BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Among the many instruments for measuring the level of liquids or solids, radar level meters are favoured for their high accuracy and non-contact measurement.

However, to ensure the accuracy and stability of the radar level meter, the correct installation is crucial. Among them, the flange, as a key component connecting the piping system, undertakes the important task of fixing the radar level meter firmly on the storage tank or pipeline. In this article, we will explain in detail how to correctly install the flange to fix the radar level meter to ensure the accuracy and reliability of its measurement results.

Firstly, let us understand what is flange.

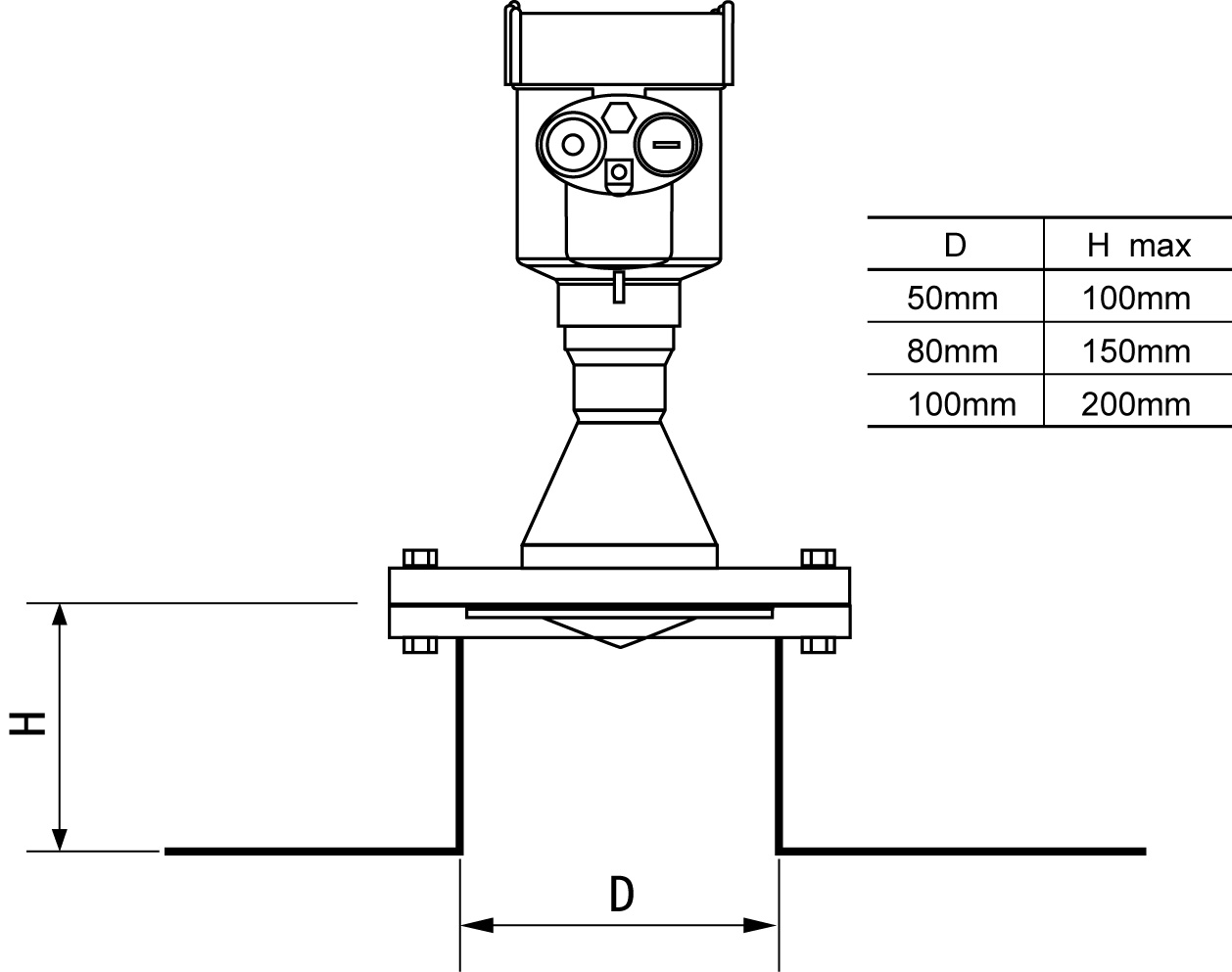

Simply put, a flange is a round metal piece used to connect pipes, which usually has a number of bolt holes around its periphery, and through the matching bolts and nuts, it can realise the close connection between pipes and pipelines, pipelines and instruments. In the application of radar level meter, the flange is both the support body and the connection medium, and its stability is directly related to the normal operation of the measuring equipment. Adequate preparation is required before carrying out the flange fixing steps. This includes determining the specifications and dimensions of the required flange, selecting the appropriate type of radar level meter, and preparing the necessary tools such as spanners, bolts and sealing gaskets. In general, the diameter of the flange should match the diameter of the interface of the radar level meter and be adapted to the pressure level of the pipeline in which it is located. Next comes the installation process. The first step is to interface the radar level meter with the matching flange. During this process, it is important to note that the bolt holes in the flange should be aligned with the openings in the level gauge to ensure that the fixing bolts can subsequently be fitted correctly. The selected sealing gasket is then placed between the flange and the level gauge to ensure a tight connection.

Immediately after that, use the bolts and nuts to tightly connect the radar level meter to the flange. During this step, care needs to be taken to tighten the individual bolts crosswise and progressively to ensure that the force is evenly distributed and to prevent poor sealing performance or damage to the equipment due to uneven forces. In addition, the tightening torque of the bolts should be controlled in accordance with the manufacturer's instructions, as too loose a tightening torque may result in leakage, while too tight a torque may crush the sealing gasket or damage the threads. After securing the flange, the installed radar level gauge needs to be inspected. The inspection includes confirming that all bolts have been properly tightened, that the sealing gasket is not broken, and that the level gauge is vertical. If necessary, appropriate adjustments can be made to ensure that its verticality and stability meet the requirements.

Finally, the installation needs to be tested after completion. Inject an appropriate amount of medium into the storage tank or pipeline and observe whether the radar level gauge can accurately reflect the level change. At the same time, check whether there is any leakage point to confirm the stability and sealing of the whole system. Correct installation of flanges is crucial to the stable operation and accurate measurement of radar level meter. Through careful selection of flanges, strict adherence to installation steps, and meticulous inspection and commissioning, we can ensure that the customized radar level meter will perform at its best in its post and provide strong technical support for all kinds of liquid level monitoring. In today's increasingly important industrial automation and fine management, mastering these seemingly simple but critical installation skills is of non-negligible value in enhancing the efficiency and safety of the entire system.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist