BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

In the use of magnetic flap level gauge will often encounter some complex working conditions, this time it is necessary to magnetic flap level meter manufacturers to make targeted improvements and enhance the production of the product in order to make it get good application. So today let's talk about manufacturers in the production should go to which process enhancement.

1、Optimize the design of the product structure: improve the product structure design. Reduce the jointing surface of the product. Jointing surface is the product structure of dustproof and waterproof design is relatively weak, the production of most of the dust, water vapor and impurities are also through the jointing surface into the product inside, so the design of the jointing surface should be strictly controlled; in addition, in the manufacturing process, the tolerance must comply with the provisions, if the tolerance is too large products will exist in the gap, resulting in the entry of dust and water vapor, the tolerance is too small will make the contact parts overstress, resulting in the deformation of the product. If the tolerance is too large, there will be gaps in the product, which will cause dust and vapor to enter. In the manufacturing process, the tolerance should be in accordance with the provisions, not too large and too small.

2, the sealing auxiliary technology to improve: because the product sealing auxiliary technology mainly has sealing ring, sealant, surplus fit, waterproof breathable membrane, welding and so on. Different sealing auxiliary materials on the sealing effect has an important impact on the existence of internal and external conduction gap channel, so in the use of sealing ring or sealant to start sealing, be sure to select the sealing auxiliary materials to meet the needs of the working conditions, the use of dust and moisture will be along the gap channel into the internal structure of the product, so the sealing auxiliary process should be used to carry out the reinforcement. In the use of seals or sealant process, the selection of sealing materials to meet the requirements of the working environment, in the selection, special attention should be paid to the sealing of auxiliary materials, such as working temperature, strength and other material properties, in the bolted place, but also pay special attention to the design of the product's external mounting screw holes, can not be directly connected to the internal structure of the product or with the product's internal holes connected to the product. This is due to the presence of magnetic flap level gauge products inside and outside the gap channel, the use of dust and water vapor will be along the gap channel into the internal structure of the product, so in the development of the reinforcement, the need to improve the sealing of auxiliary technology according to the application of the differences in working conditions.

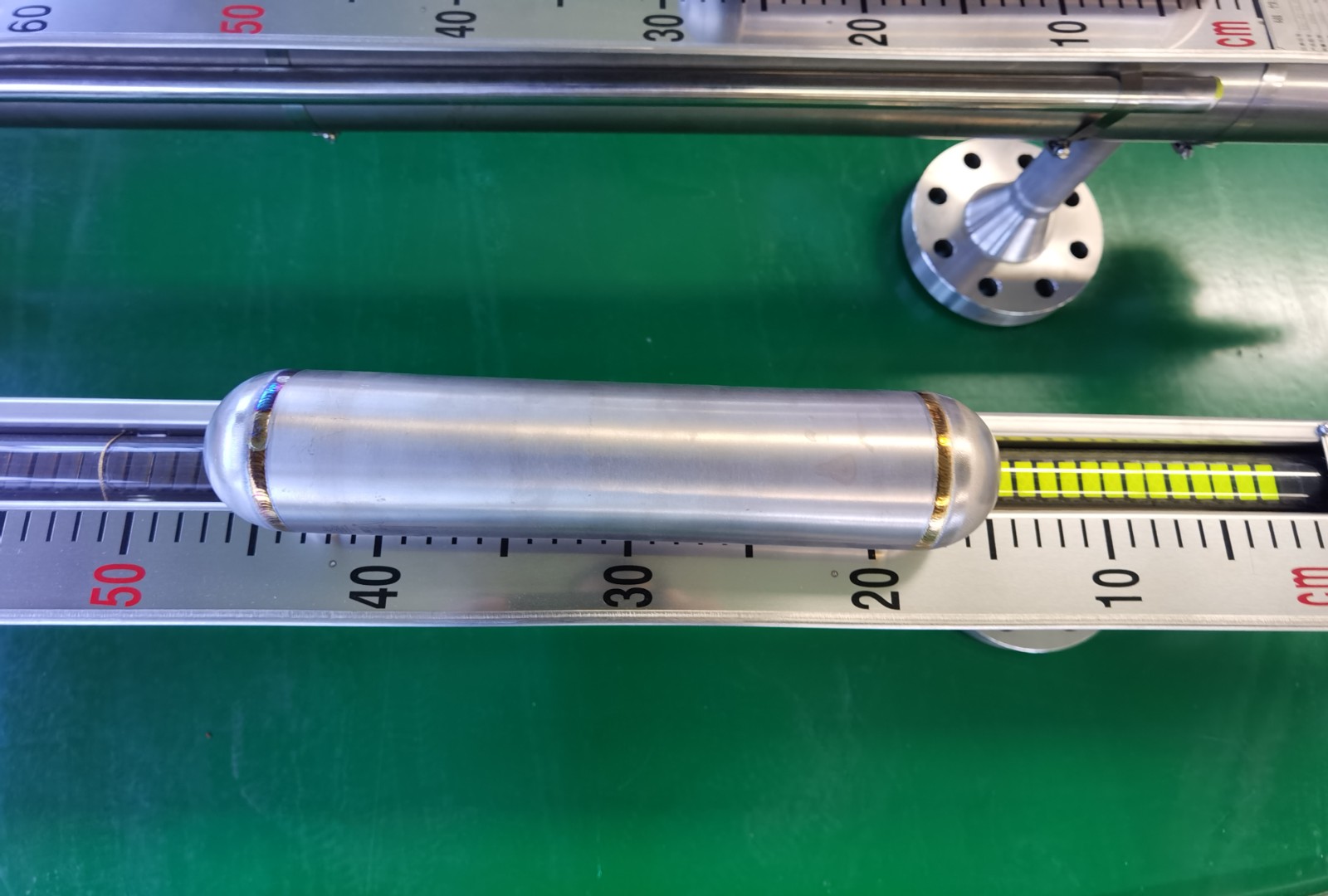

Magnetic flap level meter manufacturers for the production of more severe conditions, in order to ensure that the level meter sealing effect is obvious, but also the use of glass sealing, and with the vacuum and nitrogen filling method for targeted improvement, improve the structural design of the improvement and sealing of auxiliary technology to improve the work of two aspects, so that the magnetic flip-flop level meter to achieve a higher level of protection.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist