BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

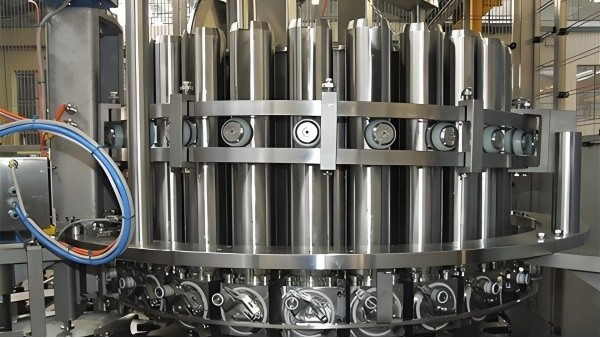

With the rapid development of industrial automation technology, rotary filling system, as one of the key technologies to improve production efficiency and product quality, has been widely used in food, pharmaceutical and cosmetic industries. However, in the high-speed continuous production process, how to accurately and real-time monitoring and management of material level changes, to ensure filling accuracy and efficiency, has become a major challenge for the industry. In this paper, the innovative application of 80G radar level meter in rotary filling system will be discussed in depth.

Rotary filling system occupies an important position in the field of packaging of liquid, semi-fluid and some solid materials with its high efficiency and precision. The system realizes simultaneous filling of multiple containers or bottles by continuous rotation, which greatly enhances the production efficiency. However, level control of the material is critical in this process. Too high a level may lead to overflow and waste, while too low a level may affect filling accuracy or even cause flow breakage. Therefore, real-time and accurate monitoring of level changes is essential to ensure the stable operation of the filling system.

As an advanced level measuring instrument, 80G radar level meter shows excellent performance in many industrial fields with its features of high accuracy and non-contact measurement. It adopts FMCW (Frequency Modulated Continuous Wave) technology to accurately calculate the level height by transmitting high-frequency electromagnetic wave and receiving the echo signal. Compared with traditional level meters, 80G radar level meter has the following significant advantages: up to ± 1mm measurement accuracy, to meet the rotary filling system for high-precision level control needs. Avoiding direct contact with materials, reducing the risk of contamination, especially suitable for food, pharmaceutical and other industries with high hygiene requirements. 80GHz high-frequency electromagnetic wave has a strong penetration ability, and can maintain stable measurement performance in different media, even in the steam, foam and other complex environments can also be measured accurately. Simple structure and compact size make it easy to install in narrow space. At the same time, its non-contact measurement characteristics also reduce the difficulty and cost of maintenance.

In the rotary filling system, 80G radar level meter is skillfully integrated in the top of the filling pipeline or storage tank to monitor the level change of the material in real time through its high precision measurement capability. In specific applications, the 80G radar level meter is seamlessly integrated with the PLC system to form a closed-loop control system. When the level reaches the preset threshold, the radar level meter immediately sends a signal to the PLC, which quickly responds by adjusting the filling speed or stopping the filling to ensure that the material level is always maintained in the best state. This intelligent control greatly improves the precision and efficiency of filling, reduces material waste and production costs. 80G radar level meter in the rotary filling system in the innovative application, not only solves the traditional way of measuring the level of many pain points, but also the industrial production has brought unprecedented high efficiency and high precision!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist