ordinary type radar level meter, the measurement will not be allowed to occur. The use of precision radar level meter can be avoided.

2、Malfunction caused by improper installation

If the radar level meter is not installed properly, it will cause interference echoes. In actual application, there are often cases that the radar is not installed perpendicular to the liquid level, installed above the feed port, or installed above the agitator, the antenna extends out of the receiver 10mm, etc., so that the radar can not be measured stably.

(1) The instrument is installed above the feed port fault

If the radar level meter is installed in the location too close to the feed port, the material level will often jump up and down or the measurement value will die in the highest value when feeding. After reselecting the installation position and avoiding the feeding mouth, the meter can basically measure stably.

(2) The instrument is installed above the stirrer failure

The level measurement of the tank with agitator is usually measured by a precision instrument with wavelet processing software. Two aspects should be noted in the application:

First, the correct setting of parameters, in addition to the setting of empty tank, full tank, but also need to set other parameters such as application conditions to select the option with agitation or with foam; second, the storage of false echoes, false echo storage is to deal with interference echoes caused by obstacles in the tank, generally can only store the obvious echoes caused by obstacles in the tank. For false echoes that have been measured above the material level are automatically stored in the false echo list after confirming that they are false echoes. For the false echoes that will be caused below the material level, if you know the exact location of the obstacle, you can manually input a value and store it in the false echo list.

3、Some faults that can be solved by using parameter setting

During the instrument commissioning process, after familiarizing with the working conditions, the setting parameters of the instrument should be checked. Including basic parameters such as the type, size and material of the antenna, the height, shape and type of the tank, the type of the tank bottom, the environment inside the tank, etc. Advanced parameters are threshold value of signal amplitude, upper blind area, lower blind area, full tank handling, empty tank handling, tank bottom visibility, surface echo tracking setting, etc. If a fault occurs when the tank is full or empty, the corresponding parameters can be adjusted to eliminate it according to the situation.

Second, some of the faults that often occur during the operation of the instrument

1, the impact of steam

Fault performance: steam on the rod antenna impact is slightly larger, often appear measurement value up and down jump or measurement value error, etc..

Solution: generally wipe the antenna on the condensation clean or instrument parameters reset reset parameters after normal.

2, the impact of the probe scarring

Fault performance: probe scarring generally for the horn antenna, the instrument in operation for a period of time after the radar level measurement probe sticky dust, dielectric constant of very small hanging material in the dry state does not affect the measurement, while the dielectric constant is very high hanging material has an impact on the measurement.

Solution: If it affects the normal measurement, the antenna needs to be cleaned, generally available compressed air blowing (or water rinse), but also available acid cleaning solution to clean the alkaline scars.

After cleaning dust and scars, the instrument work back to normal, but during the cleaning period can not be level measurement.

3, radar level meter broken cable phenomenon

Cause of failure: The main reason for the breakage of the steel cable connected to the antenna probe is the high temperature and pressure difference in the tank, which is caused by the reciprocal stretching and bending of the steel cable.

Solution: If the length of the steel cable is enough, the probe can be reinstalled and the position of the top signal bar magnet can be adjusted from the new, can continue to use. If the steel cable is not long enough, you can deal with the following methods.

(1) installation of new steel cable. One end of the steel cable into the round hole at the bottom of the circle wheel, the steel cable butt, and then fastened with a steel tie head, and then a circle counterclockwise up around. The new steel cable must be wound tightly and arranged neatly, otherwise it will clip the rope failure.

(2) instrument in the state to be measured cut off the power supply, at the end of the steel cable and transmitter connection, you can use metal adhesive and ring clamps to fix. In addition, you can also by welding the steel cable with a nut, fixed with bolts on the radar type level transmitter.

4, the instrument does not indicate

Solution: In case of this fault, check whether the power supply and communication cable are normal for troubleshooting.

5, the instrument has a fault code

Solution: Clear the fault code, if it cannot be cleared, refer to the fault code list for corresponding treatment or contact with the radar level transmitter manufacturer.

Radar level meter is the most widely used, accurate and convenient level meter among all kinds of level measuring instruments. In the process of using radar level sensor, there are often unstable, incorrect or no echo and other failure phenomena, mostly caused by interference echo, in addition to the selection of strong radar level meter or guide wave radar, the best installation location, suitable antenna type and slightly larger size, but also can be selected with a strong function of processing interference echo multi-echo processing software instrument, in order to make false echo suppression, false echo hosting, so that Interference echoes can be separated from the actual surface echoes.

KD-FMF21 high frequency pulse radar level meter is a 123GHz high frequency pulse radar level meter with continuous frequency modulation, specially designed for solid material level measurement with a range of 0.3~150m. The unique aiming device (gimbal) design can adjust the antenna emission angle according to the field conditions, which effectively improves the reliability of inclined solid material measurement. The product can be applied in the application of high dust and high temperature materials, which is very popular among users.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist