Product introduction

Ultrasonic level gauge (measuring material level, liquid level) is a non-contact, highly reliable, cost-effective, and easy-to-install and maintain level measuring instrument. It can meet most of the level measurement requirements without contacting the medium. It is a new generation of ultrasonic level meter that our company has developed after years of hard work and has completely independent property rights.

Debugging

Because the installation environment of the instrument is different. Therefore, the ultrasonic level meter must know the basic conditions of the required measurement before working, such as: measuring range, zero point, full range and field conditions, etc. Therefore, the meter must be set up before measurement.

Technical parameters of integrated ultrasonic level gauge

| Structure | One-piece | ||

| Range | 10 meters | Blind area | 0.3-0.4 meters |

| Power supply | 24VDC | Wire system | two-wire system |

| Output | 4-20ma | Connection method | G2 thread |

| Sensor protection level | IP68 | Shell material | ABS |

| Host protection level | IP65 | Medium temperature | -20~+60℃ |

| Medium pressure | normal pressure | Working environment temperature | -20~+60℃ |

Product display diagram

Installation guide

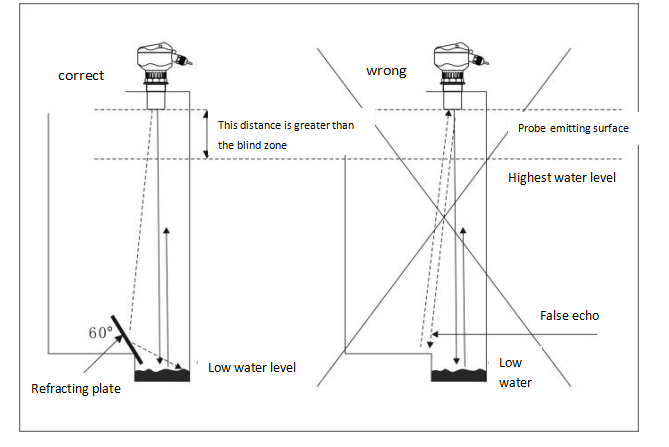

(1)Measuring liquid

In the reservoir, generally speaking, the installation height of the meter should be determined according to the highest water level. You must pay attention to the distance between the highest water level and the probe. When the water level is low, there are objects at the bottom of the pool, and this edge should use a refraction plate. Block.

There is an obstacle at the bottom of the pool-use a baffle to refract

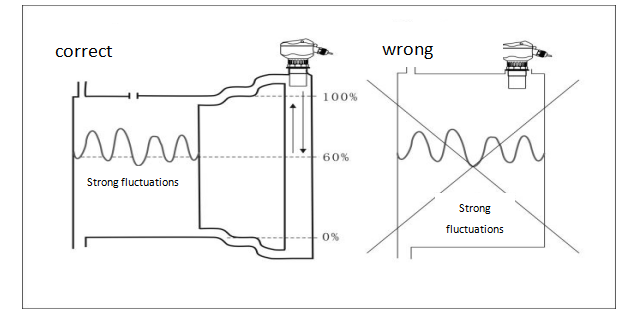

If there is a strong vortex or vortex in the container, such as the vortex caused by a stirrer or a strong chemical reaction, the measurement will be very difficult. The ideal way is: the sensor probe can be installed in the still tube or the bypass tube for measurement.

The surface of the medium fluctuates greatly-use a bypass tube or add a still tube to measure

(2)Common installation errors

①Bubbles:

If the bubbles on the surface of the medium are large and the bubble layer is thick, it will cause measurement errors and even fail to receive the reflected ultrasonic waves. Please take measures to prevent air bubbles, or install the sensor in the bypass pipe for measurement.Other measuring instruments can also be used, such as radar level gauges, magnetostrictive level gauges.

②The sensor is installed in the wrong direction

If the sensor is not mounted on the surface of the medium, the measurement signal will be weakened. To ensure the best measurement effect, please align the axis of the sensor with the surface of the medium, which is perpendicular to the surface of the interface to be measured.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist