BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

I. Radar level meter: accurate penetration, fearless complex environment

Core advantages: non-contact measurement, resistance to high temperature, high pressure, corrosive media, accuracy up to ±1mm.

Application scenarios: chemical storage tanks, liquefied natural gas, strong volatile liquids.

Highlights:

- Millimeter wave/high-frequency radar penetrates vapor and foam interference and provides real-time feedback of liquid level;

- Intelligent algorithm automatically calibrates, reducing manual intervention;

- Applicable to explosion-proof area, high safety level.

II. Ultrasonic level meter: economical and efficient, intelligent and convenient

Core advantages: simple installation, low maintenance costs, suitable for non-contact continuous monitoring.

Application scenarios: water treatment tanks, oil depots, open storage tanks and corrosive liquids.

Points of Attention of ultrasonic level meter:

- Sound waves are susceptible to temperature and pressure fluctuations, need to be matched with a temperature compensation module

- Avoid using in vacuum or strong volatile media (acoustic wave attenuation)

- The king of cost-effective, the first choice for short and medium distance measurement.

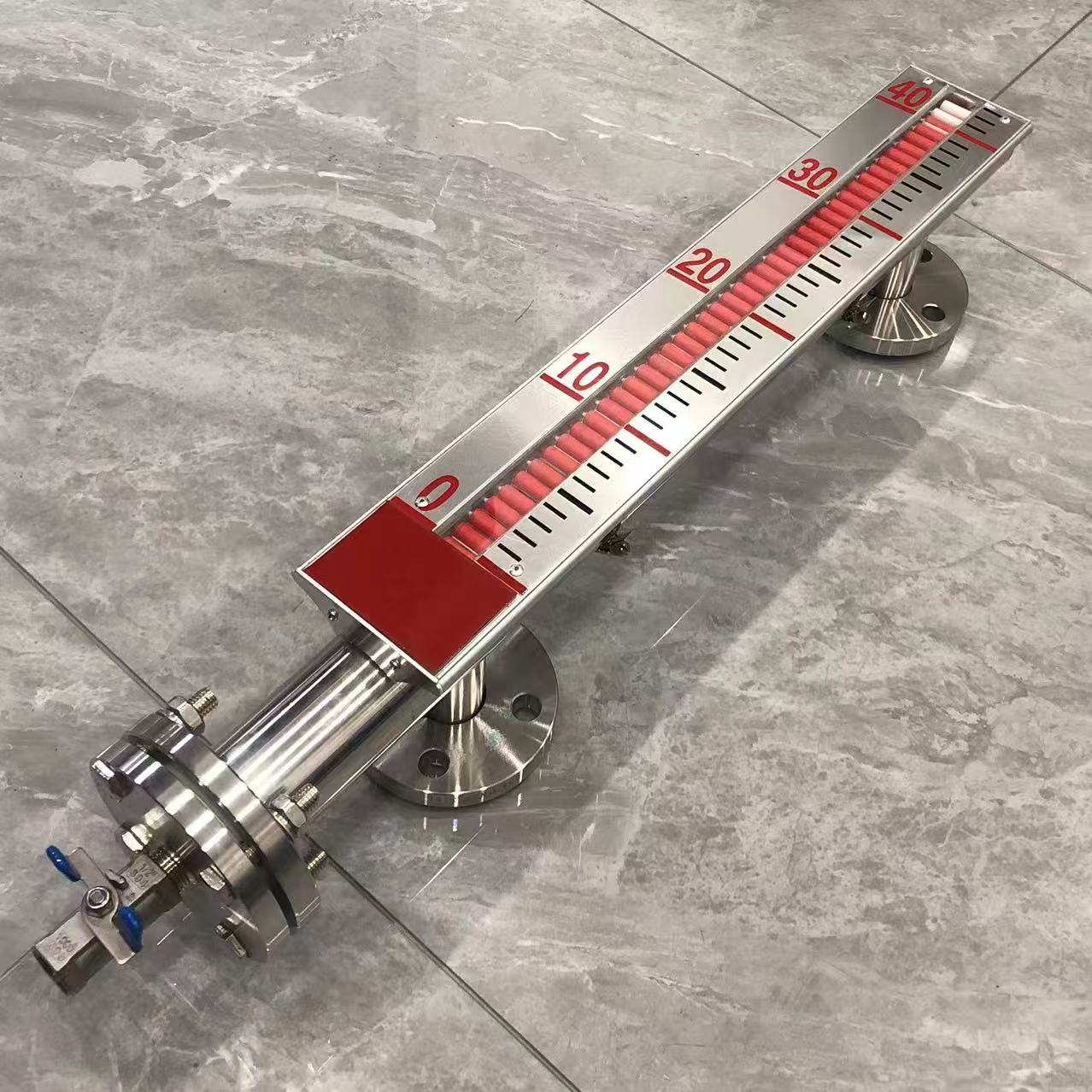

III. Magnetic Flip-Flop Level Gauge: Intuitive and Visual, Stable and Reliable

Core advantage: mechanical structure, directly display the liquid level height, without power supply.

Application scenarios: high temperature and high pressure vessels, flammable and explosive environments, local real-time monitoring conditions.

Upgrade program:

- Optional 4-20mA telecommunication signal to realize digital management.

- Double-color magnetic flap (red and white contrast) to improve visibility.

- Clean the float regularly to avoid magnetic impurity interference.

IV. Float Level Gauge: Simple Structure, Suitable for Extreme Environments

Core advantages: pure mechanical working principle, high temperature, high pressure, viscous liquid resistance.

Application scenarios: petroleum storage tanks, sewage ponds, high viscosity media (such as asphalt, slurry).

Optimization direction:

- Multi-float group design improves measurement accuracy .

- Stainless steel/PTFE is available for corrosive liquids.

- Float flexibility needs to be checked regularly to prevent jamming.

V. Pressure transmitter level measurement: indirect measurement, economical and flexible

Core advantage: liquid level conversion through the liquid static pressure, suitable for low-cost monitoring of closed containers.

Application scenarios: underground storage tanks, closed reactors, liquid level alarm systems.

Key points:

- Need to accurately set the density parameters of the medium.

- The installation position affects the accuracy (it is recommended to connect directly to the bottom).

- Match with temperature sensor to compensate for data error.

How to choose?

- High accuracy requirements: radar level meter (complex conditions) > ultrasonic (conventional conditions).

- Limited budget: pressure transmitter > float level meter.

- Safety and explosion-proof: magnetic flap level meter (local display) + radar (remote signal).

- Viscous/corrosive media: float level meter (material upgrade) or non-contact radar.

Tip: Combine the media characteristics, environmental conditions and automation needs, customized multi-technology integration solutions

(such as radar + magnetic flap double redundant system), to ensure production safety and efficiency maximization.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist