The extremely narrow microwave pulse emitted by the antenna on radar level instrument can travel at the speed of light and part of its energy.which is reflected off the surface of target medium, is received by the very same antenna.The time lapse between pulse emission and reception by the antenna is proportional to the distance between the surface of target medium and the reference point on antenna.However。due to the fact that the electromagnetic wave is Transmitted at extremely high speed.which leads to the tiny time lapse (nanosecond level) and makes it difficult to be identified.GDRD5×series of radar level instrument have adopted a special demodulation technology.enabling itself to detect the time lapse between pulse emission and reception correctly, and eventually generate accurate measurement result.

The extremely narrow microwave pulse emitted by the antenna on radar level instrument can travel at the speed of light and part of its energy.which is reflected off the surface of target medium, is received by the very same antenna.The time lapse between pulse emission and reception by the antenna is proportional to the distance between the surface of target medium and the reference point on antenna.However。due to the fact that the electromagnetic wave is Transmitted at extremely high speed.which leads to the tiny time lapse (nanosecond level) and makes it difficult to be identified.GDRD5×series of radar level instrument have adopted a special demodulation technology.enabling itself to detect the time lapse between pulse emission and reception correctly, and eventually generate accurate measurement result.

The guided wave radar level instrument, adopted 26GHz as transmitting frequency, which make this series have specialties as below:Small beam angle, which centralize energy, make GDRD5X high ability of anti—jamming, hence high accuracy and reliable.Small antenna size, easy to mount and easy to equip extra dust protection Small blind zone, good accuracy even for small vessels.Shorter wave—length, suitable for small power.

Equipped with advanced microprocessor and unique Echo Discovery echo processing technology, the radar level instrument can be used under various hazardous process conditions.

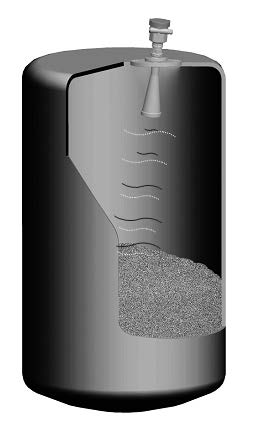

The guided wave radar level instrument, with pulses as its working tool and extremely low emission power, can be mounted on various metal or nonmetal vessels, harmless towards the environment and human beings.

Model | KDZA55 | KDZA56 | KDZA88 |

Application | Liquid | Anti-temperature and anti-pressure, mildly erosive liquid | For solid and powder 5.6KGS DN100 |

Adapt to highly erosive liquids | 30m | 50-70m | |

Range | 10mm:30m(Horn 80mm) | + 3mm | + 3mm |

Accuracy | + 5mm | (-40 - 80) °C | (-40 - 80) °C |

Process Temperature | (-40 - 130) °C | (-40 - 130) °C | (-40 - 130) °C |

(-60 - 250) °C | (-60 - 250) °C | ||

(-60 - 400) °C | (-60 - 400) °C | ||

Normal | Normal | ||

Process Pressure | (-0.1 - 0.3)MPa | (-0.1 - 4)MPa | (-0.1 - 4)MPa |

(-0.1 - 40)MPa | (-0.1 - 40)MPa | ||

26GHZ | 26GHZ | ||

Frequency Range | 26GHZ(4 - 20)mA/HART | (4 - 20)mA/HART | (4 - 20)mA/HART |

Signal Output | Two-wire system (DC24V) | Two-wire system (DC24V) | Two-wire system (DC24V) |

Power | 4 wire system (DC24V/AC220V) | Four-wire system (DC24V/AC220V) | Four-wire system (DC24V/AC220V) |

Optional | Optional | Optional | |

Field Displaying | A/B/C/D (view page 4) | K/B/C/D1 | K/B/C/D1 |

Process Connection | F | C/N/I/J/K2 | C/N/I/J/K2 |

Flange Accessories | L | L/M/N/P3 | L/M/N/P3 |

Antenna | R | S/T/V3 | S/T/V3 |

Frequency Range | Liquid | Anti-temperature and anti- pressure, mildly erosive liquid | Anti-temperature and anti- pressure, mildly erosive liquid |

Model | KDZA57 | KDZA58 | KDZA59 |

Application | liquid | solid | solid |

High corrosive, sanitary | Storage vessel, process vessel, Strong dust, easy to crystallize, condensation | Normal temperature, normal pressure | |

Max. Range | 20m | 70m | l 5m |

Accuracy | +3mm | +1 5mm | +1 0mm |

Temperature | (-40 - 150)°C | (-40 - 80)°C | (-40 - 80)°C |

(-40 - 1 20)°C | (-40 - 1 20)°C | ||

(-60 - 250)°C | (-60 - 250)°C | ||

(-60 - 400)°C | |||

Process Pressure | (-0.1 - 0.5)MPa | normal pressure | normal pressure |

(-0.1 - 4)MPa | (-0.1 - 4)MPa | ||

(-0.1 - 40)MPa | |||

Frequency Range | 26GHZ | 26GHZ | 26GHZ |

Signal Output: | (4 - 20)mA/HART | (4 - 20)mA/HART | (4 - 20)mA/HART |

Power | 2 Wires (DC24V) | 2 Wires (DC24V) | 2 Wires (DC24V) |

4 Wires (DC24V/AC220V) | 4 Wires (DC24V/AC220V) | 4 Wires (DC24V/AC220V) | |

Field Displaying | optional | optional | optional |

Process Connection | A/B/C/D1 | A/B/C/D1 | A/B/C/D1(Page 4) |

Flange Accessories | G/H/I/J/K3 | G/H/I/J/K3 | |

Antenna | U | L/M/N/P3 | L/M/N/P3 |

Frequency Range | S/T/V/W3 | S/T/V/W3 |

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist