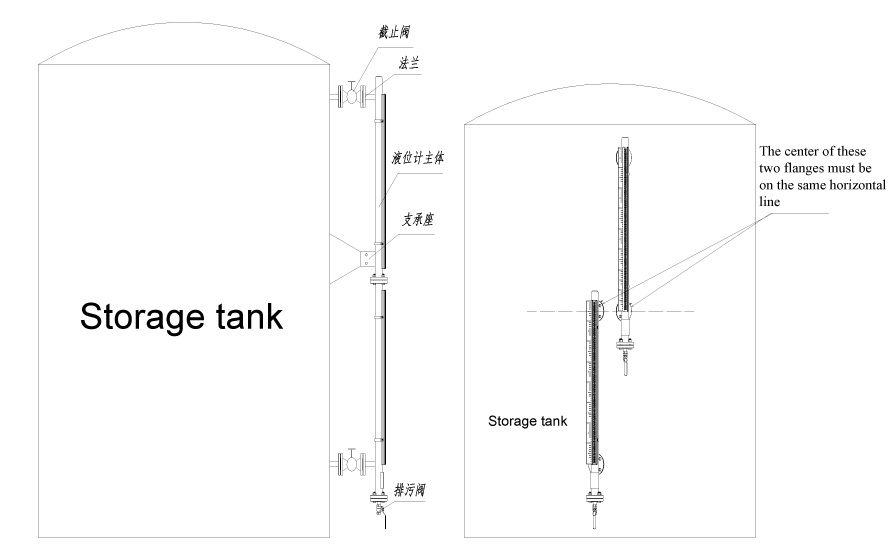

For big size tank. can measing height more than 15 meters

With flanges on both ends, magnetic flap level gauge can be joint together to reach very high measring range.

Max rang can be over 15 meters, for example we can make 3 meter x 5 PCS.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist