PRODUCT OVERVIEW

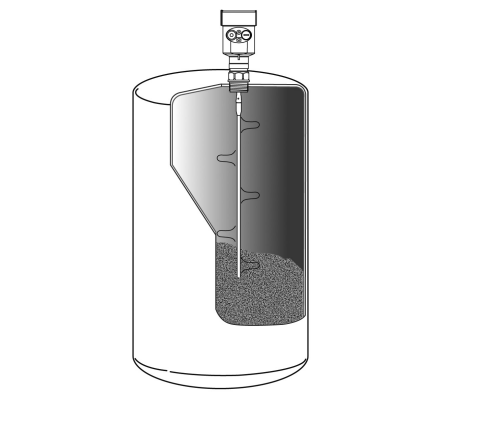

As a result of advanced microprocessor and unique choDiscovery echo processing technology, guided wave radar level meter can be used in a variety of complex conditions.

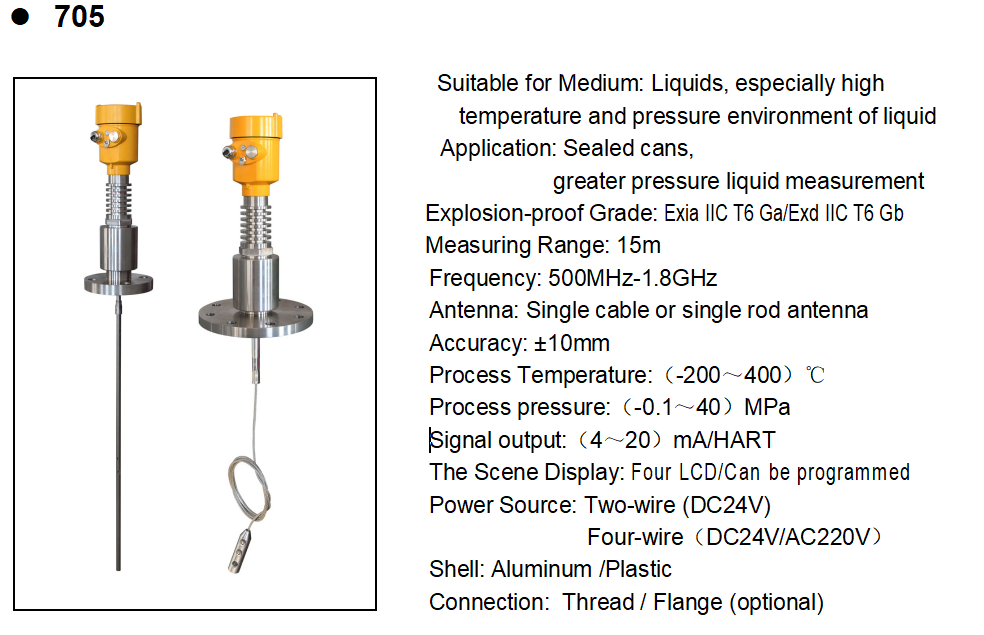

Because of the type of process connections and detection components, making 70X Series Guided Wave Radar Level Meter is suitable for a variety of complex conditions and applications. Such as: high temperature, high pressure and low dielectric constant media.

Pulsed work, guided wave radar level instruments transmit power is very low, can be installed in a variety of metals, non-metallic container, no harm to humans and the environment.

THE PRODUCT PRINCIPLE

High-frequency microwave pulses issued by the guided wave radar propagate along detection components (steel cable or steel rod), met the media to be measured, since the dielectric constant of the mutation, cause reflections, a portion of the pulse energy is reflected back. Transmit pulse and the reflected pulse is proportional to the distance and the time interval measured media.

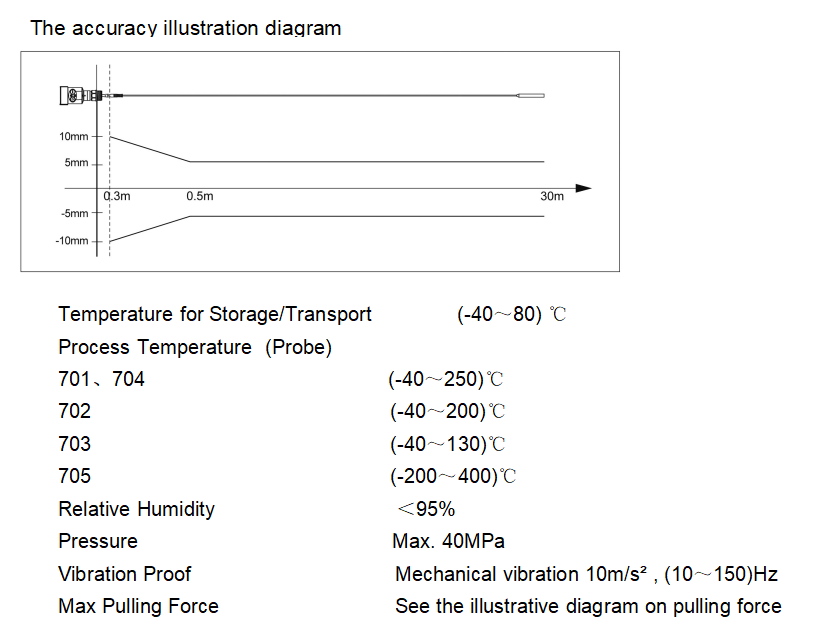

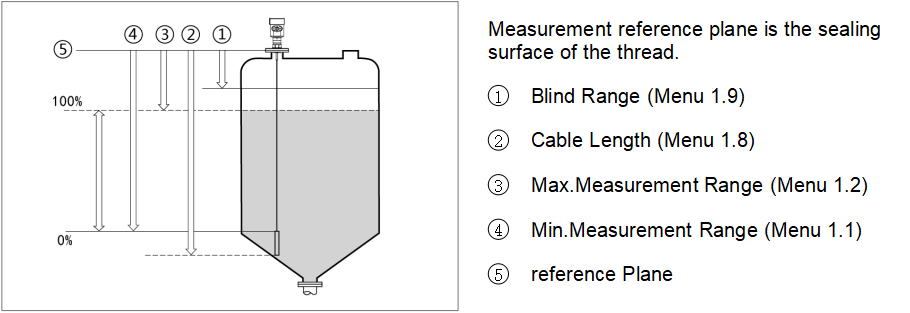

Note: In order to ensure the accuracy of level measurement, the material should be located between the top and bottom of the blind the blind.

Ø Small antenna size, easy to install; Non-contact radar, no wear, no pollution.

Ø Almost no corrosion, bubble effect; almost not affected by water vapor in the atmosphere, the temperature and pressure

changes.

Ø Serious dust environment on the high level meter work has little effect.

Ø A shorter wavelength, the reflection of solid surface inclination is better.

Ø Beam angle is small, the energy is concentrated, can enhance the ability of echo and to avoid interference.

Ø The measuring range is smaller, for a measurement will yield good results.

Ø High signal-to-noise ratio, the level fluctuation state can obtain better performance.

Ø High frequency, measurement of solid and low dielectric constant of the best choice.

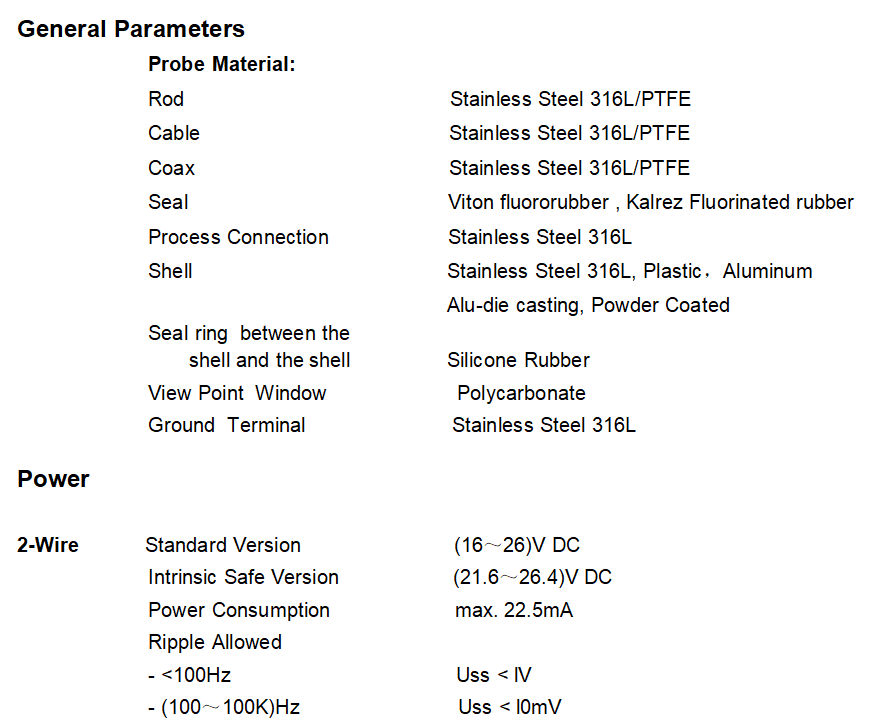

PRODUCT SPECIFICATION

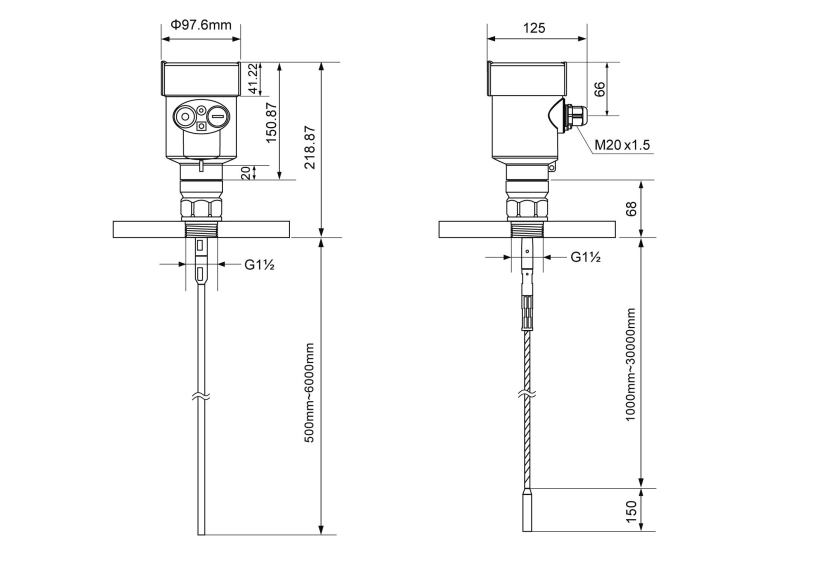

APPEARANCE OF SIZE

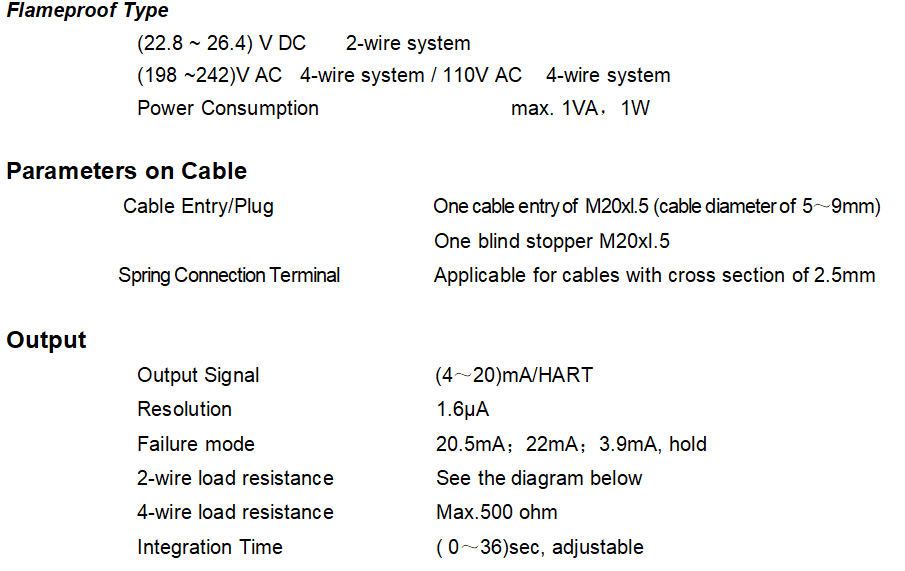

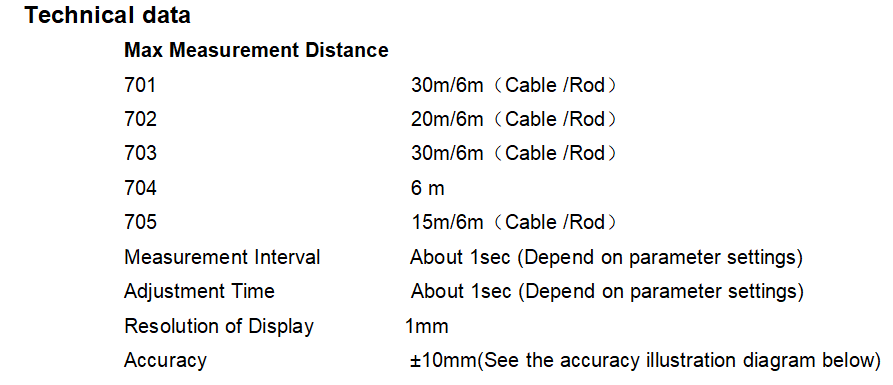

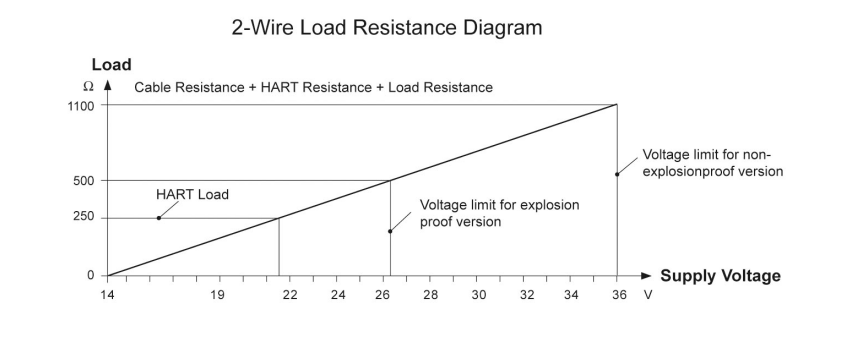

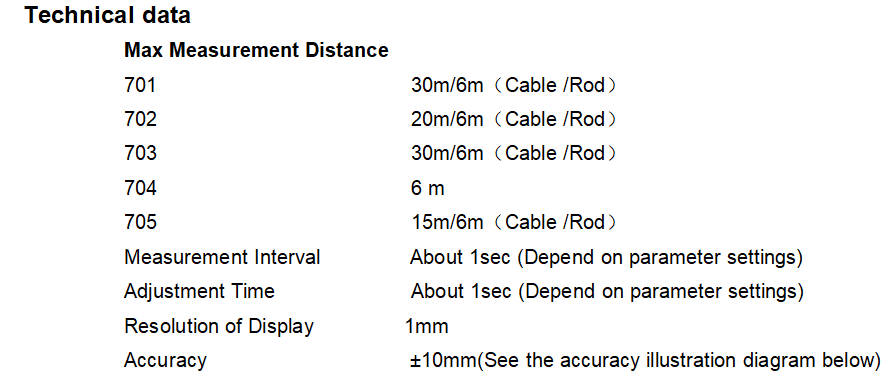

TECHNICAL PARAMETERS

INSTALLATION REQUIREMENTS

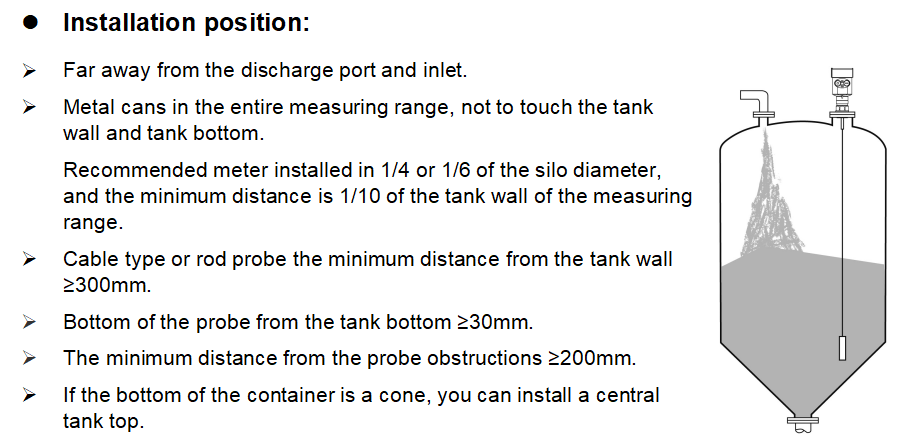

Within the measurement range, determined not to come into contact with the cable or rod internal obstacles, Therefore, the installation should be avoided as far as possible the tank facilities, such as: human ladder, limit switches, heating devices, stand etc. Also note that the cable or rod may not intersect with the material during feeding.

Also note that when installing the meter:Highest Level measurement can not enter into the blind; Must be maintained between the instrument and the tank wall a certain distance; When the meter is installed, try to stick with cable or perpendicular to the surface of the measured medium. Meter installation in hazardous areas must comply with state regulations explosion hazardous installation area. Intrinsically safe instrument requires the use of shell with aluminum. Intrinsically safe instrument can be installed in explosion-proof requirements of the occasion, the instrument must be connected to the earth.

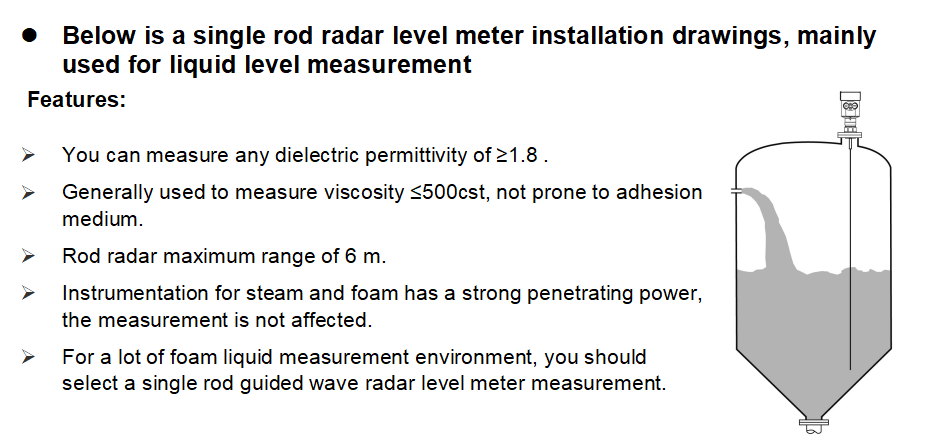

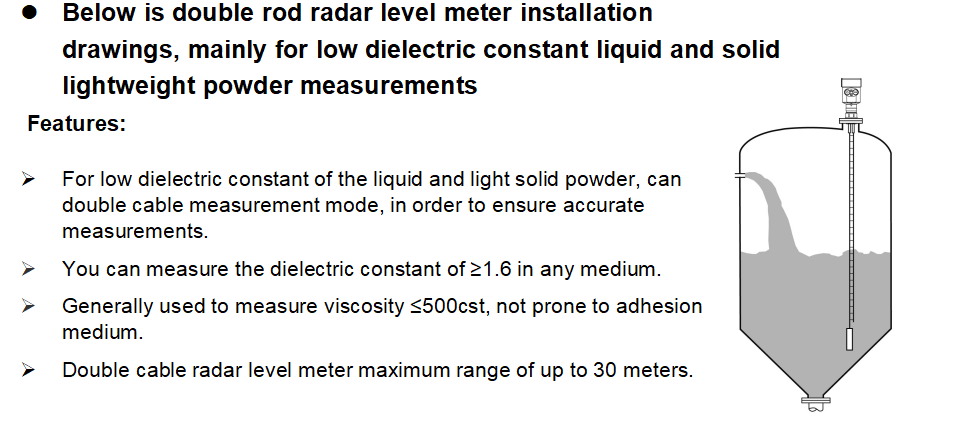

The following guidelines apply to the installation of the cable and the rod radar level measuring solid powder or liquid.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist