BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

In the era of “smart manufacturing,” “Industry 4.0,” and “smart automation,” digital transformation has become a buzzword in the industrial sector. From cloud-connected SCADA systems to AI-driven analytics and 5G-enabled device communication, many believe that traditional factories can easily transform into future smart factories by simply deploying a few sensors and connecting to a cloud platform.

However, those who have actually participated in engineering projects know that the success and stability of a system often do not solely depend on software, communication protocols, or platforms, but rather on a more fundamental yet often overlooked physical variable——dielectric constant

1. Why is the dielectric constant a “basic parameter” in industrial automation?

The dielectric constant (εr) is a measure of a material's ability to respond to an electric field, and is typically covered in basic materials science courses. However, in actual automated systems, this parameter often determines the difference between stable operation and unexplained malfunctions.

It directly affects:

●Electromagnetic signal transmission

●Capacitive and radar level measurement

●Sensor response accuracy

●Electromagnetic compatibility (EMC/EMI) interference resistance

Dielectric constant drift caused by temperature changes, material differences, or improper material selection can lead to signal attenuation, response delays, measurement errors, or system failure.

In short:

Unstable dielectric constant = signal distortion = unreliable automated systems.

II. Dielectric Constant: The Invisible Key in Sensing and Measurement

Unlike many static physical constants, the dielectric constant is dynamic and environment-dependent, varying with temperature, frequency, pressure, humidity, and material composition.

●Radar level gauge: Echo intensity depends on the dielectric constant.

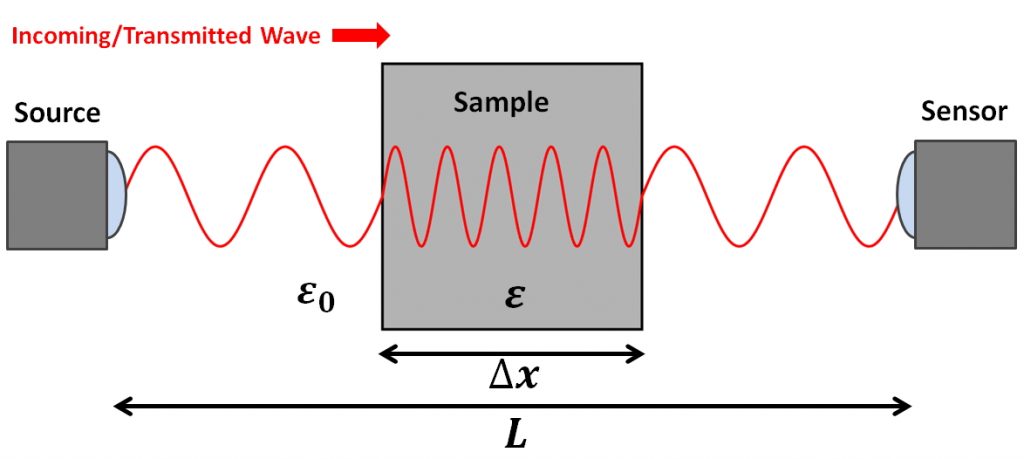

Radar level gauges measure liquid levels by detecting the reflection of electromagnetic waves, with the strength of the echo signal being directly proportional to the dielectric constant.

Liquids with low dielectric constants (such as hydrocarbons) produce weak reflection signals, which can easily lead to signal loss and misinterpretation.

High-dielectric-constant liquids (water, acids) produce strong signals, but these are subject to significant fluctuations due to foam, steam, and mixtures.

Real-time dielectric compensation is particularly important and requires hardware and software collaboration to adjust the frequency and match the wavelength to the dielectric properties.

●Capacitive level meter: Measurement accuracy depends on the dielectric constant of the material.

Capacitive level meters measure material levels based on changes in the capacitance of the material inside the container, with the dielectric constant being the key determining factor.

Dry powders or particles with low dielectric constants produce weak signals, making accurate detection difficult.

Wet materials or plastic particles with high dielectric constants can easily cause false alarms.

By modeling dielectric characteristics and dynamically calibrating thresholds, measurement reliability can be improved in complex material environments.

●Electromagnetic flowmeter: Signal stability is affected by fluctuations in the dielectric constant.

Electromagnetic flow meters measure flow based on the induced voltage generated by conductive fluids in a magnetic field. The dielectric properties of the fluid affect magnetic field interaction and signal quality.

Fluids containing bubbles or multiphase fluids cause changes in dielectric constants, resulting in unstable signals.

High-solids-content fluids such as slurries have large spatial dielectric differences, increasing the difficulty of compensation.

Modern systems rely on real-time dielectric tracking and intelligent signal filtering algorithms to correct measurement errors.

●Humidity sensing: dielectric constant reflects moisture content

Dielectric sensors detect humidity by measuring changes in dielectric constant after the material absorbs water. High-precision measurements require temperature and pressure compensation, as well as spectral separation of bound water and free water, to avoid linear assumption errors.

In summary, dielectric constant is not only a source of interference but also a rich source of multidimensional signals.

3. True engineering design begins at the physical layer.

Modern automated systems are becoming increasingly complex and cannot rely solely on modular design and plug-and-play functionality. The root cause of instability in many systems lies in a superficial understanding of physical fundamentals—focusing solely on component parameters without understanding electromagnetic fields and material responses.

The future trend in industrial design is the deep integration of physical-layer data and control algorithms, while The dielectric constant is precisely the core variable.

This will drive innovation in three major areas:

●Material design: Multi-component composite materials regulate dielectric constants to achieve sensor miniaturization and performance stability.

●Intelligent sensing: Combining physical modeling with artificial intelligence, dielectric changes are treated as core signals rather than noise.

●Physical engineering: Engineers need to master dielectric spectrum analysis, electric field distribution, and dielectric response to go beyond traditional parameter interpretation.

Conclusion: Understanding the fundamentals, building a solid foundation for the future

Today's automation industry is like the early steel industry: on the surface, it competes on scale and speed, but at its core, it competes on control of physical laws.

The dielectric constant is not just something left over from textbooks; it is the cornerstone of stable operation in intelligent industrial systems. Ignoring it will inevitably lead to the collapse of even the most advanced automation architecture.

In the era of intelligent automation, only by delving deeply into the physical essence can we build high-performance, reliable systems.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist