BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Familiar with the working principle and advantages and disadvantages of different radar liquid level sensors, helps to help us choose a more suitable level sensor, the following is the detection principle of the current common liquid level sensor.

1 laser level sensor

Laser level sensor is a non-contact high-precision liquid level sensor its performance is very good. It is very similar to the working principle of ultrasonic level sensors, just replace the ultrasonic waves with light waves. The laser beam is very fine, even if the liquid level surface is extremely rough, it can also work normally, laser level sensor can receive a very wide range of general laser level sensor using near infrared light. It is processed by utilizing a semi-transmissive reflector to process the laser light emitted by the optical stream. A part of the reference signal is input into the time transmitter, and the other part of the laser light through the semi-transmissive reflector is processed by the optical system to become a parallel beam of a certain width and irradiated on the object surface. The reflected wave reaches the sensor receiving section and is converted into an electrical signal. Because the time from irradiation to reception is very short, the sampling circuit is utilized to expand it to the order of milliseconds, which facilitates signal processing and time measurement. Using a microcomputer for data processing, into a digital display of the level value of the analog output signal, and then use the software to detect the reliability of the signal, if the measurement system is faulty then the alarm. This sensor is suitable for lakes, rivers, reservoirs, nullahs, tides, urban hydrological water level monitoring field.

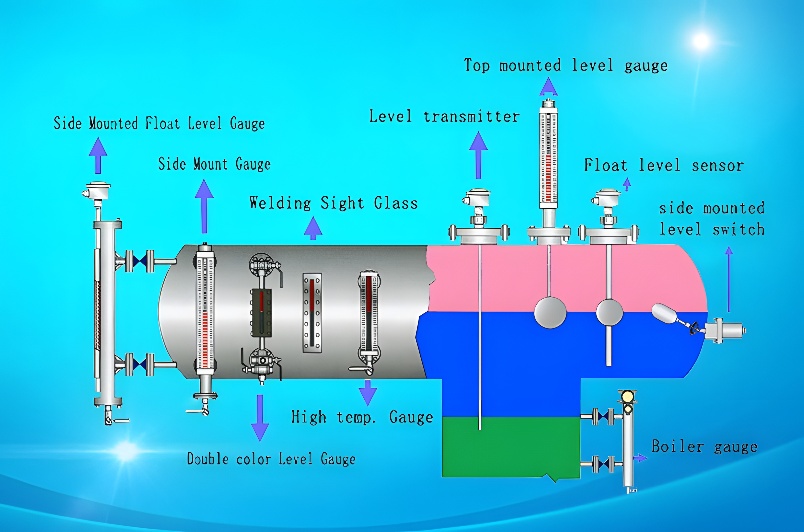

Radar level sensor, with the same advantages as the laser measurement principle, and is not subject to the influence of the measurement medium, less affected by the external environment, no need to repeat the calibration, but the height of the measurement is generally within 6 meters, especially suitable for large containers with heated steam tank measurement, such as residual oil, asphalt and other monitoring areas.

3 ultrasonic level sensor

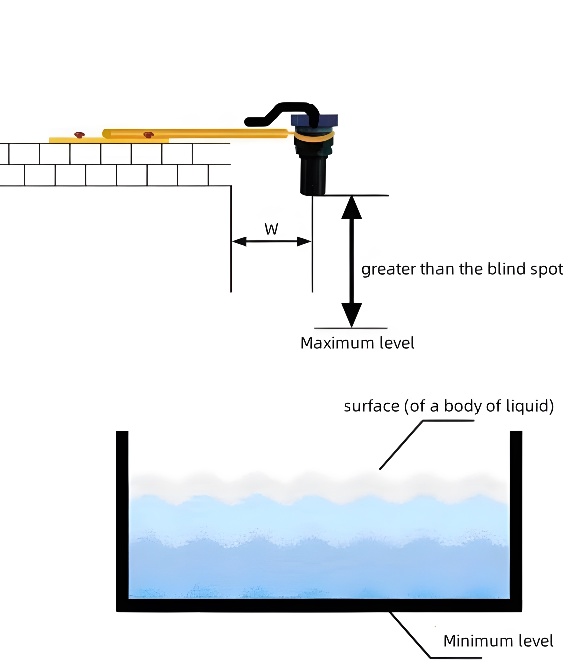

Ultrasonic level sensor, the principle is to monitor the ultrasonic transmission and reflection of the time difference to calculate the height of the liquid level, simple installation, high flexibility, but easy to be affected by the ultrasonic propagation of energy loss, is not applicable to wave-absorbing environments, such as foam, dust, steam and other monitoring areas.

4 Hydrostatic Level Sensors

Hydrostatic level sensor, the measurement principle is to install a pressure sensor at the bottom of the pressure value. Calculation is converted to liquid level height, the advantage is that it does not receive the influence of the liquid level height, but the higher the height, the higher the accuracy of the required level sensor, long time use or replacement of the liquid needs to be calibrated. Widely used in urban water supply and drainage, sewage treatment, reservoirs, rivers, oceans and other monitoring fields.

5 Float Level Sensor

Float type liquid level sensor, through the rise and fall of the float to measure the change of liquid level, mechanical detection, repeatability is poor, not suitable for viscous or impurity-containing liquids, easy to cause float blockage. Float level sensors have a wide range of applications and economical and practical, commonly used in catchment pits, fire ponds, sewage treatment and other monitoring areas, not applicable to the food hygiene industry monitoring areas.

6 tuning fork vibration level switch

Tuning fork vibration level switch, widely used in industrial control systems, applicable to almost all liquid monitoring field. For example, factory coolant tanks and lubricant tanks and other liquid

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist