BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

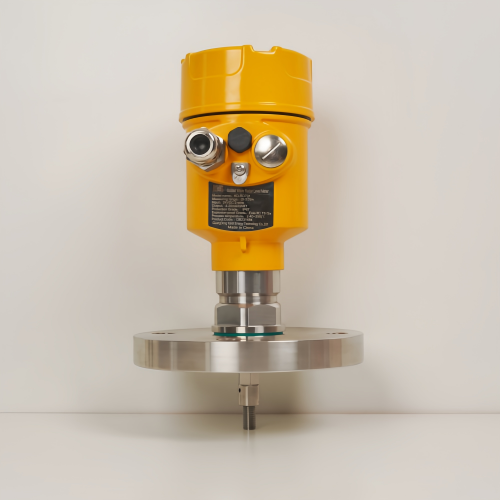

Radar level meter is a new type of liquid level measurement instrument, in the petrochemical industry is particularly widely used. In the production process, people will often be due to this new instrumentation lack of sufficient familiarity and troubleshooting methods, in a timely and useful solution to the failure of the radar level meter when exacerbated radar level meter failure, this paper is based on the failure of the radar level meter common problems put forward some of the solutions, the use of theoretical analysis and field tests combined with the method of briefly explain the causes of the failure of the meter, through the analysis and demonstration of the causes of failure, and finally summed up some of the radar level meter troubleshooting methods. By analysing and arguing the causes of the failure, and finally summed up some of the radar level meter troubleshooting methods.

1. Measured value error

The fault manifests itself in the fact that the trend of the actual level and the measured value is consistent, but the values are not equal. This is a common, simple and easy to eliminate the fault. Using the traditional rope measurement method to measure the real distance above, if the measured value is consistent with the distance above the instrument display, it proves that the quality of the instrument itself is not a problem. By the working principle of the radar level meter can be seen, the actual liquid level by the empty tank distance E minus the measurement of the reference point to the surface of the media distance D obtained, and thus the height of the empty tank must be accurate in order to ensure that the measurement is accurate and reliable, so the calibration must be measured in the field before to obtain the real data. If the instrument is connected to the computer system, you should also check the instrument full-scale parameters and computer configuration data is consistent.

2. Measured value is obviously distorted

Failure to show that the liquid level changes and the measured value is constant, when the tank is empty or will be full of instrumentation to maintain a clear false level, or the tank will be full of material for the tank display pops back to a low value. This type of failure is usually caused by the following reasons:

(1) Antenna scarring. Thick and wet scarring will strongly reflect the microwave, so that the instrument measurement value to maintain a constant high level value.

(2) Interference echoes from the antenna or nearby condensate when the material is empty.

(3) The fixed components in the tank cause strong echo when the material is emptied. For the above situation should take the following methods to solve:

(1) Carefully clean the antenna and the cohesive material near the antenna.

(2) Activate and reasonably set the "window suppression" distance. "Window suppression", also known as "near-site suppression", is an effective means of optimising the measurement by eliminating the influence of welding seams on the mounting flange, the antenna or hanging material in the vicinity of the antenna on the measurement. By setting the near-site suppression distance, the instrument registers echoes within this range as interference echoes and does not measure them.

(3) "Fixed component echo suppression". In addition to the intelligent filtering of interference echoes by the software, the customized radar level meter can also perform fixed component echo suppression by registering interference waves.

(4) the tank will be full of material when the instrument shows a lower level, is due to the liquid level rise in the tank multiple echo increase, the procedure will be processed by the beam time stroke longer echo incorrectly identified as a measurement of the echo, thereby calculating a larger distance over the air. In this case, the near-site suppression distance should be modified to eliminate the effects of multiple echoes.

3. Measured value fluctuations

Measured values fluctuate in the tank due to sharp undulations in the surface of the mixing medium or due to temporary interference echoes in the tank caused by underfeeding. In addition to improving the application parameters (activation of the floating-point averaging curve algorithm), activating near-field suppression, increasing the output damping, you should also check the installation position of the instrument or consider installing a larger antenna.

In my experience, in the case of card-powered two-wire instruments, it is also important to check that the DCS analogue input card has sufficient load-carrying capacity. Sedimentation 160 tank radar level meter has been measured by the liquid level of smooth but violent fluctuations in the measured value of the fault, in a comprehensive examination of the DCS system was determined to be the AI card with load capacity is not enough. Instrumentation from the card channel power supply to external power supply mode, the measurement signal through the isolator into the card, the instrument failure disappeared.

4. Loss of wave

Failure to show that the instrument appears "wave loss" error or crash. In the measurement of low dielectric constant liquid, because of the weak reflective ability of the liquid, the phenomenon of wave loss often occurs, but in the alumina industry does not exist in the weak reflective ability of the liquid, so the wave loss is mostly due to the vortex, turbulence of the liquid surface, thick and thick foam so that the radar wave diffusion or absorption, and thus the return wave is weak or even no return wave. In this case, the optimum application parameters should be set according to the process characteristics of the vessel. If the above measures do not have a significant effect, the antenna should be installed in a different location or in a larger size in order to increase the return strength. The use of waveguide or bypass tube is an effective way to solve the frequent loss of wave phenomenon, but the installation workload, and is not suitable for easy scarring slurry.

Radar level meter is currently all kinds of liquid level measurement instruments in a wide range of applications, accurate measurement, easy maintenance of the species. With the further reduction of price, cost-effective improvement, the application will be more and more extensive, in the liquid level measurement to play an increasingly important role. Optimisation of measurement, should start from the selection, installation and other root causes, and then in use to take good measures to eliminate interference, in order to maximize the reduction of the chance of instrument failure, truly reflect the characteristics of its reliability, high accuracy, for the production process control to provide accurate basis.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist