BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

What is a sensor?

A sensor is a device capable of sensing a specified physical or chemical quantity and converting it into a usable signal

Sensors play a vital role in many fields, whether in industrial production, healthcare, or environmental protection.

At the same time, the sensor is an indispensable device in industrial automation equipment, it is the link between the mechanical system and control system of the equipment.

Mechanical system through the level sensor will motion parameters and operating state feedback to the control system, the control system through the sensor feedback signals and data to send commands to drive the mechanical system, its importance is self-evident.

Sensors are equivalent to the human body's various sensory organs, equipment control systems need to determine through it: the position of the mechanism, the presence or absence of the product, as well as the accuracy of the product and other important parameters in order to monitor and control the use of equipment and the production process of the product.

Classification of Sensors:Sensors can be classified according to the different ways of use, detection methods, and types of output models.

(1) According to its use, the most common main uses of sensors in industrial automation equipment are as follows: detecting the presence or absence, detecting the position, detecting the shape, detecting the speed, detecting the temperature and other physical quantities.

(2) According to its detection method, the following sensors are commonly used in industrial automation equipment: magnetic switches, proximity switches, photoelectric switches, fibre optic sensors.(Fibre-optic sensor is a new type of sensor gradually formed along with the development of optical fibre and optical fibre communication technology. Fiber-optic sensors corrosion resistance, small effect on the medium, has a strong resistance to electromagnetic interference, compared with the traditional types of sensors, fibre-optic sensors with light as a sensitive information carrier, using optical fibers as a medium for transmitting sensitive information with optical fibers and optical measurement characteristics, this new technology in recent years in our country in a number of fields has been widely used)Optical encoders, displacement sensors, low cost pressure sensors, thermocouples, laser sensors, encoders, etc.

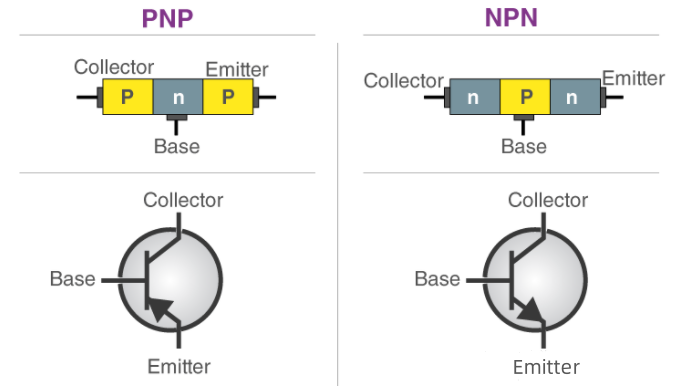

(3) Sensors can be broadly classified into three types depending on the type of output model: switching output type, analogue output type and digital output type. There are two types of sensors with switching output: a normally open type (NO) and a normally closed type (NC). Three-wire system for switching output(Three-wire sensors are those where the positive side of the power supply and the positive side of the signal output are separate, but they share a common COM terminal.)Sensors usually have two types of outputs: NPN and PNP, i.e., low level outputs and high level outputs. Normally, the input/output interfaces of the controllers we use - PLC interfaces or input/output card interfaces of industrial control computers - accept NPN-type output signals. However, NPN and PNP outputs can also be converted to each other by means of relays.

Sensor selection: for the selection of sensors, we just need to understand its purpose can be, do not have to look deeply into the principle of the sensor, usually we need to consider the following three main issues

(1) Testing requirements and conditions,Measurement of target traits, purpose of measurement, range of target values to be measured, frequency of measurement, etc.

(2) Sensor performance, Sensor detection accuracy, response speed, output signal type, etc.

(3) Working conditions,This mainly refers to the environment in which the sensor is used, the environment in which it is connected to other devices, etc.

In addition to considering the three main issues above, there is also a need to consider the followingReliability and longevity of the sensor.The reliability of the sensor determines its stability and accuracy over long periods of operation, while longevity directly affects the maintenance intervals and overall cost of the equipment. In addition, the maintainability and troubleshooting capabilities of the sensor are also important considerations in the selection process, as these characteristics can significantly affect the operational efficiency and maintenance costs of the equipment. Therefore, during the sensor selection process, it is important to not only meet the needs of the current application, but also to consider its performance over the entire equipment life cycle.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist