1.Product Introduction

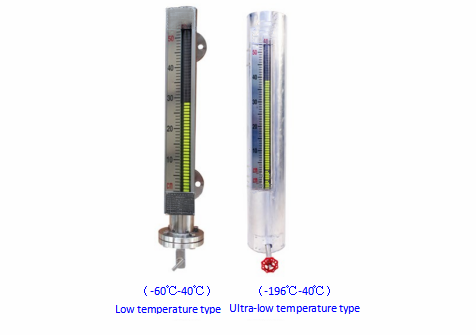

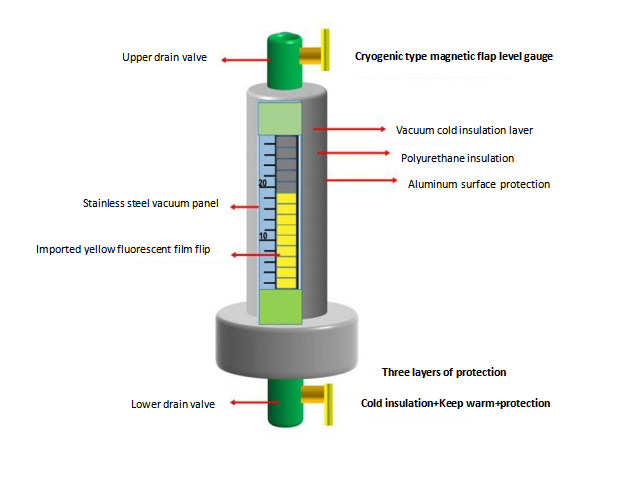

UZC cryogenic magnetic level gauge is suitable for low temperature and ultra-low temperature liquid measurement, the lowest working temperature can reach -196℃. The product chamber adopts the most mature cryogenic isolation technology, which can make the level gauge normal in low temperature environment for a long time. In use, it has the advantages of no frost on the surface, no blind spots in the whole process of measurement, eye-catching display, intuitive reading, and large measurement range. According to the working temperature, it can be divided into: low temperature type and ultra low temperature type. Both of these two liquid level gauges adopt different cryogenic isolation processes to meet the corresponding temperature measurement.

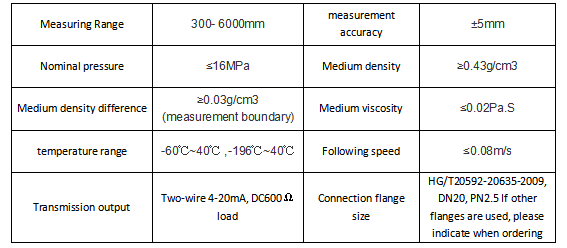

2.Technical Parameter

3.Selection table

Model | illustrate | |||

UZ | Kaidi Magnetic Level Gauge | |||

Type of installation | C | Side loading | D | Top loading |

Panel type | A1 | -40-80℃ normal temperature | Z1 | -190~-20℃ Vacuum |

A2 | 80-180℃ medium temperature | Z2 | -20-180℃ Vacuum | |

A3 | 180-350℃ high temperature | Z3 | Vacuum at 180-350℃ | |

A4 | 350-450℃ ultra high temperature | E | -40℃-450℃ magnetic sensitivity | |

Pressure Rating (MPa) | 1.0 | PN1.0 | 2.0 | CL150LB |

1.6 | PN1.6 | 5.0 | CL300LB | |

2.5 | PN2.5 | 11.0 | CL600LB | |

4 | PN4.0 | 15.0 | CL900LB | |

6.3 | PN6.3 | 26.0 | CL1500LB | |

10 | PN10.0 | 42.0 | CL2500LB | |

16 | PN16.0 | |||

Range-Density | Range mm-density g/cm³ | |||

Flange Material | P | 304 | PF | 304 lined with fluorine |

PL | 316L | C | Carbon steel | |

PP | PP | Ti | titanium | |

Flange Diameter | 15 | Side mounted DN15 | 50 | Top loading DN50 |

20 | Side mounted DN20 | 65 | Top loading DN65 | |

25 | Side mounted DN25 | 80 | Top loading DN80 | |

32 | Side mounted DN32 | 100 | Top loading DN100 | |

40 | Side mounted DN40 | 125 | Top loading DN125 | |

50 | Side mounted DN50 | 150 | Top loading DN150 | |

65 | Side mounted DN65 | 200 | Top loading DN200 | |

80 | Side mounted DN80 | 250 | Top loading DN250 | |

Flange sealing surface | Omit | Raised face | FM | Concave |

F | Convex | FF | Full plane | |

Tube material | P | 304 | P1 | 321 |

PL | 316L | P4 | 304L | |

PF | 304 lined with fluorine | Ti | titanium | |

PP | PP | |||

Insulation/anti-frost | Omit | No | ||

C | Type C insulation pipe (recommended) | |||

T1 | Set vacuum insulation | |||

T2 | Jacket insulation | |||

D1 | 40-90 constant temperature electric heating | |||

D2 | 120°C temperature control adjustable electric heating | |||

S1 | Anti-frost below -40°C | |||

S2 | -40~-20℃ anti-frost | |||

Accessories | Y | Remote transmission level gauge | ||

K | Alarm switch | |||

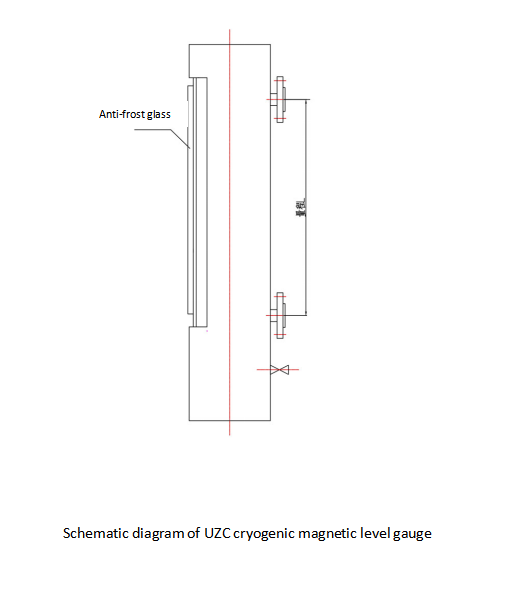

4.Dimensions

5.Product Structure

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist