BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

In modern industry, accurate liquid level measurement is crucial, especially in industries such as chemicals, petroleum, and food. Magnetic flip-type liquid level gauges, with their unique working principle and numerous advantages, have become the ideal choice for liquid level measurement.

Working Principle

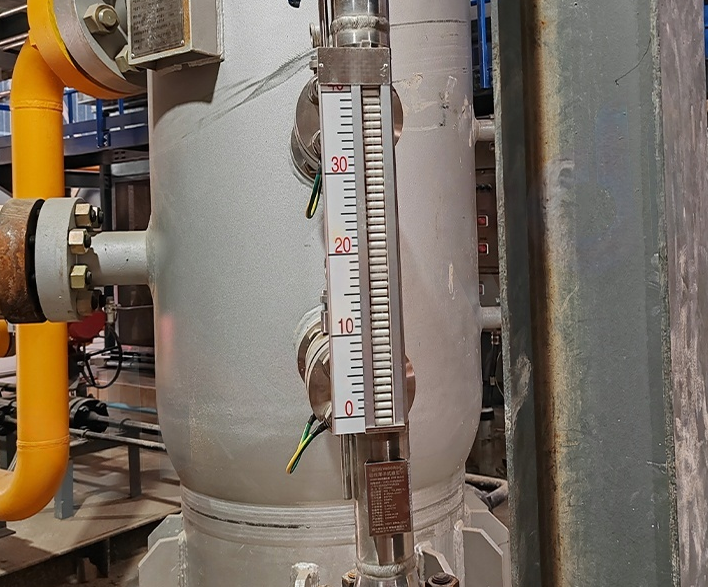

The magnetic flip-type level gauge mainly consists of a magnetic flip plate, a level gauge body, and a float ball. The float ball floats up and down with changes in the liquid level, and the built-in magnetic elements drive the flip plate to rotate, indicating the height of the liquid level. This non-contact measurement method not only improves measurement accuracy but also reduces the risk of failure.

Advantage Analysis

High reliability: With no electrical components, magnetic flip-type level gauges perform well in extreme environments, require low maintenance, and have a long service life.

Corrosion resistance: The device can adapt to a variety of chemical media, demonstrating strong resistance, especially when handling corrosive liquids.

Visual indication: The intuitive display of the flip-type gauge allows operators to quickly obtain level information, simplifying the monitoring process.

High adaptability: Whether in high-temperature or high-pressure environments, magnetic flip-type level gauges operate stably, ensuring safety.

High safety: The design without electrical components reduces the risk of explosion in hazardous environments, making it the preferred choice for many industries.

Application Areas

Magnetic flip-type level gauges are widely used in reactors, storage tanks, boilers, and other applications, particularly suitable for situations requiring precise monitoring and control of liquid levels. Whether in chemical reactions, liquid storage, or food processing, magnetic flip-type level gauges play an indispensable role.

Conclusion

In summary, magnetic flip-plate level gauges have become an important tool in the field of level measurement due to their unique working principle and significant advantages. With the continuous development of industrial automation, their application is expected to become even more widespread, providing more efficient and safer level monitoring solutions for production processes across various industries.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist