BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Protective baffle is a kind of baffle which mainly plays the role of protection. Usually use a certain thickness of stainless steel or iron plate, installed in a certain shape in the instrument probe above, to prevent the instrument probe suffered a direct impact of the falling material, in order to increase the service life of the instrument, and at the same time to prevent the probe due to the impact of the material to produce false alarms, to ensure that the instrument is stable and reliable work.

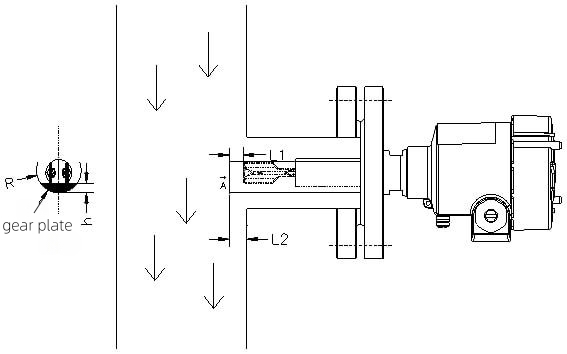

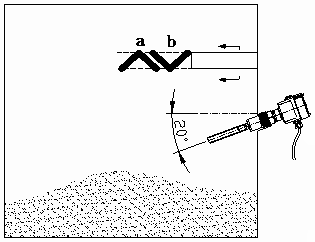

Depending on the site conditions, contact level switches (such as vibrating rod level switches, tuning fork level switches, rotary level switches, radio frequency conductive level switches, etc.) can be installed in a variety of ways, such as top mounted, side mounted, bottom mounted, and used for high level or low level alarms. Side mounting, in order to prevent the probe from being bent or broken by the falling material, and to prevent the probe from hanging material, it is best to use a downward tilt of 20 ° installation, and at the same time, install a protective baffle on the top of the probe in order to achieve the best results.

According to the different characteristics of the materials on site (such as material roughness, particle size, media hardness, etc.), the shape of the protective baffle, usually positive V-shaped, inverted V-shaped, arc, flat plate and so on. In practical application, positive V-shaped, inverted V-shaped protection baffle of these two kinds of protection effect is better, by the user is also relatively more.

Schematic diagram of baffle type installation

a- Inverted V b- Positive V

I. Positive V-shaped protective baffle

Positive V-shaped protective baffle, also called concave protective baffle. This kind of baffle can let the materials form a certain accumulation in the groove, and through this accumulation of materials to form the mutual impact and abrasion between the materials, so as to reduce the impact and abrasion of the materials on the baffle, and improve the service life of the protective baffle. Positive V-type protective baffle is mainly applicable to the measurement of materials with rough surface, high hardness and strong impact and abrasion (such as small gravel, glass slag, small steel slag and other media with high density and rough surface), see "b" in the above figure.

Second, inverted V-type protective baffle

Inverted V-type protective baffle is also called convex protective baffle. When the material falls to the baffle, the material slides down the baffle from both sides of the baffle, so that the probe of the material level switch avoids the direct impact of the material. As the protective baffle is subject to the direct impact of the material for a long time, it is only suitable for media with small abrasiveness, smooth surface and small hardness. It is only suitable for general granular materials or powders (e.g. wheat, rice, fly ash, flour, etc.) with low density, see "a" in the picture above.

Due to the different working conditions in the industrial field, before the installation of the instrument, it should be based on the size of the medium, the roughness and density of the medium, the location of the discharge port and other specific conditions, choose the appropriate installation method to increase the service life of the instrument while preventing the occurrence of false alarms, so as to make the instrument to achieve the best use of the results.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist