BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Before we get into secondary instrumentation, let's figure out what primary instrumentation is.

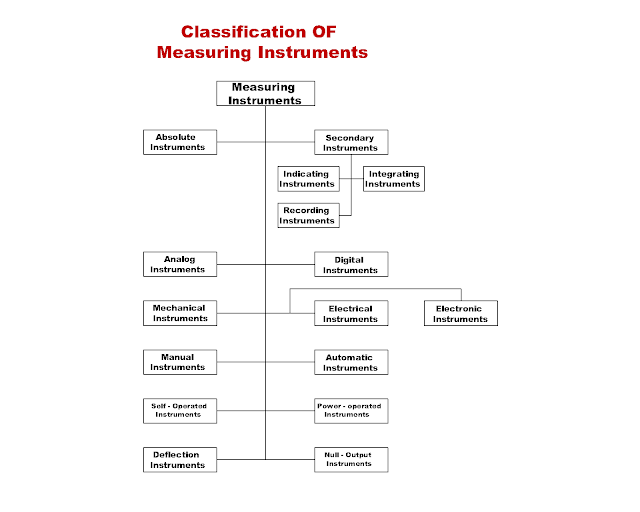

Primary and Secondary Instrumentation Classification Chart

Primary instrumentation usually refers to the sensor, used to directly measure the parameters of the object being measured, such as pressure, level, flow, temperature, etc., and converted into measurable signals or standard signals, these signals usually include electrical signals, pneumatic signals, hydraulic signals, etc., and then transmitted to the subsequent instrumentation for further analysis and processing, display and recording, etc., where the subsequent instrumentation refers to the secondary instrumentation.

It can be seen that the role of the secondary level instrumentation is mainly used to receive the primary instrumentation output signals, the signal characterization of the measurement parameters for the visual indication of digital, analog or other forms of display, and record and analyze the processing, or according to the preset value of the process parameters to be adjusted.

Primary instrumentation is installed directly on the process piping or equipment or installed near the measurement point but in contact with the measured medium, measuring and displaying process parameters or sending parameter signals to secondary instrumentation.

Secondary instrumentation is usually installed in the process pipeline or equipment away from the control panel or instrument panel, they are not in direct contact with the measured medium.

The signals output from the secondary instrument are further processed, displayed or recorded, usually with high indication accuracy and stability, providing more accurate and clearer measurement results, and allowing for multiple forms of display and recording. Secondary instrumentation usually requires a power supply as a driving force to receive signals from the output of the primary instrument. As an important part of automatic detection devices, secondary instruments are widely used in industrial automation, process control, environmental monitoring and other fields. It is of great significance for improving production efficiency, ensuring product quality and realizing automation control.

Secondary instrumentation is one of the components of an automatic testing device, and together with the primary instrumentation forms a complete measurement system. There are many different types of secondary instruments, each with a specific function and purpose.

Below are some common secondary meters:

Display Meter:

Indicators: Indicators, such as those found in motorized unit combinations, are used to display measured values.

Recorders: These include paper and paperless recorders, which are used to record and save measurement data.

Accumulation meters:

Flow totalizers: for measuring and totalizing the flow of fluids.

Electrical energy accumulators: for measuring and totalizing electrical energy consumption.

Control Instrumentation:

Regulator: Outputs control signals to regulate process parameters based on deviations from set and measured values.

Programmable logic controller (PLC): used to realize complex control logic and sequence control.

Signal Conversion Instruments:

Transmitters: Convert measured values to standard signals (e.g. 420mA or 010V) for remote transmission and processing.

Converters: Used to convert one signal type to another, e.g. voltage/current converters, frequency/voltage converters, etc.

Analyzing Instruments:

On-line analyzers: Used for real-time monitoring of a component or property in a process medium.

Laboratory analyzers: for accurate analysis and measurement in a laboratory environment.

Alarm and safety instruments:

Alarms: Signal an alarm when the measured value is out of the set range.

Safety Instrumented System (SIS): Used to monitor and protect the safety of the production process and automatically take action when a dangerous situation is detected.

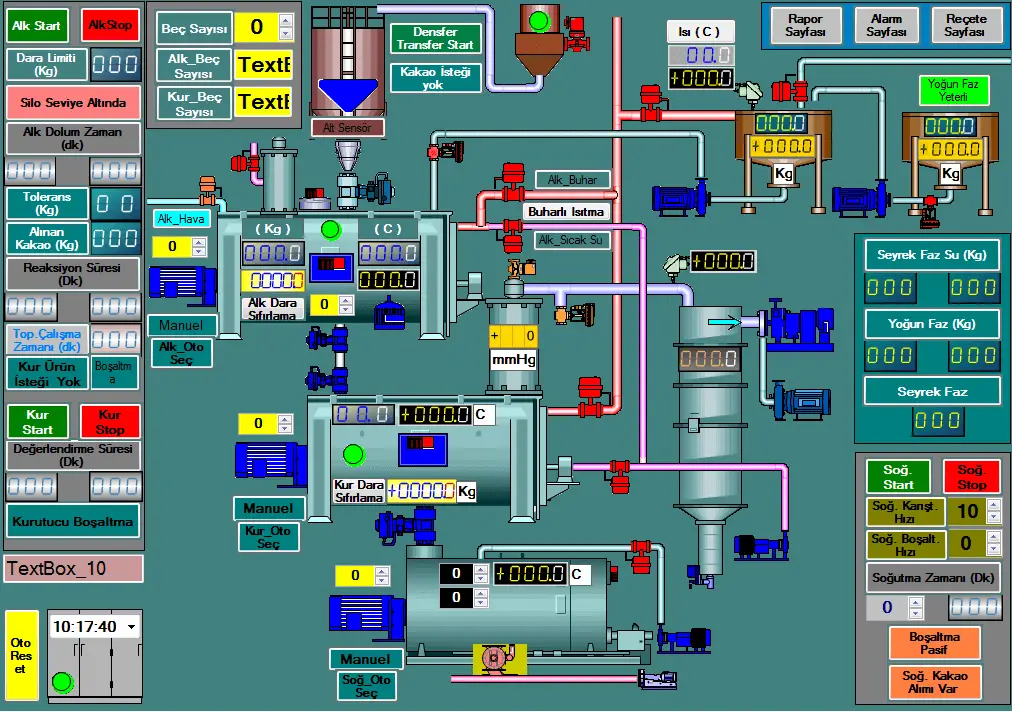

Data acquisition and monitoring system (SCADA):

SCADA system: It is used for real-time collection, processing, display and storage of various data from the field, and realizes remote monitoring and control of the production process.

Data Acquisition and Monitoring System (SCADA)

Other types of secondary instruments:

Calculator: A meter used to perform mathematical operations.

Power Factor Meter: Used to measure the power factor of an electrical system.

Frequency Meter: Used to measure the frequency of alternating current.

Synchronization Indicator: Used to indicate the synchronization of two generators.

Power Meter: Used to measure the power in an AC circuit.

These secondary meters play an important role in industrial automation, process control, environmental monitoring, laboratory analysis and other fields. Selecting and using the right secondary instrumentation is essential to ensure the stability and safety of the production process.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist