BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

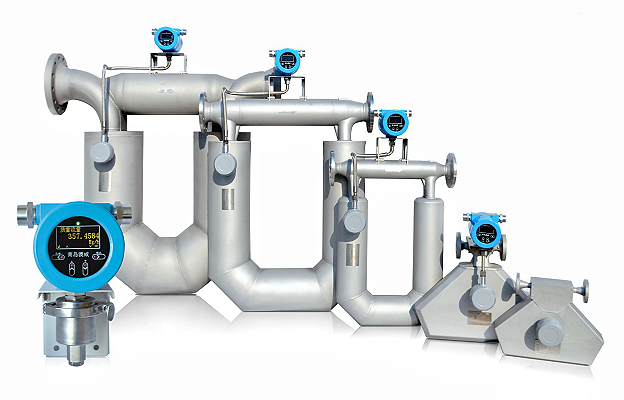

I. Installation of mass flow meters

1. Mass flow meter is through the vibration of the sensor to achieve the measurement, in order to prevent external interference, the instrument installation site can not have a large source of vibration, and take reinforcement measures to stabilize the instrument near the pipeline.

2. Mass flow meter work to use the excitation of the magnetic field, so it can not be installed in large transformers, motors, pumps and other equipment to produce a large magnetic field near, at least and they have to maintain a distance of 0.6 ~ 1.0m or more, in order to avoid interference.

3. Mass flow meter sensor and pipeline connection should not be stress (mainly torque), for this reason, the sensor should be in a free state coal connected to the pipeline has been well supported.

4 straight pipe mass flow meter is best installed vertically, so that the instrument can be deactivated to make the measurement of pipeline emptying, so as to avoid scaling, if installed horizontally, it is necessary to two measurement pipe at the same level.

5. Bend flowmeter horizontal installation, if the measurement of liquid, the shell should be facing down to avoid the accumulation of gas in the measurement tube, if the measurement of gas, the shell should be facing up to avoid the accumulation of condensate measurement tube.

6. Sensor and transmitter connection cable should be specified in the manual, because the transmitter accepts low-level signals, so it can not be too long, and should use the thermal mass flow meter manufacturer's special cable.

II. Routine maintenance of the mass flow meter

1. Zero check and adjustment.

Check every two to three months, in the case of production allows, the installation of important monitoring points in the quality of the flowmeter, the zero check time should be appropriately shortened zero drift value is large, should first check the cause, to be ruled out, and then zero point adjustment.

2. Flowmeter sealing performance inspection and maintenance

Flowmeter in corrosive gases, humidity or dusty environment, we should always pay attention to check the sensor junction seal intact, in order to prevent corrosion of the terminals, resulting in the instrument can not operate normally!

3. Check the working parameters

a. Often pay attention to whether the set operating parameters have changed, the display of the flow rate, density, temperature value is normal

b. When the flow meter is running, pay attention to check the pressure difference before and after the flow meter.

c. Check the flow transmitter menu at any time whether the working parameters are normal

4. Regularly observe the flowmeter fault indication.

According to the type of flowmeter, specifications, thermal mass flow meter manufacturers of different fault display and content are different, the different fault alarm instructions, you can check the product manual to determine the cause of the failure, processing.

5. Flowmeter cycle calibration.

Flowmeter use for a period of time, according to the requirements of the periodic calibration, in order to determine the performance of the flowmeter, according to the quality of the flowmeter national calibration procedures, the quality of the flowmeter calibration cycle according to the use of the situation is determined

6. flowmeter visual inspection

Check the meter indication, whether the cumulative value is consistent, sweep away the dust and dirt, instrumentation, electrical junction box and component box sealing is good, flowmeter line with or without damage and corrosion, flowmeter meter body and connectors with or without damage and corrosion, check the flowmeter and the process piping connection with or without leakage, check the heat preservation and accompanying heat with or without damage.

III. Mass Flow Meter Common Failures

hardware failure

This kind of failure is more harmful, and not easy to judge, it is more complicated to deal with.

a. Installation is not standardized: non-standard installation can directly lead to zero drift of the flowmeter, bringing measurement error; if the installation error is the flowmeter can not work. b. Wiring problems: when the wiring is wrong, the transmitter can not work.

b. Wiring problems: wiring errors when the transmitter can not work. If the wiring is not serious, resulting in coil circuit resistance value is too large or too small, the lesser brought about by the measurement error, the heavier the transmitter can not work.

c. Changes in the process medium: If the measurement medium appears to be trapped gas, gasification or two-phase flow and other phenomena, the transmitter will send out an alarm; serious transmitter stop working.

d. Transmitter failure: a part of the transmitter device failure may lead to transmitter zero drift over the limit to bring the measurement error; or a part of the device failure, resulting in transmitter failure can not work; or some kind of functional failure of the transmitter. This type of failure can be simply judged by replacing the transmitter.

e. Sensor failure: sensor measurement tube if leakage, the measurement medium will be filled with the case leading to the measurement tube vibration damping increases, the transmitter drive voltage soars; or the medium temperature is too high, damage to the measurement tube on the coil, resulting in drive, detection voltage imbalance. This type of failure is the most difficult to judge, because it rarely occurs, and the transmitter does not correspond to the alarm information, can only be based on experience and a combination of factors to determine.

software failure

a. Wrong parameter settings: incorrect flow and density coefficients are bound to cause measurement errors; if the coefficient of difference is too large, the transmitter alarm and stop working.

b. Zero calibration error: flowmeter installation (including new installation and removal and reinstallation) must be strictly in accordance with the requirements of the zero calibration, otherwise it will cause errors; long-term operation of the flowmeter has not been disassembled should also be zero calibration on a regular basis in order to eliminate the cumulative effect of the installation of stress. Special attention should be paid to, if there is a flow of zero calibration, it is possible to destroy some of the memory parameters. c. I / O configuration error: I / O (input / output) is wrong, the flowmeter system can work normally, but the secondary table is displayed abnormally. If the output adopts frequency signal, the pulse equivalent of both ends should be the same; if RS-485 communication is used, the communication protocol should be ensured.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist