BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Level measurement instruments is an important process parameter in the chemical industry, involving productivity, safety, cost and risk. However, chemical media are often highly corrosive, which brings great challenges to level measurement. How to choose the right level meter for strongly corrosive chemical materials and use and maintain it correctly is the issue to be discussed in this paper.

First of all, we need to understand the main principles and types of strong corrosive chemical material level meter. At present, the following types of strong corrosive chemical level meters are common in the market:

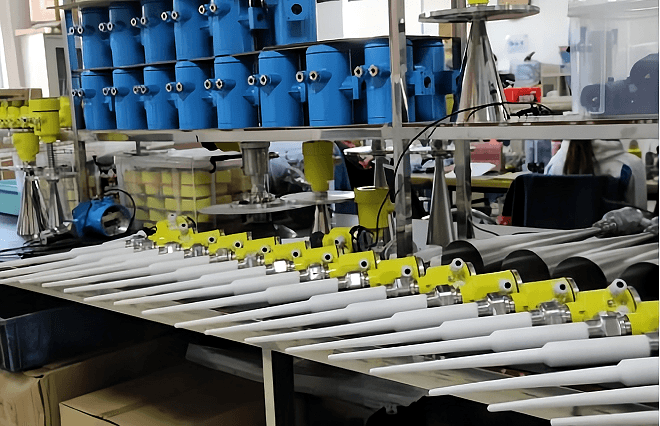

Radar Level Gauge: Using the reflection of microwave signals between air and medium, the liquid level height is calculated according to the change of flight time and frequency of microwave signals. Radar level meter has the advantages of anti-interference, anti-condensation, anti-hanging material, etc. It is suitable for containers of various shapes and materials, as well as a variety of liquid and solid media.

Ultrasonic level meter: Using ultrasonic transmitter to transmit ultrasonic signals to the medium, according to the reflection of ultrasonic signals between the air and the medium, as well as ultrasonic signals of the flight time, the liquid level height is calculated. Ultrasonic level meter has the advantages of simple installation, easy maintenance, low cost, etc. It is suitable for liquid level measurement in various industrial fields.

Secondly, we need to master the selection points of the strong corrosive chemical material level meter. When selecting the type, the following factors need to be considered:

Physical and chemical properties of the medium: such as density, viscosity, dielectric constant, temperature, pressure, corrosivity, etc..

The shape and size of the vessel: such as diameter, height, opening mode, etc.

Conditions of the measurement environment: e.g. dust, gas, humidity, temperature difference, etc.

Precision and range of measurement requirements: e.g. resolution, repeatability, stability, etc.

Ease of installation and maintenance: such as installation location, installation mode, power supply, signal output, etc.

Finally, we should pay attention to the use and maintenance methods of the strong corrosive chemical material level meter. When using and maintaining, you need to pay attention to the following points:

Before installation, check whether the meter is intact and undamaged, whether it is consistent with the selection, whether there are explosion-proof requirements and so on.

When installing, operate according to the instruction manual or the guidance of the technician to ensure that the connection between the meter and the container is firm and reliable, and avoid the phenomenon of air or liquid leakage.

Parameter settings should be made according to the actual situation when commissioning, such as zero calibration, full scale calibration, sensitivity adjustment, etc.

When using the instrument, check the working status of the instrument regularly, such as whether the display is normal, whether there is any abnormal alarm, whether it is necessary to clean or replace parts.

Maintenance should be in accordance with the instructions or the guidance of technical personnel, such as power off or cut off the signal line before disassembling the meter, use the appropriate tools and cleaning agents to avoid damage to the meter or affect the accuracy of measurement.

Strong corrosive chemical material level meter is an indispensable instrument in the chemical industry, which can effectively improve production efficiency and safety, reduce costs and risks. Choosing the right level meter for strong corrosive chemicals and installing, using and maintaining it correctly are the key to ensure the long-term stable operation of the meter.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist