BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

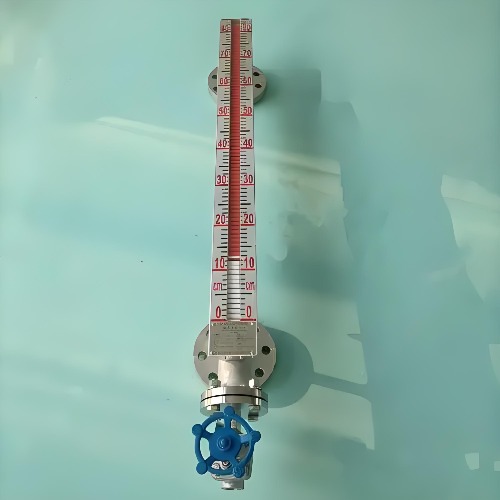

Magnetic flap level meter also known as magnetic flip column level meter, magnetic float level meter or magnetic float level meter, magnetic flap level gauge has high sealing, anti-leakage characteristics, to make up for the poor clarity of the glass plate (tube) level meter indication, easy to rupture and other defects, and the whole process of measurement without blind spot, clear display, large measurement range, can be applied to high temperature, high pressure and corrosion-resistant occasions, to meet the explosion-proof, telecommunication, heat preservation and other aspects of the working conditions required, and so on. It can be used for medium level detection of various towers, tanks, troughs, spherical containers and boilers.

According to the general instrumentation installation specifications, in fact, the installation and use of the magnetic flip-plate level meter itself is not complicated, but the magnetic flip-plate level meter also has its own unique characteristics, the application of the working conditions are very different, the installation of the need for appropriate adjustments. If you do not pay attention to the installation and use of magnetic flap level meter will often appear in the process of some of the problems, which requires us to pay special attention to the installation and use of magnetic flap level gauge in the process of common problems in order to avoid. Below, the common problems in the installation and use of magnetic flap level meter and the treatment method are introduced as follows:

Problem 1: In the process of on-site adjustment of the magnetic flap level meter, occasionally you will find that the magnetic float does not move up and down flexibly enough.

Solution: This situation is usually caused by improper installation of magnetic flap level meter. At this time, we should pay attention to observe whether the center of the upper and lower flanges of the magnetic flap level meter is in a line, and whether it is perpendicular to the horizontal plane. Generally speaking, the angle with the horizontal plane is better not less than 87 degrees, if the bias is larger, it may affect the smooth movement of the magnetic float.

Problem 2: The magnetic flap level meter is adjusted normally, but after put into use, it is found that the magnetic float in a certain position presents a period of time of "sucking" phenomenon.

Solution: This situation is mainly due to the fact that the magnetic flap level meter is too close to the steel plate when it is installed through the steel platform. Therefore, when installing through the steel platform, we need to pay special attention to the spacing between the pipe wall of the magnetic flip-plate level meter and the cutting edge line of the platform. Generally speaking, this distance can be controlled at about 100mm to ensure that the magnetic float is not affected.

Problem 3: In the process of using the magnetic flip-flop level meter, the output signal generates frequent disturbance or the phenomenon of interference pulse.

Treatment: This time we should check whether the shielding layer is firmly grounded, the work is connected to the resistance can meet the request. If the interference is still not completely eliminated, the signal isolator can be used for processing.

Problem 4: When the magnetic flip-flop level meter is put into use on site, the magnetic float is crushed and the float causes the magnetic flip-flop level meter can not be used normally.

Solution: Since the bottom of the connecting pipe of the magnetic flip-flop level meter is equipped with a thrust spring to maintain the magnetic float, when using the magnetic flip-flop level meter, the upper gate valve should be opened first, and then the lower gate valve should be opened. Otherwise, under the action of huge differential pressure, it will be easy to smash the float and cause the magnetic flap level meter can not be used normally.

Problem 5: In the process of using the magnetic flap level meter, the magnetic float is weakened, and it is difficult to work normally.

Solution: Magnetic float magnetic weakening is likely to be caused by strong magnet interference. So be careful not to use a strong magnet to pull the float up and down outside the connecting tube for checking, otherwise it will lead to magnetization of the magnetic float and change the polarity, which will weaken the float magnetism and make it difficult for the magnetic flaps to work normally.

Problem 6: After the magnetic flap level meter has been put into use for a period of time, it appears that the magnetic float is difficult to float and the magnetic float moves inflexibly.

Solution: This situation is mainly due to the magnetic float stained with iron filings or other dirt. The magnetic float can be eliminated by first emptying the medium and then removing the magnetic float to eliminate the iron filings or other dirt on the magnetic float.

The above six cases for the use of magnetic flap level meter in the process of the most common failure phenomenon, we usually in the use of the process, should be targeted to avoid, in order to ensure that the magnetic flap level meter can work stably and normally.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist