Product Description

High-quality stainless steel casting, high strength, never rust, IP67 protection rating, and good sealing. Pull Cord Switch is an emergency switch to stop the belt conveyor instantly when an accident happens. Since the Pull Cord Switch is so designed that it should be installed at the side of belt conveyor and the pull cord should be mounted along conveyor, the switch can be actuated at any position. Weatherproof type: IP67. The internal contact is the high performance micro switch from Japan, with high contact capacity. It can directly control high capacity contactor, with 2 normally open and 2 normally closed output. Additionally, we also produce pull cord switch with the internal contact close to the sensor .

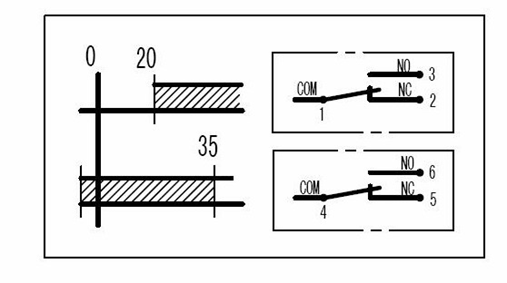

WIRING DIAGRAM

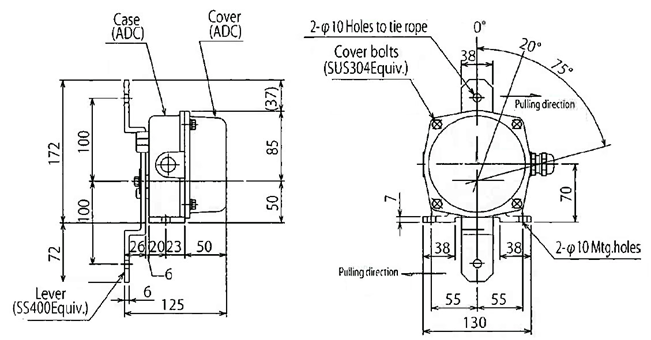

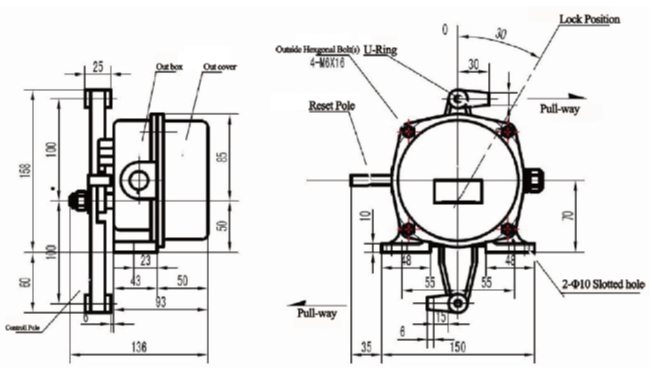

Drawings

a. Auto-reset

b. Manual reset

ENVIRONMENTAL CONDITIONS

The Pull Cord Switch should be used in the following environmental conditions; especially made products should be used at the allowable conditions noted in the approved drawing or the final drawing.

l Temperature -10°C~+50°C

Do not use the Pull Cord Switch in the place where there is danger of freezing.

l Humidity less than 80%

l Dust

If much dust adheres to the touch roller and it solidifies the Pull Cord Switch will not move normally.

To prevent dust from adhering to the touch roller, it should be cleaned at regular intervals.

l Explosive and Corrosive Environment

The standard Pull Cord Switch should never be use under these conditions.

INSTALLATION

Fitting bolts

The fitting bolts should be prepared before installation, and should be fitted into the mounting holes according to the length.

Mounting Base

The mounting base fitted to the belt conveyor should be prepared before installation. When you are deciding the dimensions of the mounting base, refer to Product drawing.

Installation

Prepare the necessary installation frame according to the size of the belt conveyor frame

MAINTENANCE

Periodic Inspection

(1)Cleaning

Always clean when an excessive amount of dust accumulates on the touch roller.

(2)Action check

Check to see if the Pull Cord Switch is working normally by Pull the cord.

Lubrication

The Pull Cord Switch has no need to lubricate.

Tightening of Cover

When taking off the cover of Pull Cord Switch for the sake of writing, adjusting and checking, secure the screws of the cover after working, or the Pull Cord Switch may cause trouble due to water and dust entering from between the cover and casing.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist