Related Products

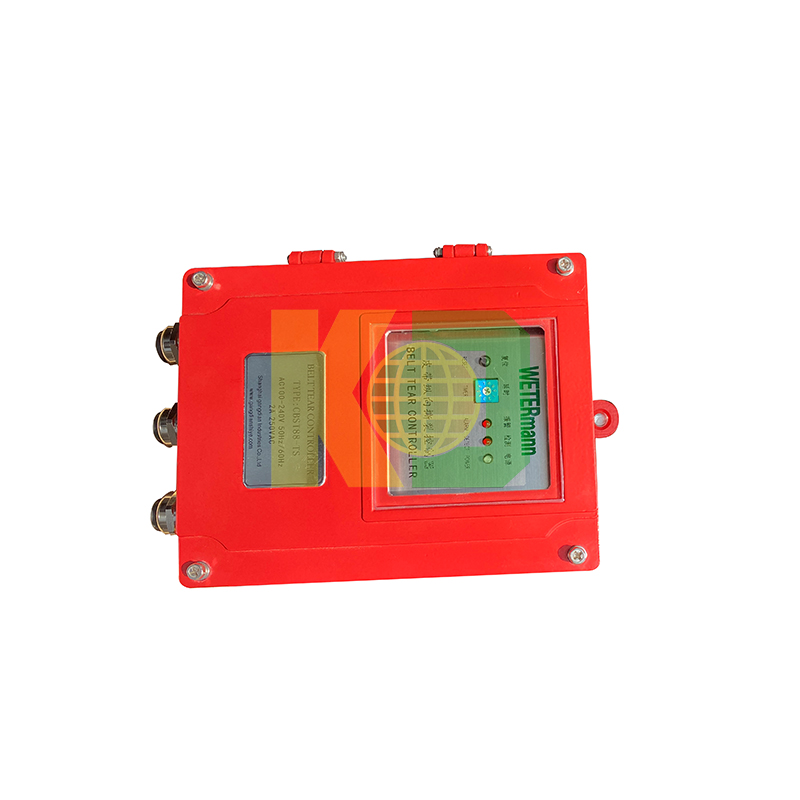

| Protection Grade: | IP65 |

|---|---|

| Process Temperature: | 20℃~+60℃ |

| Contact capacity | 2A 250ACV |

| Power supply | AC 90~245V 50/60Hz |

| Width of belt | No limit |

| Roller groove angle | No limit |

| MOQ | 1 SET |

| Payments: | TT, Paypal, Credit card, Western union |

| Shipping ways: | Express(DHL,Fedex,TNT,EMS,UPS)/Air/Sea |

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist