BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Level measuring instruments are industrial automation instruments that measure the level and loading height of liquid and powdery materials.

Measurement of lumps, particles and powders and other solid materials, such as the height of the accumulation, or the surface position of the instrument is called material level meter; measurement of tanks, towers and tanks and other containers within the height of the liquid, or the liquid surface position of the instrument is called the liquid level meter, also known as the liquid level meter; measurement of containers in the two insoluble liquids or solids and liquids in the phase of the interface position of the instrument is known as the phase interface meter. So, how to choose the right level meter? Today for you to introduce the specific level instrumentation selection issues, together to understand it!

General Principles

1) should have a thorough understanding of the process conditions, the nature of the measured medium, measurement and control system requirements, in order to make a full evaluation of the instrument's technical performance and economic effects, so that it can play a due role in ensuring production stability, improve product quality, increase economic benefits.

2) liquid level and interface measurement should be used differential pressure instrumentation, float type instrumentation and float type instrumentation. When the requirements are not met, capacitive, resistive (electrical contact), acoustic wave type instruments. Material surface measurement should be based on the particle size of the material, the angle of repose of the material, the conductivity of the material, the structure of the silo form and measurement requirements for selection.

3) The structure of the instrument form and material, should be based on the characteristics of the measured medium to choose. The main considerations are pressure, temperature, corrosivity, electrical conductivity; the existence of polymerisation, viscosity, precipitation, crystallisation, film, gasification, blistering and other phenomena; density and density changes; the liquid contains the amount of suspended matter; the degree of liquid surface disturbance and the particle size of solid materials.

4) The display mode and function of the instrument should be determined according to the requirements of process operation and system composition. When the requirements of signal transmission, can choose to have analogue signal output function or digital signal output function of the instrument.

5) Instrument range should be based on the actual need to display the range of process objects or the actual range of change to determine. In addition to volumetric measurement for the level instrumentation, the normal level should generally be in the instrument range of about 50%.

6) Instrumentation accuracy should be selected according to process requirements, but for volumetric measurement of the level instrumentation, the accuracy level should be above 0.5.

7) for combustible gases, vapours and combustible dust and other explosive hazardous areas of the electronic level instrumentation. Should be determined according to the category of hazardous places and the degree of danger of the measured medium, select the appropriate explosion-proof structure or take other protective measures.

8) For corrosive gases and hazardous dust and other places of electronic level instrumentation, should be used according to environmental conditions, select the appropriate shell protection type.

Selection of Liquid Level and Interface Measuring Instruments

1.Differential Pressure Measuring Instrument

For continuous measurement of liquid level, differential pressure instruments are preferred. For interface measurement, differential pressure instrumentation can be used, but the total liquid level should always be higher than the upper pressure port. For the measurement of high precision requirements, the measurement system needs to be more complex and accurate operation, and general analogue instrumentation is difficult to achieve, you can use differential pressure intelligent transmission instrumentation, the accuracy of which is more than 0.2 level. For the density of the liquid under normal working conditions have significant changes, it is not suitable for the selection of differential pressure instrumentation. Corrosive liquids, crystalline liquids, viscous liquids, easy to vaporise liquids, liquids containing suspended solids should be selected flat flange differential pressure instrumentation. Highly crystalline liquid, high viscosity liquid, gelatinised liquid, precipitated liquid should be inserted flange differential pressure instrument. Above the measured medium level, if there are a lot of condensate and precipitate precipitation in the gas phase, or need to isolate the high temperature liquid from the transmitter, or need to strictly purify the measuring head when replacing the measured medium, double-flange differential pressure instrument can be selected. Corrosive liquids, viscous liquids, crystalline liquids, molten liquids, precipitated liquids, the liquid level in the difficult to use flange-type differential pressure instrumentation measurement, you can use the blowing or flushing method, with ordinary pressure gauges, pressure transducers or differential pressure transducers for measurement. For the ambient temperature, the gas phase may be condensed, the liquid phase may be vaporised, or the gas phase has the object of liquid separation, when it is difficult to use the flange-type differential pressure instrumentation and use the ordinary differential pressure instrumentation for measurement, it should be set up according to the specific circumstances, respectively, with the isolator, the separator, the vapour converter, the balancing vessel and other components, or the measurement of the pipeline heat preservation, accompanied by heat. When measuring the liquid level of boiler ladle with differential pressure instrument, temperature compensated double chamber balance vessel should be used. Differential pressure instrumentation of positive and negative migration should be considered in the selection of instrument range.

2.Float type measuring instrument

For the measurement range within 2000mm, the specific density of 0.5 ~ 1.5 of the liquid level continuous measurement, as well as the measurement range within 1200mm, the specific density difference of 0.1 ~ 0.5 of the liquid interface continuous measurement, it is appropriate to use the float type instrumentation. Vacuum object, easy to vaporise the liquid should use float type instrumentation. In situ level indication or adjustment of pneumatic float instrumentation is preferred. Float instrumentation must be used for clean liquids. Selection of float type instrumentation, when the accuracy requirements are high, the signal requires remote transmission, it is appropriate to choose the force balance type; when the accuracy requirements are not high, on-site indication or adjustment, it can be used to balance the displacement type. For the liquid level measurement of open storage tank, open storage tank, it is appropriate to use the inner float; for the liquid object which is not crystallised or viscous under the operating temperature, but may be crystallised or viscous under the ambient temperature, it is also appropriate to use the inner float. For the process equipment that does not allow stopping, the inner float should not be selected, but the outer float should be selected. For highly viscous, crystalline or high-temperature liquid objects, should not be selected for the external float. Inner float instrumentation in the container when the liquid disturbance is large, should be installed to prevent the impact of the disturbance of the smooth casing. Electric float instrumentation for the measured level fluctuations in frequent occasions, its output signal should be added dampers

3. Float type measuring instruments

For continuous measurement and volumetric metering of clean liquid level in large tanks, as well as for bit-type measurement of clean liquid level and interface in all types of tanks, float-type instruments should be used. Dirty liquids, as well as liquids frozen at ambient temperatures, should not use float type instruments. Continuous measurement of viscous liquids and multi-point measurement, also should not be used float type instrumentation. Float type instrumentation for interface measurement, the specific density of the two liquids should be constant, and the difference in specific density should not be less than 0.2. Internal float level instrumentation for large storage tank liquid level measurement, in order to prevent float drift, should be equipped with guiding facilities; in order to prevent the floats from being affected by the disturbance of the liquid level, should be added with a smooth casing. Large storage tank liquid level or volume of continuous measurement, a single storage tank or multi-storage tank with high requirements for measurement accuracy, it is appropriate to use photoconductive liquid level meter; general requirements for measurement accuracy of a single storage tank can be used with a steel belt float type liquid level meter. Requirements for high-precision continuous measurement of liquid level, interface, volume and quality of a single storage tank or multi-storage tank, should be selected tank measurement system. Open storage tank, open liquid storage tank liquid level multi-point level measurement, as well as corrosive, toxic and other hazardous liquids multi-point level measurement, it is appropriate to use magnetic float liquid level meter. Viscous liquid level measurement, it is appropriate to use lever float level controller.

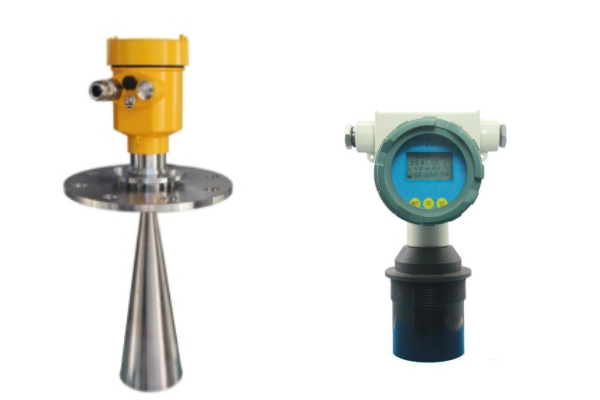

4. Acoustic measuring instruments

For ordinary level instrumentation is difficult to measure corrosive liquids, highly viscous liquids, toxic liquids and other liquid level of continuous measurement and level measurement, it is appropriate to use acoustic measuring instruments. Acoustic instrumentation of specific models, structure type, should be determined according to the characteristics of the measured medium and other factors. Acoustic instrumentation must be used to reflect and propagate sound waves of the container level measurement, shall not be used for vacuum containers. Should not be used for liquids containing gas bubbles and liquids containing solid particles. For internal obstacles affecting the propagation of sound waves of the container, should not be used acoustic instrumentation. For continuous measurement of liquid level acoustic instrumentation, if the measured liquid temperature, composition changes are more significant, should be considered to compensate for changes in the speed of sound wave propagation, in order to improve the accuracy of the measurement. The cable between the detector and the converter should be shielded cable, or consider the use of anti-electromagnetic interference measures.

5. Laser-based measuring instruments

For continuous measurement of the liquid level of vessels with complex structures or mechanical obstacles, as well as vessels that are difficult to install by conventional methods, laser-type measuring instruments should be used. For completely transparent liquids without reflection, laser type measuring instruments cannot be used.

Selection of Material Surface Measuring Instruments

1. Capacitive measuring instrument

For granular materials and powder materials, such as: coal, plastic monomer, fertiliser, sand and other material surface continuous measurement and bit-type measurement, it is appropriate to use capacitive measuring instruments. Detector extension cable should be shielded cable, or consider the use of anti-electromagnetic interference measures.

2. Sonic measuring instrument

For no vibration or vibration of small silo, hopper particle size of 10mm or less granular material level measurement, can choose the tuning fork level meter. For the particle size of 5mm or less powdery material material level measurement, should be used sound blocking type ultrasonic level meter. For micro-powdery materials for continuous measurement of the material surface and level measurement, it is appropriate to use reflective ultrasonic level meter. Reflective ultrasonic material level meter should not be used for dust filled silo, hopper material surface measurement, also should not be used for uneven surface material level measurement.

3. Resistive (electrical contact) measuring instruments

For good conductivity or poor conductivity, but contains water granular and powdery materials, such as: coal, coke and other material surface of the bit-type measurement, you can choose the resistance type measuring instrument. Must meet the product specification of the electrode to ground resistance values to ensure the reliability and sensitivity of the measurement.

4. Laser type measuring instrument

For the continuous measurement of the material surface of vessels with complex structures or mechanical obstacles, as well as vessels that are difficult to install by conventional methods, laser-type measuring instruments should be used. For non-reflective and completely transparent materials, laser-type measuring instruments cannot be used.

5. Rotary measuring instrument

For bearing pressure is small, no pulsating pressure of the silo, hopper, the material density of 0.2 or more granular and powdery material material surface bit type measurement, can choose to rotate the type of measuring instrument. The size of the rotor should be selected according to the specific density of the material. In order to avoid the impact of the material rotor caused by the instrument malfunction, should be set above the rotor protection plate.

6. Diaphragm type measuring instrument

For the silo, hopper granular or powder material material level of bit-type measurement, can choose the diaphragm type measuring instrument. Due to the action of the diaphragm is susceptible to the influence of powder adhesion and powder flow pressure, can not be used for higher precision requirements of the occasion.

7. Microwave measuring instrument

For high temperature, adhesion, corrosivity, toxicity of large lumps, granular materials and continuous measurement of the material surface level measurement, it is appropriate to use microwave measuring instruments. Not suitable for uneven surface level measurement.

8. Heavy hammer type measuring instrument

For the material level height, wide range of changes in large silos, bulk warehouses, and open or closed pressure-free container block, granular and adhesion of powder and granular materials in the material surface of the continuous measurement of the timing, should be used in the heavy hammer type measuring instrument. The form of the hammer should be selected according to the material size, dryness and humidity and other factors. For the material level measurement of silo and container with serious dust diffusion, heavy hammer type measuring instrument with blowing device should be used.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist