BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

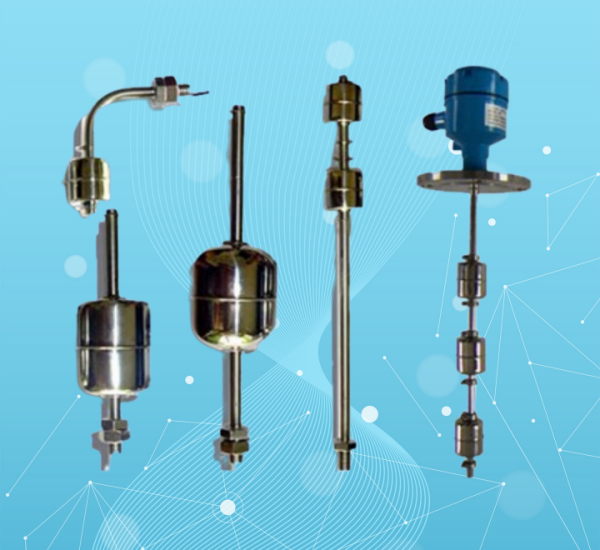

Float level meter is a simple installation and reliable continuous level measurement instrument, widely used in chemical, metallurgical, electric power, paper making, food and industrial wastewater treatment industries, for measuring the level of water in water towers, pools, tanks, water collection pits and industrial tanks and other media level measurement.

In order to ensure that the float level meter can work normally and reliably, the correct installation of the float level meter is very important. So, how should a float level meter be properly installed?

In general, when installing the float level meter, the following points should be followed.

1, in order to prevent the float from slipping or crashing at high speed on the seal tube during transportation, causing the measuring belt to come off, so the instrument is fixed with clamps at the bottom of the seal tube and magnets at the top of the seal tube before leaving the factory. Users should remove the clamp before installation and use, the float will rise to the top of the sealed tube, then gently move the float down, the pointer should make a corresponding rotation.

2、Before installation, it should be confirmed that there should be no ferromagnetic impurities in the measured liquid and around the level meter, and the specific gravity of the medium should be greater than the specific gravity of the float, otherwise it will affect the normal operation of the level meter.

3, the instrument must be installed vertically in the float up and down movement is not obstructed position, in order to ensure that the float in the main tube can move up and down freely.

4、The installation position of the float level indicator should be far from the liquid inlet, otherwise the float will be prone to fluctuations due to the liquid inlet injection and cause misoperation.

5, for the range of more than 3.5 meters level meter, need to add support ears at the bottom of the guide rod to strengthen the guide rod to make it more stable.

6、The zero point and full range position of the level meter range are generally set according to the user's needs at the factory, please do not reset at will, so as not to cause abnormal detection.

7, when the float type level indicator after a period of time, if the float is difficult to float or float move insensitive condition, generally due to the magnetic float float guide rod hole stained with iron filings or other dirt, at this time, you can first empty the media, after removing the float, and remove the float stained with iron filings or other dirt, and then re-installed can

KD KD LF-Float Level Switch SUS304/SUS316/PP/PE/PTFE series float level sensor adopts imported plastic sealed reed tube, and pay attention to process details, strictly control the production process and quality inspection, to ensure the product has super high reliability, nevertheless, users still need to follow the above requirements for proper installation, so that the meter can function better.

The above is the introduction of "how to properly install and use float level switch", if you want to know more about level switch (level switch, liquid level switch), level meter (level meter, liquid level meter) and other level measuring instruments, welcome to pay attention to us!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist