BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Level sensors play a vital role in industries that rely on continuous level measurement. By detecting the level of a medium in a tank or silo, these sensors convert the data into an electronic signal that can be integrated with a process control system. As the need for accuracy and real-time data increases, liquid level sensors have become an indispensable tool in a variety of industries, including chemical, food and beverage, oil and gas, and more.

Working Principle of Liquid Level Sensor

Level sensors are used to detect the level of liquids, solids or powders in tanks and silos. Depending on the material and environmental conditions, different sensor technologies are used, such as radar, ultrasonic and capacitive sensors.

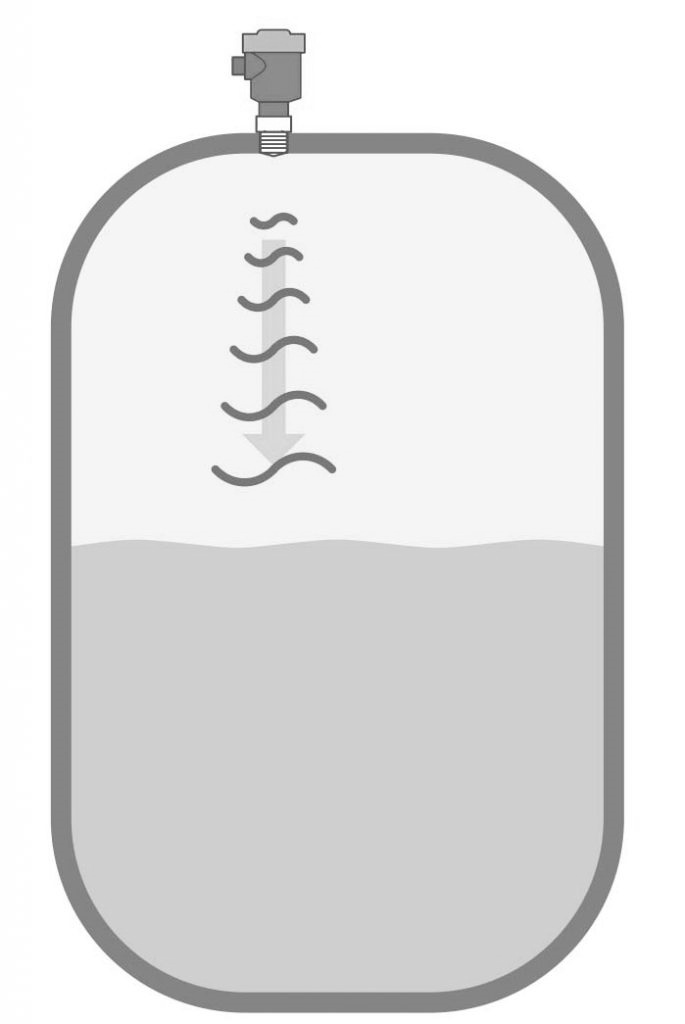

For example, kaidi's radar level sensors utilize microwave signals that are emitted to the surface of the material. When the signal hits the surface, the signal is reflected back to the sensor. By calculating the time it takes for the signal to return, this data provides accurate level measurements in real time. The non-contact operation ensures high accuracy and reliability, making it ideal for a wide range of applications.

kaidi radar sensors: precise non-contact level measurement

1. Optimize process control

Level sensors allow industries to continuously monitor material levels, providing real-time data to ensure optimal process conditions. By using kaidi level sensors, operators can easily make adjustments to keep processes running smoothly and prevent problems such as spills, underfeeds or inventory errors.

2. Improve efficiency and reduce downtime

By continuously monitoring material levels, kaidi level sensors help the industry to anticipate potential problems and make adjustments before they cause disruptions. This helps reduce downtime and improve operational efficiency.

3. Cost-saving solutions

Continuous level measurement reduces the need for manual inspection, lowering labor costs and human error. kaidi's level instruments also offer low maintenance requirements and long-term durability, reducing overall operating costs.

4.Wide range of industry applications

Level sensors are a critical tool for many materials, from liquids to granular solids. kaidi's sensors are particularly well suited for the following industries:

Chemical Manufacturing:Ensure precise control of liquid levels in mixing and storage tanks.

Food & Beverage:Monitor raw material levels to ensure production consistency.

Oil & Gas:accurately manage tank levels to ensure accurate inventory.

Cement Plants:Measure levels of bulk materials such as cement and gypsum.

5. Reliability and Safety

kaidi's level sensors help industries maintain strict safety protocols and reduce potentially hazardous situations in challenging environments by providing accurate and reliable data that ensures high sensitivity while meeting safety regulations.

Why kaidi?

kaidi is committed to providing level sensors that meet the highest standards of accuracy, durability and ease of use. Here are some of the reasons why many industries prefer Meters for Level Instrumentation:

Non-contact measurement:avoids abrasion, contamination and corrosion, suitable for harsh environments.

High accuracy:ensures accurate measurement of even the smallest level fluctuations.

Long-term durability:Designed to withstand extreme environments, ensuring long-term stability.

Easy integration:kaidi's sensors can be easily integrated into existing process control systems with little or no impact on ongoing operation.

Applications for kaidi level sensors

kaidi's level sensors are highly versatile and suitable for a wide range of industries and applications. Whether it's a liquid, powder or granular material, kaidi's sensors provide reliable and accurate measurements to help you effectively manage your process.

Conclusion

Level sensors are an integral part of continuous level measurement, offering many benefits such as optimized process control, increased efficiency and cost savings. kaidi's level instruments are designed to provide accurate and reliable measurements across a wide range of materials and industries. Whether you are in the chemical, food, petroleum or cement industries, kaidi's level instruments can help you optimize your operations, reduce downtime and ensure compliance with safety regulations.

With kaidi's level instruments, you can achieve the continuous and accurate monitoring that is essential to keep industrial processes running smoothly and efficiently.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist