BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

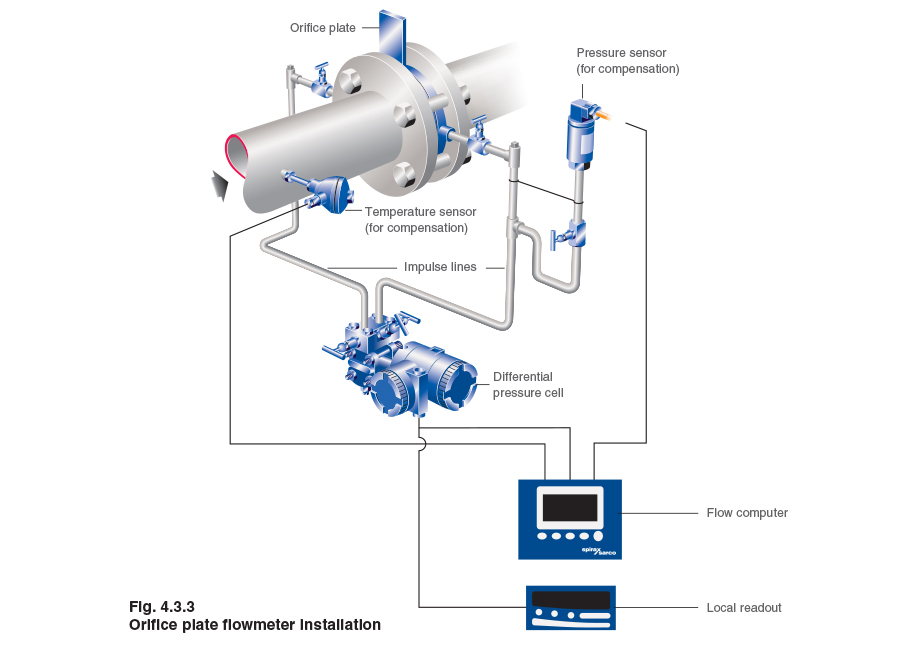

Installation is the first step in preparing all equipment for use. The correct installation will directly affect the normal operation of the equipment in the future. For orifice flowmeters, what aspects should we pay attention to during the installation and construction process?

1. Pipeline conditions:

1) The straight pipe sections before and after the magnetic flowmeter must be straight without obvious bends.

2) The straight pipe section used for the throttling part of the device should be smooth. If it is not smooth, the flow correlation coefficient should be multiplied by the roughness and correction coefficient.

3) In order to ensure that the medium forms a fully developed turbulent velocity distribution in front of the throttle, and the distribution is averagely an axisymmetric shape, the cross section of the straight pipe must be round before and after the throttle, and the throttle must be strictly required The roundness. Detailed weighing method:

A. OD, D/2, D, 2D in front of the throttling piece on 4 vertical pipe cross-sections, with at most equal angular intervals, measuring 4 pipes with a single measured value of inner diameter, taking the uniform value D. The difference between a single measurement value and the average value of the inner diameter shall not exceed ± 0.3%

B. After the throttling part, 8 single measured values of inner diameter can be measured by the above management method in the OD and 2D positions. Compared with D, the large single measured value has a very large impact on the enterprise not to exceed ±2%.

2. Do not make a mistake in the direction of the orifice, install it in the direction of the arrow, and the direction of the arrow should be consistent with the flow direction of the medium.

3. The orifice plate is generally used with a differential pressure transmitter. When the pressure guiding tube and the differential pressure transmitter can be connected, pay attention to the positive and negative pressure not to be reversed.

4. The gas pressure should be at the top of the pipeline, and the liquid pressure should be below one side of the pipeline, not directly below the pipeline, because the particles there will block the pressure, and the vapor pressure should be on the side of the pipeline.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist