BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

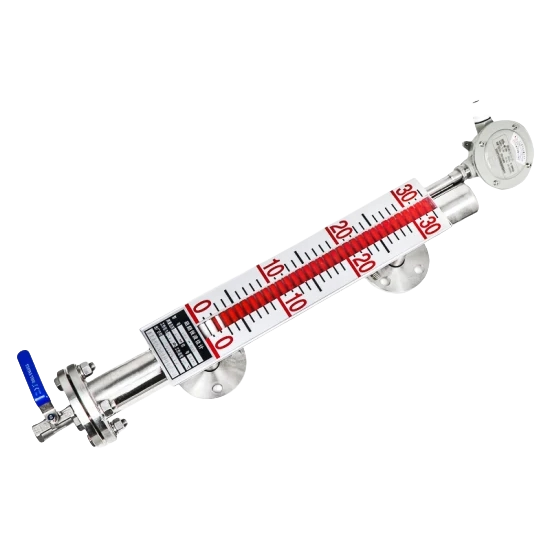

Magnetic Flip Plate Level Gauge is widely used in food and beverage industry, but when using it, you need to pay attention to some issues to ensure the accuracy and reliability of the measurement results, as well as to ensure the hygiene and safety of the production process. The following is a detailed description of the matters that need to be paid attention to in the application of magnetic flap level meter in the food and beverage industry.

I. Material Selection

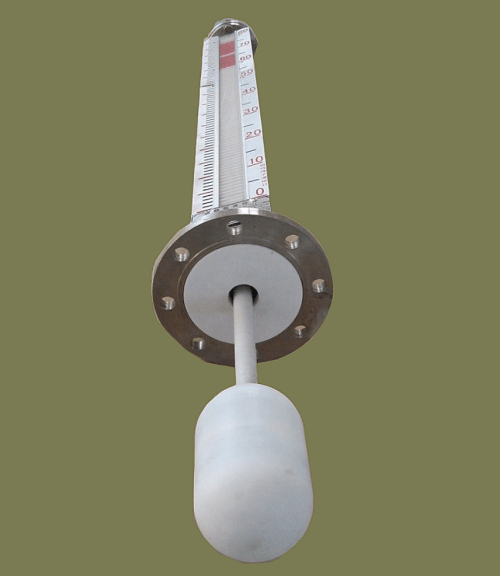

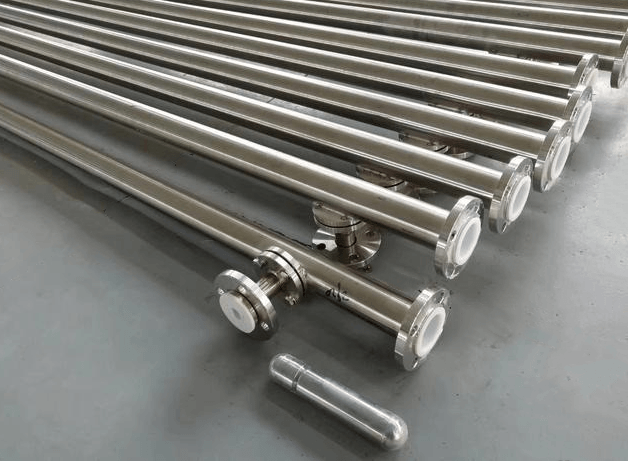

Since the food and beverage industry has very high hygiene requirements, when choosing a magnetic flap level meter, you need to choose a material that meets hygiene standards. Generally speaking, the part in contact with the liquid should be made of stainless steel, such as 304, 316, etc. These materials have good corrosion resistance and hygienic performance, which can ensure that the liquid is not contaminated. At the same time, the sealing material of the magnetic flap level gauge should also be selected to meet the hygiene standards, such as food-grade silicone, fluorine rubber, etc., to ensure good sealing performance and prevent liquid leakage.

II. Installation

When installing the magnetic flip-flop level meter, you need to pay attention to the installation method to ensure the accuracy and reliability of the measurement results. Generally speaking, the magnetic flap level meter should be installed on the vertical pipeline, and the measuring range should be within the effective measuring range of the level meter. At the same time, in order to avoid the influence of liquid level fluctuation on the measurement results, a flow stabilizer can be added to the installation position of the level meter to ensure smooth liquid flow. In addition, because the magnetic flip-flop level meter works through the magnetic coupling principle, it is necessary to pay attention to whether there is magnetic field interference in the surrounding when installing it, if there is magnetic field interference, it may lead to inaccurate measurement results of the liquid level meter.

III. Cleaning and maintenance

Since the food and beverage industry has very high hygiene requirements, regular cleaning and maintenance is required when using magnetic flap level gauges to ensure the hygienic performance and measurement accuracy of the level gauge. Generally speaking, the level meter should be cleaned after each use to remove the liquid and dirt attached to the level meter. At the same time, regularly check whether the magnetic flap of the liquid level meter is flexible, if there is any jamming phenomenon, it should be repaired or replaced in a timely manner

IV. Periodic calibration

In order to ensure the accuracy and reliability of the measurement results, it is necessary to calibrate the magnetic flap level gauge periodically. The calibration period should be determined according to the frequency of use and working conditions and other factors, generally half a year or a year. In the calibration process, it is necessary to use the standard liquid level meter to compare the magnetic flap level meter, and adjust the magnetic flap level meter according to the comparison results.

V. Security considerations

When using the magnetic flap level meter, you should pay attention to safety matters in order to avoid safety accidents. Firstly, when installing and dismantling the magnetic flap level gauge, the valve should be closed first and the liquid in the pipeline should be emptied to avoid liquid leakage and injury. Secondly, in the process of use, the magnetic flip-flop level meter should be avoided to be subjected to strong shock and vibration, so as not to affect its measurement accuracy and service life. Finally, when cleaning and maintenance, the power supply should be cut off first, and wear good protective gear to avoid electric shock accident.

VI. Environmental considerations

In the food and beverage industry, the production environment is usually affected by temperature, pressure, humidity and other factors. These environmental factors may affect the measurement accuracy of the magnetic flap level meter. Therefore, it is necessary to choose a suitable magnetic flip-flop level meter according to the specific production environment and take corresponding protective measures. For example, if the temperature of the production environment is high, you may need to choose a high temperature resistant flip-flop level meter; if the pressure of the production environment is high, you may need to choose a high pressure resistant flip-flop level meter.

VII. Compatibility with other equipment

In the food and beverage industry, magnetic flip-flop level gauges usually need to be used in conjunction with other equipment, such as control systems, valves and so on. In order to ensure the normal operation of the whole production system, it is also necessary to ensure the compatibility of the magnetic flip-flop level meter with other equipment. When selecting the magnetic flap level meter, the type of interface with other equipment, signal output method and other factors should be considered, and the matching equipment should be selected according to the actual situation.

Conclusion

In conclusion, magnetic flap level meter is widely used in food and beverage industry, but when using it, you need to pay attention to the selection of material, installation method, cleaning and maintenance, regular calibration, safety precautions, consideration of environmental factors and compatibility with other equipment, etc., in order to ensure the accuracy and reliability of the measurement results, so as to ensure that the whole production process is carried out smoothly.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist